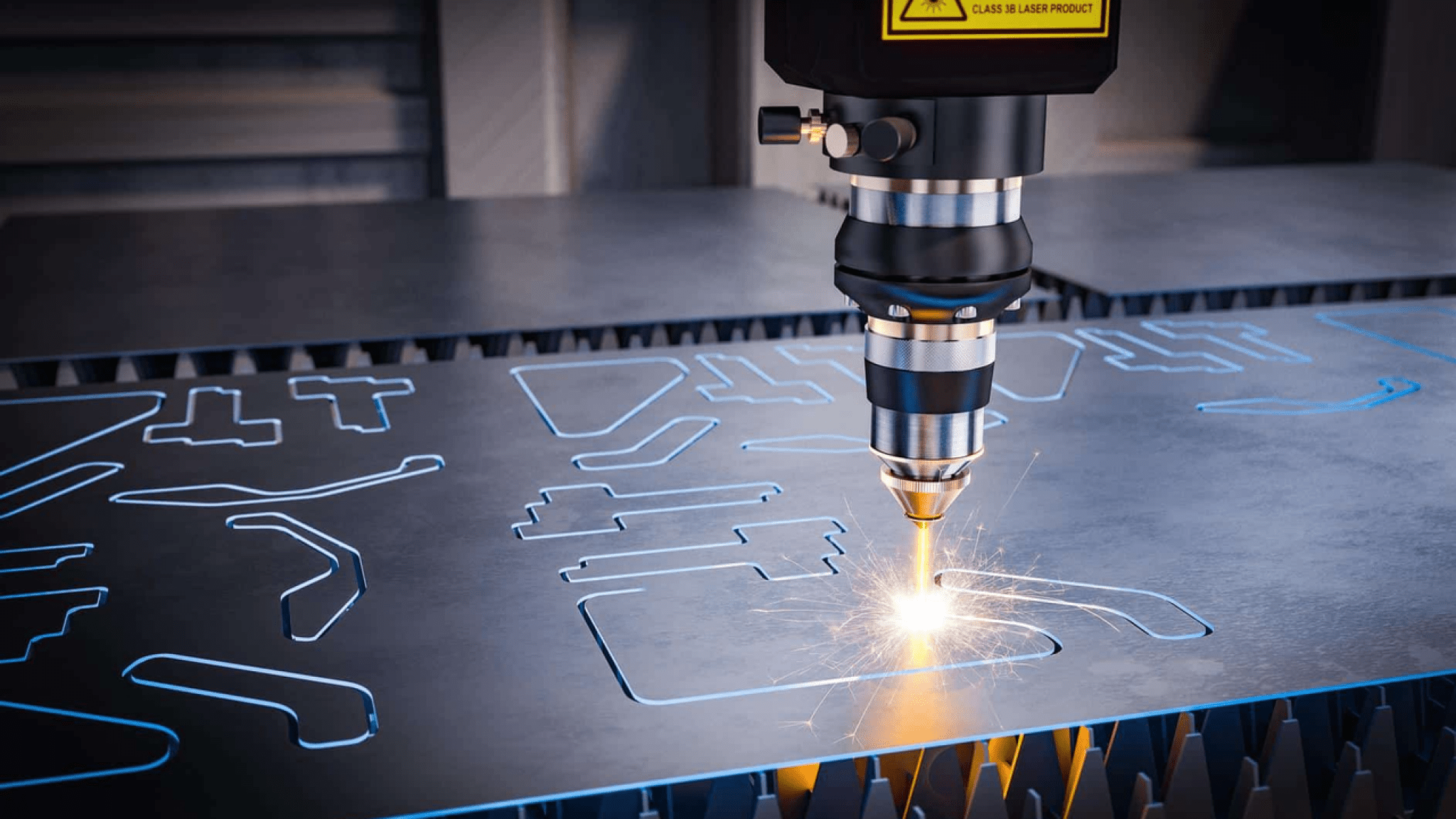

Choosing the right laser for aluminum engraving can significantly impact the quality and efficiency of your work. Each laser type—CO2, Fiber—offers unique advantages. Fiber lasers excel in precision and speed, while CO2 lasers are better suited for non-metals unless pre-treated. In 2025, advancements in laser technology make it essential to evaluate factors like efficiency, cost, and durability. For engraving aluminum, fiber lasers stand out due to their high-intensity beam and ability to handle laser engraving material aluminum with precision and minimal upkeep.

Overview of Laser Types for Aluminum Engraving

CO2 Lasers

CO2 lasers are a popular choice for engraving due to their versatility. These lasers operate at a longer wavelength, which is not easily absorbed by metals like aluminum. However, you can still use them effectively on aluminum if the surface is pre-treated or combined with a metal marking spray. This makes CO2 lasers a viable option for engraving aluminum when specific preparations are made.

