Introduction to laser technology

Laser technology has developed rapidly in recent decades and is now a key technology in many industries. A laser produces high-energy, coherent light that is used in a variety of applications. From precision machining in manufacturing to medical applications and communication, lasers have become an indispensable part of modern technology.

Lasers are not just tools for material processing; they also play a central role in telecommunications, medicine and even consumer electronics. The different types of lasers have their own unique properties and applications, which vary depending on the requirements and industry.

Fiber Laser Technology

What is a fiber laser?

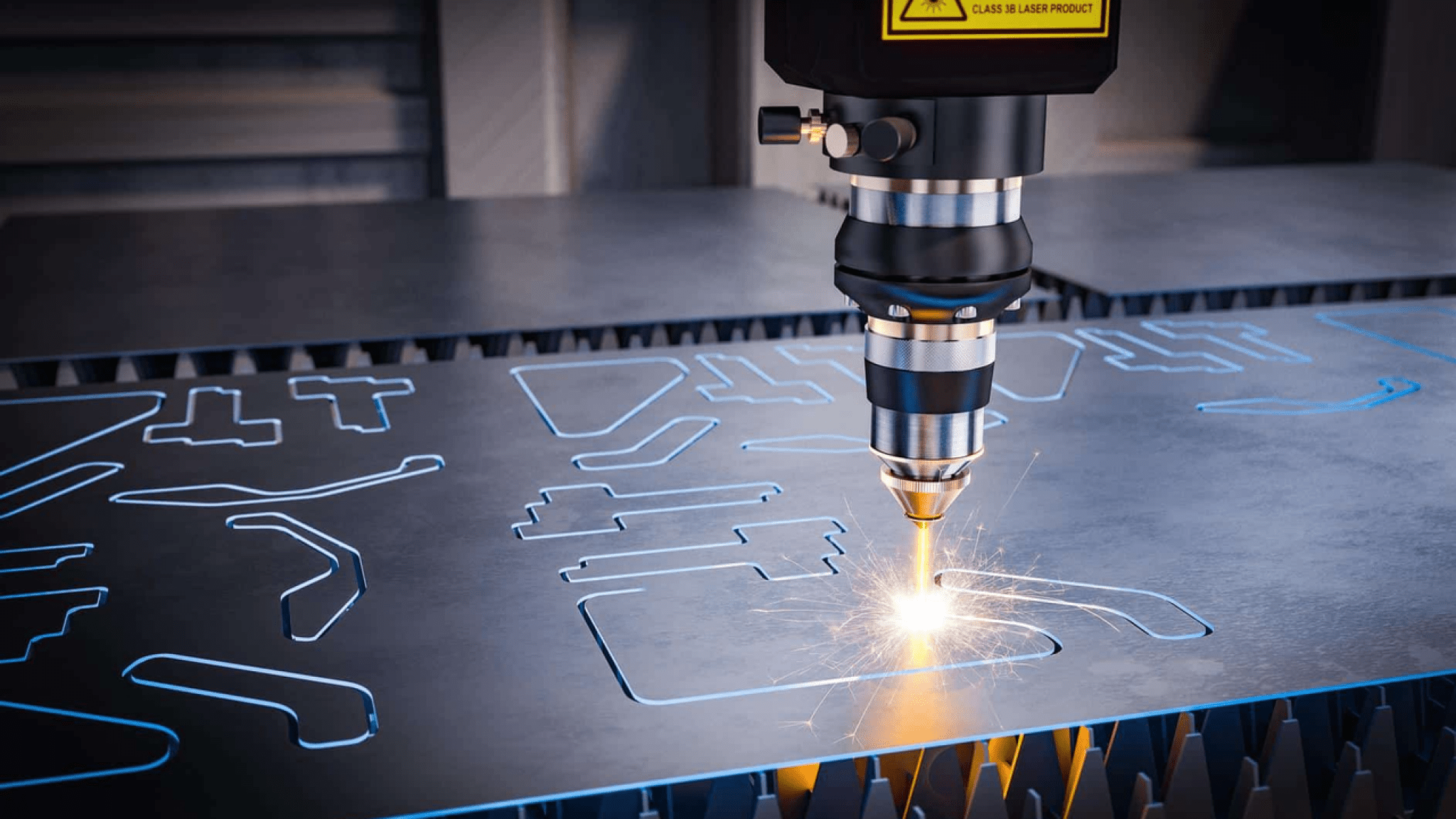

Fiber lasers are one of the most popular and advanced laser technologies used in industrial manufacturing. They consist of an active fiber laser material coupled with an optical fiber to efficiently guide the light. Fiber lasers are known for their high efficiency, precision, and durability, making them ideal for demanding applications such as cutting and welding metals.

