We have prepared a beautiful random material package, as well as pre-stored case files TF card, you can experience the production of the first work through the operation of the guide, you can also visit the TOOCAA case material link: https://www.toocaa.com/pages/file-library, or scan the QR code, download more case files! files. Follow the instructions below to start your first project!

Preparation

You will need to prepare the items below:

| Items |

Diagram |

|

TOOCAA L2 |

|

Computer |

|

3mm Basswood boards |

|

An Aluminium Plate |

|

TF Card |

|

Card Reader |

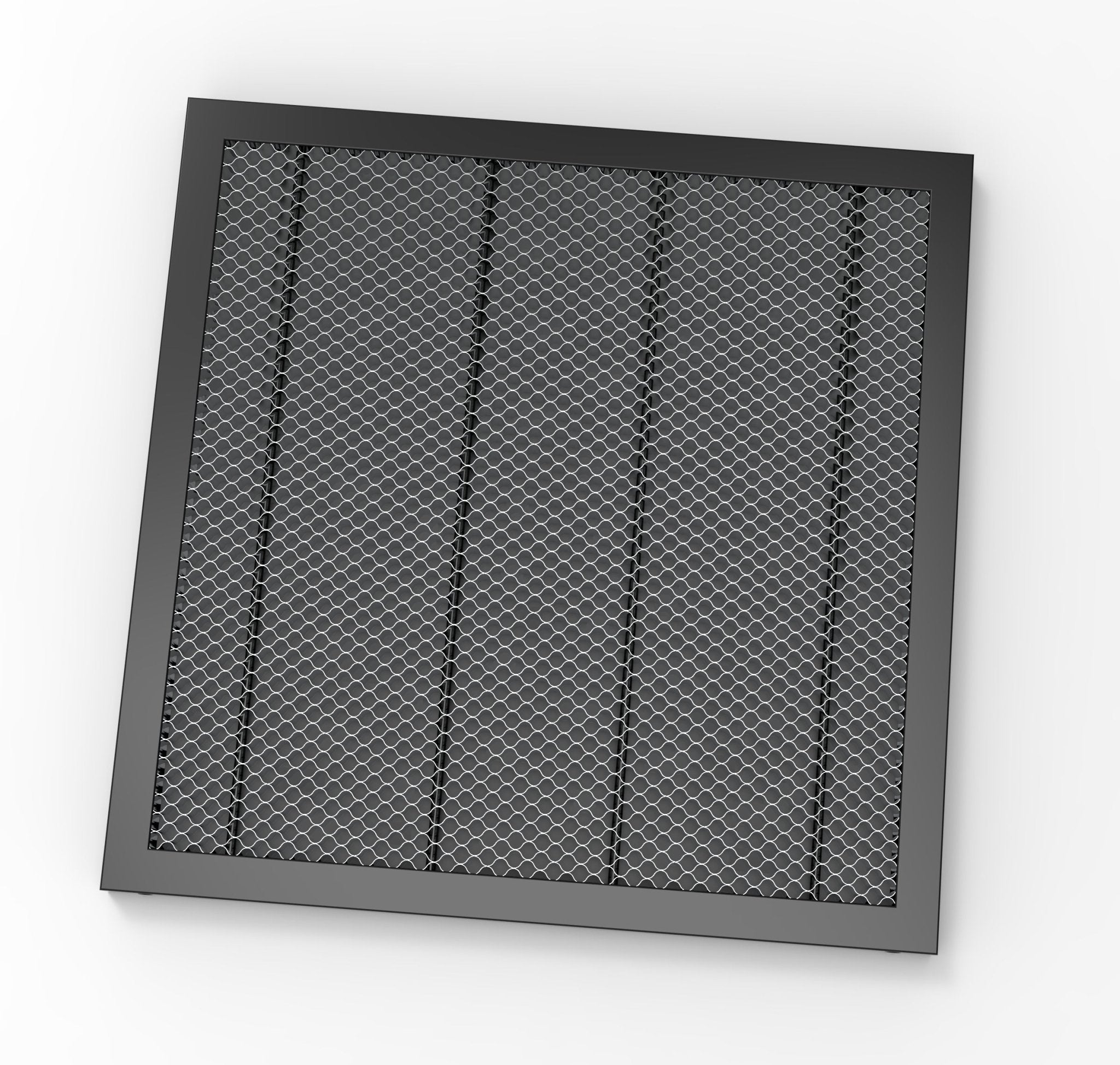

Step1/11 the smart protection shield and place the aluminium plate in the working area of the laser cutting machine..

Step2/11 Place the 3mm thick, A4 sized basswood board from the kit on top of the aluminium plate.

Step3/11 Lower the fixed focus lever of the laser module.

Step4/11 Pull the trigger upwards.

Step5/11 Adjust the position of the laser module so that the tip of the fixed focus lever falls onto the basswood board.

Step6/11 Spanner down to hold the laser head in place.

Step7/11 Retract the fixed focus lever.

Step8/11 Close the smart protection shield.

Step9/11 Connect the fan power adapter.

Step11/11 Plug the power adapter connector into the power connector.

Make The Case Files

TOOCAA L2 supports both LightBurn and LaserGRBL. All of our cases use LightBurn software and we recommend that you use LightBurn first.

Step1/16 Insert the TF card into the computer, in the following operation we need to use the "TOOCAA_L2.lbdev" file and "TOOCAA_L2_Case(10W)V1.0.dxf" file in the TF card.

Step2/16 Open LightBurn and click “Devices”.

Step3/16 Click "Import" to import the .lbdev configuration file: TOOCAA_L2.lbdev from the TF card.

Step4/16 After importing, select TOOCAA L2 in the device list and click OK for successful configuration.

Step5/16 Click on "Edit-Settings".

Step6/16 Select "mm/min" and click OK.

Step7/16 Click on the "File" menu and select "Import" from the drop-down list to open the file selection screen.

Step8/16 Locate the "TOOCAA_L2_Case(10W)V1.0.dxf" file on the TF card and open it.

Step9/16 The import file is completed as shown in the figure.

Step10/16 Set the laser movement speed and power.

|

Material |

Laser Module |

Mode |

Speed |

Power |

|

3mm Basswood |

10W Laser Module |

Cut |

350mm/min |

100% |

|

3mm Basswood |

10W Laser Module |

Engrave |

2000mm/min |

100% |

|

3mm Basswood |

10W Laser Module |

Fill |

5000mm/min |

60% |

|

3mm Basswood |

20W Laser Module |

Cut |

450mm/min |

100% |

|

3mm Basswood |

20W Laser Module |

Engrave |

8000mm/min |

100% |

|

3mm Basswood |

20W Laser Module |

Fill |

8000mm/min |

60% |

![]() The 3mm basswood board is used in this case. For more information about the parameter settings of the material, please refer to the Common Parameter Settings page on the TOOCAA website. Common parameter setting page URL: https://www.toocaa.com/pages/material-settings-for-toocaa-machines

The 3mm basswood board is used in this case. For more information about the parameter settings of the material, please refer to the Common Parameter Settings page on the TOOCAA website. Common parameter setting page URL: https://www.toocaa.com/pages/material-settings-for-toocaa-machines

Step11/16 Select all the works and click on the "Save GCode" option.

Step12/16 Select the disk for the TF card to save the work to the TF card.

Step13/16 Insert the TF card into the card slot.

Step14/16 Switch on the power.

Step15/16 Tap the button and release it to view the laser module pre-travelling the work area.

Step16/16 Double-click the button and the laser cutter starts working.