Tip: Pretreating aluminum or using a marking spray ensures better results with CO2 lasers.

CO2 lasers are also widely used for non-metallic materials such as acrylics, wood, and natural stone. Manufacturers who work with a variety of materials often prefer CO2 lasers for their adaptability. Additionally, these lasers are generally more affordable than fiber lasers, making them a cost-effective option for businesses with diverse engraving needs.

Advantages of CO2 Lasers for Aluminum Engraving:

-

Suitable for pre-treated aluminum surfaces.

-

Versatile across non-metallic materials.

-

More affordable compared to fiber lasers.

Limitations:

-

Requires pretreatment for bare aluminum.

-

Less effective on untreated metal surfaces.

Fiber Lasers

Fiber lasers are the top choice for engraving aluminum. They deliver unmatched precision and speed, making them ideal for dense metals. The high-intensity beam of a fiber laser ensures clean and sharp engravings, while its wavelength is easily absorbed by aluminum. This results in efficient and high-quality engraving.

Fiber lasers are also known for their durability and low maintenance. You can rely on them for consistent performance over time, reducing operational costs. Their ability to produce high-contrast markings makes them perfect for applications requiring detailed designs or text.

Key Features of Fiber Lasers:

-

High-speed operation for efficient engraving.

-

Precision suitable for dense metals like aluminum.

-

Minimal maintenance requirements.

-

Long lifespan, reducing overall costs.

Compared to CO2 lasers, fiber lasers are more efficient for engraving aluminum. They amplify light through optical fibers, creating a concentrated beam that works exceptionally well on metal surfaces. While they may have higher upfront costs, their lower operating expenses and superior performance make them a worthwhile investment.

Other Laser Types (e.g., Diode, UV, MOPA Fiber)

Other laser types, such as diode, UV, and MOPA fiber lasers, offer unique features but come with limitations for aluminum engraving. For example, UV lasers are highly precise but are better suited for plastics, glass, and coated metals. They struggle with penetration depth on bare aluminum, making them less effective for this application.

|

Laser Type |

Limitation |

|---|---|

|

UV Lasers |

High cost; limited to shallow penetration on metals. |

|

Diode Lasers |

Limited power; not ideal for dense metals like aluminum. |

|

MOPA Fiber Lasers |

More expensive than standard fiber lasers; niche use cases. |

If you need a specialized laser for unique materials or coatings, these options might work. However, for engraving aluminum, fiber lasers remain the most practical and efficient choice.

Key Factors for Choosing a Laser

Precision and Engraving Quality

Precision plays a critical role in achieving high-quality results when engraving aluminum. Several factors influence the accuracy of laser engravers:

-

The size of the focused beam spot determines how fine the details can be.

-

The optical system's quality and thermal control technology ensure consistent performance.

-

Machines with lead screw drives provide better accuracy than those using rack gear systems.

-

The maximum acceleration of your CNC router impacts the smoothness of vector engravings.

-

Assembly techniques and technician expertise also affect the final output.

-

Square engraving machines generally offer higher precision than compass-based systems.

Fiber lasers excel in precision due to their high-intensity beam and efficient control. They produce sharp, high-contrast markings on aluminum, making them ideal for intricate designs. In contrast, CO2 lasers require pre-treatment to achieve similar results, and diode lasers lack the power for dense metals.

|

Laser Type |

Characteristics |

Impact on Engraving Quality |

|---|---|---|

|

Fiber Lasers |

High-intensity beam, precise and clean engraving, efficient, long lifespan |

Produces sharp, high-contrast markings |

|

CO2 Lasers |

Longer wavelength, effective on coated aluminum with pre-treatment |

Less effective on bare aluminum, but versatile with coatings |

|

UV Lasers |

Very short wavelength, high precision, minimal heat affected zone |

Ideal for intricate details and fine features |

For the best results, fiber lasers remain the top choice for laser engraving material aluminum.

Cost and Affordability

The cost of laser engravers varies significantly depending on the type and application. Fiber lasers are more expensive upfront, with prices ranging from $1,399 to $25,000 for desktop models and up to $120,000 for industrial systems. CO2 lasers, on the other hand, are more affordable, starting as low as $200 and going up to $10,000.

|

Laser Type |

Price Range |

|---|---|

|

Fiber |

$120,000 (industrial) to $1,399 - $25,000 (desktop) |

|

CO2 |

$200 to $10,000 |

While fiber lasers have a higher initial cost, they offer long-term savings due to minimal maintenance and lower operating expenses. Additionally, laser etching generates minimal waste and eliminates the need for harmful chemicals, making it a sustainable and cost-effective choice over time. CO2 lasers may seem more affordable initially, but their higher maintenance demands and limited efficiency on aluminum can increase costs in the long run.