Main Components and Function

A fiber laser consists of a special fiber optic material doped with rare earth elements, usually ytterbium or erbium. These materials enable light to be amplified and produce coherent laser radiation. The light source is guided to the material being processed via an optical fiber, enabling very precise processing.

Fiber Laser Applications

Fiber lasers are commonly used in metalworking, welding, engraving, and marking. They are ideal for high-precision work and are widely used in the automotive, aerospace, and electronics industries. Due to their high efficiency and precision, they can process even the smallest details while minimizing material loss.

Diode Laser Technology

What is a diode laser?

Diode lasers, also known as semiconductor lasers, are compact and efficient lasers based on semiconductor technology. They have a wide variety of applications and are often used as light sources in medical devices, barcode scanners, and communications devices. Diode lasers are a popular choice due to their compact design and cost-effectiveness.

How Diode Lasers Work

Diode lasers work by exciting electrons in a semiconductor material, which emits light when electrons fall from a higher to a lower energy level. This emission is amplified by a crystal, usually made of gallium arsenide, resulting in a powerful and directed beam of light.

Applications

Diode lasers are often used in medical technology, particularly ophthalmology and dermatology. They also find applications in telecommunications, barcode scanners, and as pump sources for other types of lasers. Their versatility and compactness make them ideal for numerous applications.