Maintenance and Durability

Maintenance requirements and durability significantly impact the overall cost and usability of a laser engraver. Fiber lasers are known for their long lifespan and minimal upkeep. They can operate continuously without significant maintenance, making them ideal for industrial applications. Their wavelength is particularly effective for metals, ensuring high-contrast, durable markings on aluminum.

CO2 lasers, while versatile, require more frequent maintenance. Their optical components and cooling systems need regular attention, which can increase downtime and operational costs.

Fiber lasers stand out as the most durable option for laser engraving material aluminum. Their efficiency and reliability make them a worthwhile investment for both small-scale and industrial applications.

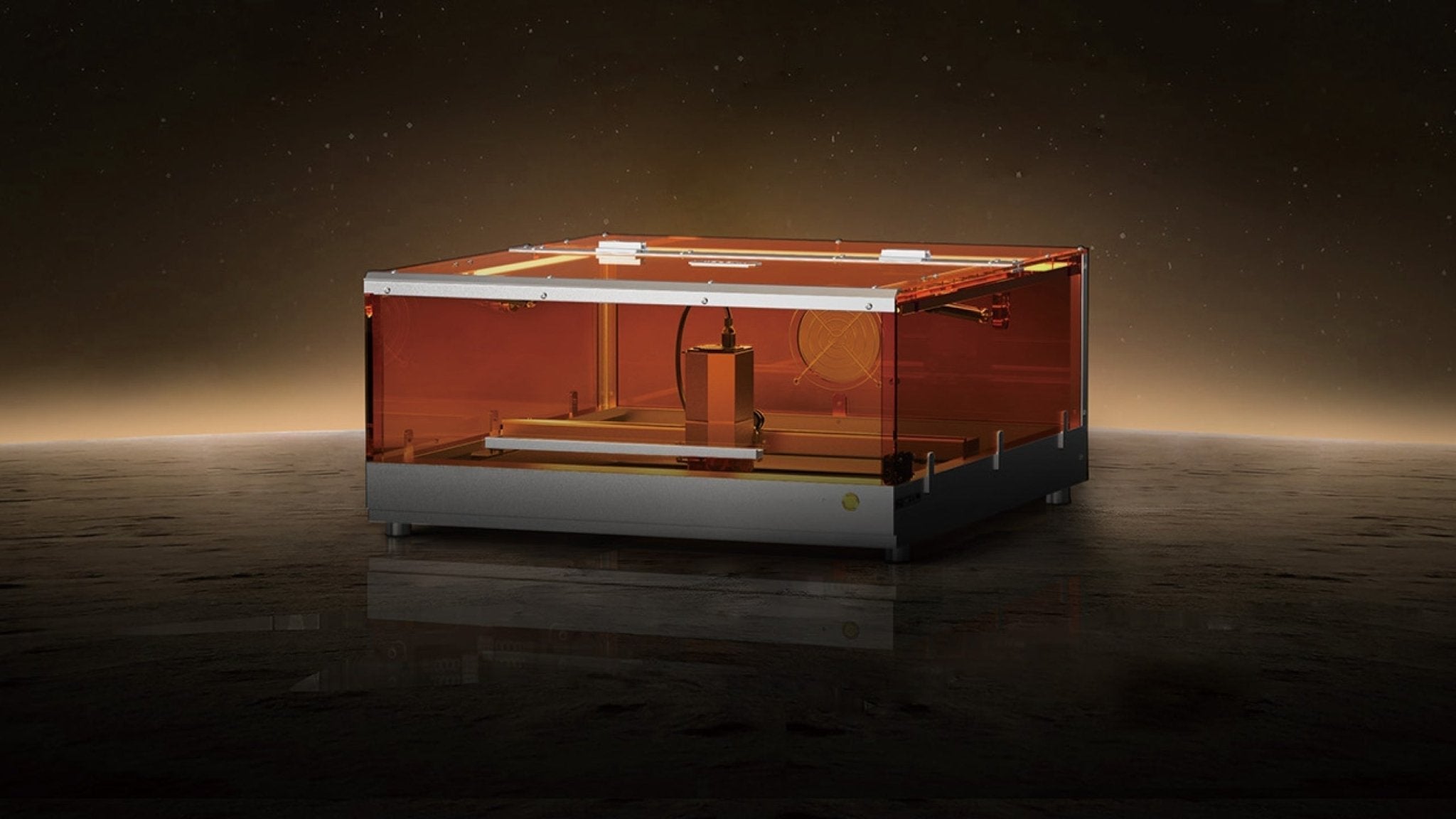

Screenshot from How to Engrave a BLACK MARK on Aluminum with a Fiber Laser | Fiber Laser Tutorials, by Laser Everything, available on YouTube

Comparison of Laser Types for Aluminum Engraving

CO2 Lasers: Pros and Cons

CO2 lasers offer versatility, but they face challenges when engraving aluminum. Their longer wavelength struggles with direct absorption by metals, requiring pre-treatment or marking sprays for effective results. This makes them less efficient for bare aluminum but suitable for coated or treated surfaces.