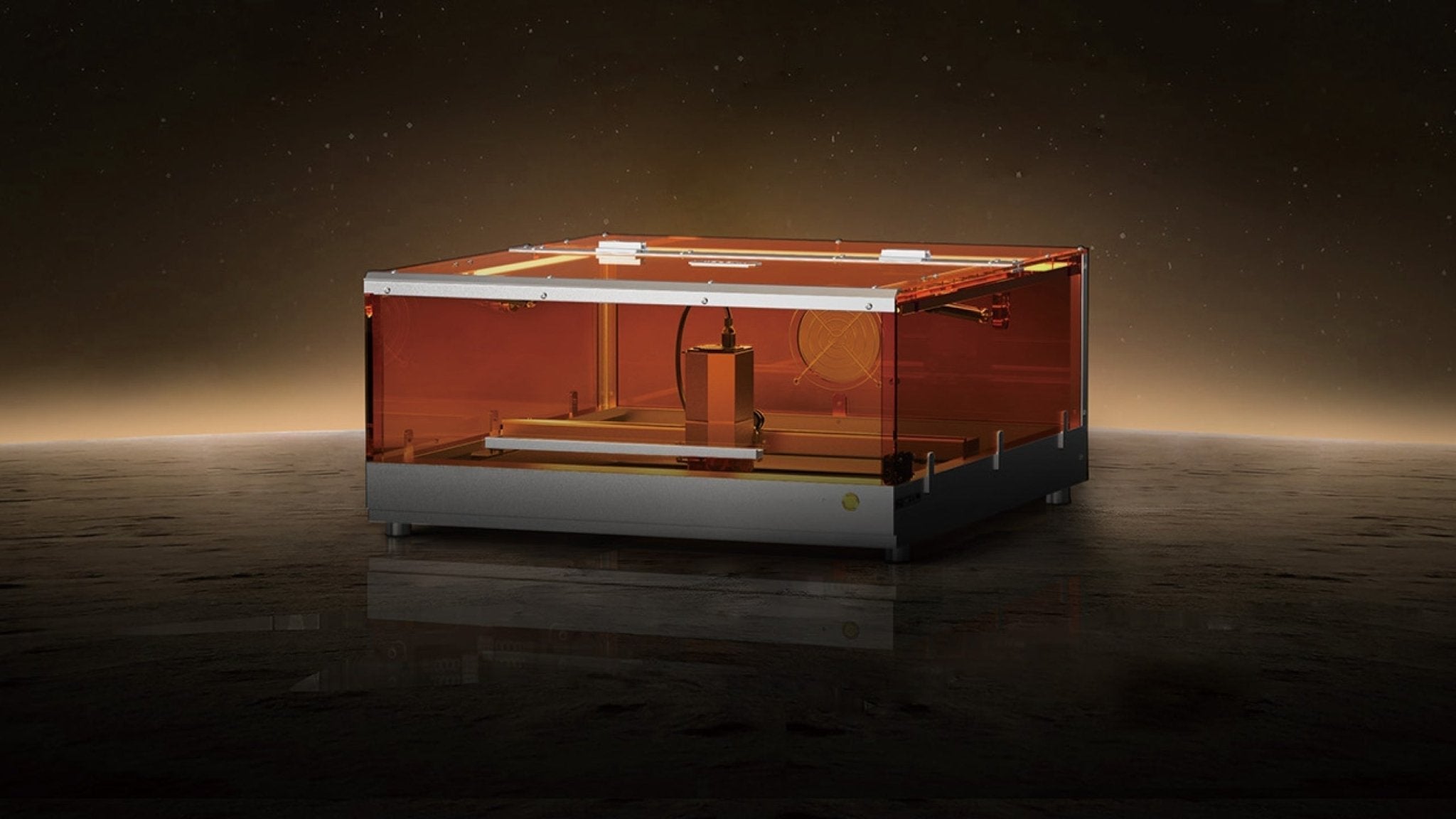

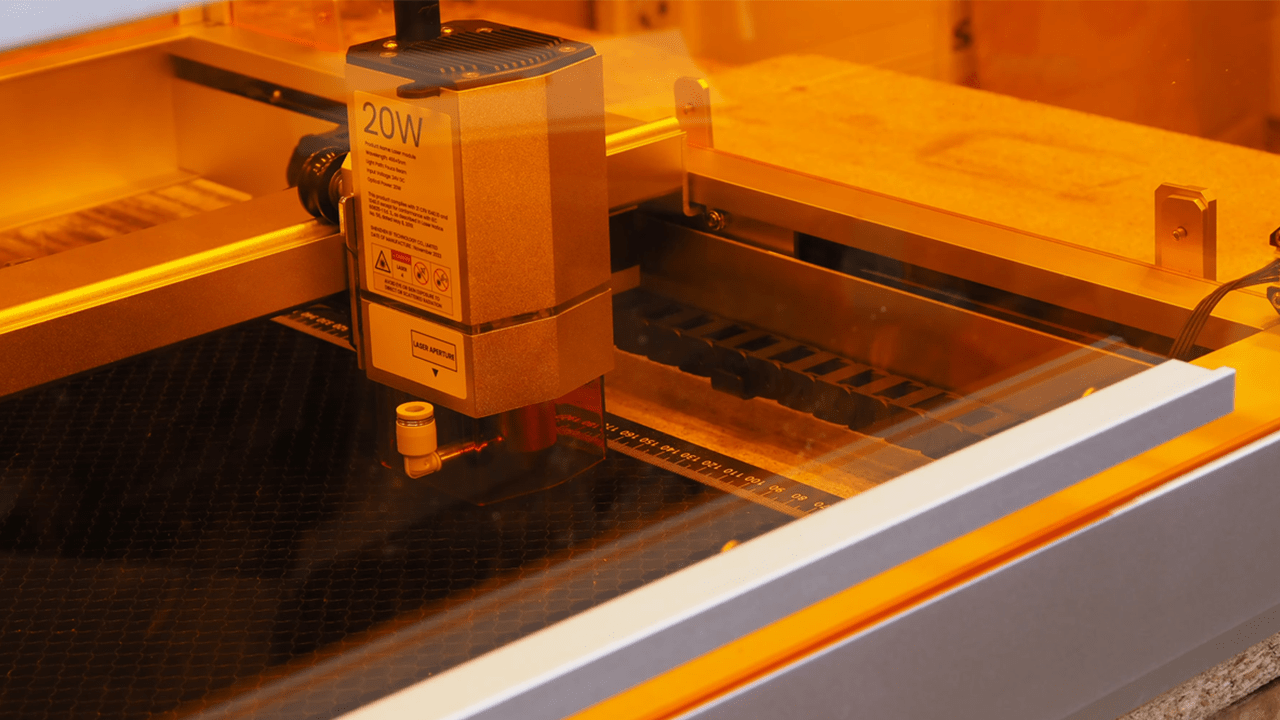

Our Top Recommendation -- TOOCAA L2

The TOOCAA L2 Diode Laser Engraver & Cutter is a powerful and versatile laser machine designed for creators and small businesses. With its large 400x400mm work area and ultra-fine 0.01mm precision, this engraver handles everything from delicate jewelry to thick wood cutting with professional results. The integrated smart air assist system ensures clean cuts while extending laser life, and its plug-and-play compatibility with TOOCAA Studio/LightBurn/LaserGRBL software makes operation effortless. Built with a durable aluminum frame, the L2 combines industrial performance with beginner-friendly features like auto-focus, making it perfect for engraving wood, acrylic, leather, anodized metals and more. Whether you're crafting custom signs, personalized gifts or prototyping designs, the TOOCAA L2 delivers studio-quality results in a compact desktop package.

Discover how this affordable yet powerful diode laser machine can bring your creative visions to life.

JPT Laser Technology

Introduction to JPT Lasers

JPT is a renowned manufacturer of laser sources, particularly known for precision machining and material marking. JPT laser technology is characterized by high reliability, long lifetime, and excellent performance, making it extremely suitable for industrial applications. The company specializes in fiber lasers, which are particularly widely used in the electronics and jewelry industries.

Special Features of JPT Lasers

JPT lasers are known for their high beam quality and precision. They have stable output power and good adaptability for demanding industrial processes. These properties make JPT lasers a popular choice for applications requiring high accuracy and detail.

Areas of Application

JPT lasers are primarily used in precision marking and engraving, especially in industries such as electronics, jewelry manufacturing, and mechanical engineering. They are often used for fine engraving, metal and plastic marking, and micromachining.

MOPA Laser Technology

What is a MOPA laser?

A MOPA (Master Oscillator Power Amplifier) laser is a special type of fiber laser that offers high flexibility in terms of pulse width and duration. These lasers are particularly useful for processing delicate materials or for applications that require precise control of the laser pulse duration. MOPA lasers are particularly suitable for tasks that require high precision.

MOPA vs. Fiber Laser

Compared to conventional fiber lasers, a MOPA laser offers increased control over the pulse duration. This control makes it possible to process various surface structures without heat damage to the material. This feature is particularly useful for applications that require fine detail, such as marking plastics or applying colors to metal surfaces.

Applications

MOPA lasers are widely used in fine marking and processing heat-sensitive materials. They are often used for machining electronic parts, jewelry manufacturing, and in the automotive industry, especially when precise and gentle material processing is required.

CO2 Laser Technology

What is a CO2 laser?

CO2 lasers are among the most powerful lasers for processing non-metallic materials. They are based on a gas mixture consisting primarily of carbon dioxide (CO2). These laser types are particularly suitable for cutting, engraving, and marking organic materials such as wood, acrylic, and leather.

How CO2 Lasers Work

A CO2 laser generates light by passing electrical energy through a gas mixture containing CO2, nitrogen, and helium. When electrically excited, these gases produce an intense laser beam in the infrared spectral range. This beam is then focused on the material being processed and can produce precise cuts or engravings.

Industrial Applications of CO2 Lasers

CO2 lasers are particularly popular in woodworking, the textile industry, and model making. Due to their high power and suitability for organic materials, they are ideal for cutting wood, plastics, and textiles. However, they are also used in medicine, for example for skin regeneration.

Comparing Different Laser Types

Choosing the right laser type depends on several factors, including power, efficiency, material compatibility, and precision. The following table provides an overview of the differences:

-

Power and Efficiency: Fiber and CO2 lasers typically offer the highest power, with fiber lasers being best suited for metals and CO2 lasers for organic materials.

-

Material Compatibility: Diode and CO2 lasers are better suited for non-metallic materials, while fiber and MOPA lasers are ideal for metal processing.

-

Cost and Maintenance: Diode lasers are generally the most cost-effective and have the lowest maintenance costs, while fiber and MOPA lasers are more expensive but have a longer lifespan.

-

Precision and Speed: MOPA and fiber lasers offer the highest precision and are ideal for applications requiring detailed work.

Factors to Consider When Choosing a Laser Type

Material and Application Requirements

When choosing a laser, it's important to consider the material requirements and the application. For example, a fiber laser is suitable for cutting and engraving metals, while a CO2 laser is the best choice for wood and plastics.

Budget and Cost-Effectiveness

Budget also plays an important role. While diode lasers are generally inexpensive and efficient, MOPA and fiber lasers, although more expensive, can save costs in the long run due to their precision and durability.

Technical Specifications

The wavelength, power, and beam quality of the laser are key technical factors that influence the efficiency and quality of processing. Different laser types offer different wavelengths and beam profiles, which vary in effectiveness depending on the material.

Innovations and Trends in Laser Technology

Miniaturization and Portability

Developments in laser technology have made lasers smaller, more portable, and more efficient. Compact laser systems allow them to be used in applications that were previously impossible due to the size of the machines.

Advanced Precision Capabilities

New techniques and improved beam quality have greatly increased the precision of laser processing. Specialized laser systems now enable ultra-fine processing, which is crucial for applications such as microchip and medical device manufacturing.

Sustainability and Environmentally Friendly Options

Eco-friendly lasers with low energy consumption and CO2 emissions are becoming increasingly popular. These innovations support sustainable production and enable companies to reduce their environmental impact.

Practical Applications of Different Laser Types

Manufacturing and Metalworking

Fiber lasers and MOPA lasers are widely used in metalworking due to their high precision and efficiency. They are suitable for cutting, engraving, and welding metals and are used in the automotive, aerospace, and heavy industries.

Medical and Cosmetics

CO2 and diode lasers have proven useful in medicine and cosmetics, particularly in dermatology and ophthalmology. Diode lasers are often used for hair removal and laser eye surgery, while CO2 lasers are used for skin resurfacing and minor surgical procedures.