Advantages of CO2 Lasers:

-

Affordable compared to fiber lasers.

-

Versatile for non-metallic materials like wood and acrylic.

-

Widely available and easy to source.

Challenges of CO2 Lasers:

|

Challenge |

Description |

|---|---|

|

Initial Cost |

High-quality systems can be expensive to purchase and set up. |

|

Material Limitations |

Certain aluminum grades reflect the laser beam, causing inconsistent results or equipment damage. |

|

Surface Damage Risk |

Improper settings may burn or melt the aluminum surface. |

|

Limited Depth |

Engraving typically affects only the surface layer, limiting depth. |

|

Skill Required |

Operators need training to adjust settings for optimal results. |

|

Energy Consumption |

CO2 lasers consume significant energy, increasing operating costs. |

|

Safety Concerns |

Fumes and high-powered lasers pose health and safety risks. |

If you work with multiple materials and need a cost-effective option, CO2 lasers might suit your needs. However, their limitations on untreated aluminum make them less practical for this specific application.

Fiber Lasers: Pros and Cons

Fiber lasers excel in aluminum engraving due to their precision and efficiency. Their high-intensity beam easily penetrates aluminum, producing sharp, high-contrast markings. These lasers are ideal for industrial applications where speed and durability are critical.

Benefits of Fiber Lasers:

-

High precision for intricate designs.

-

Durable and permanent marks resistant to wear and corrosion.

-

Fast processing for large-scale projects.

-

Cost-effective over time with minimal maintenance.

-

Environmentally friendly, producing no hazardous fumes.

-

Customizable for detailed engravings.

Fiber lasers also have a long lifespan, reducing downtime and operational costs. Their ability to handle dense metals makes them the top choice for laser engraving material aluminum.

Drawbacks of Fiber Lasers:

|

Drawback |

Description |

|---|---|

|

Initial Cost |

High upfront investment, especially for industrial-grade systems. |

|

Material Limitations |

Certain aluminum grades may reflect the laser beam, requiring adjustments to avoid damage. |

|

Surface Damage Risk |

Improper settings can burn or melt the aluminum surface. |

|

Limited Depth |

Engraving typically affects only the surface layer, not providing significant depth. |

|

Skill Required |

Operators need expertise to adjust settings for different aluminum types. |

|

Energy Consumption |

Fiber lasers require significant energy, leading to higher operating costs. |

|

Safety Concerns |

Handling high-powered lasers and fumes requires strict safety measures. |

For industrial applications, fiber lasers provide unmatched performance. Their precision and efficiency justify the higher initial cost, especially for businesses focused on aluminum engraving.

Other Laser Types: Pros and Cons

Other laser types, such as diode and UV lasers, serve niche purposes but fall short for aluminum engraving. Diode lasers lack the power for dense metals, while UV lasers excel in precision but struggle with penetration depth.

Comparison of Other Laser Types:

-

Diode Lasers: Suitable for simple tasks and low-power applications. They are not ideal for dense metals like aluminum.

-

UV Lasers: Offer high precision and minimal heat-affected zones, making them suitable for delicate aluminum materials. However, they are less effective for deep engraving.

-

MOPA Fiber Lasers: Provide flexibility for marking and engraving but come at a higher cost than standard fiber lasers.

If you need a specialized laser for unique applications, these options might work. However, for consistent and efficient results on aluminum, fiber lasers remain the most practical choice.

Recommendations for 2025

Best Laser for Small-Scale Applications

For small-scale aluminum engraving, you need a laser that balances affordability, portability, and efficiency. Diode lasers stand out as an excellent choice for DIY projects or hobbyists. These lasers are compact and cost-effective, making them ideal for personal use.

-

Portability: Diode lasers are lightweight and easy to transport.

-

Cost-Efficiency: They offer a budget-friendly option for beginners.

-

Ease of Use: Their simple setup makes them accessible for non-professionals.

If you require more versatility, CO2 lasers can also work for small-scale applications. However, they may need additional preparation, such as using marking sprays, to engrave aluminum effectively. Fiber lasers, while precise, often exceed the budget for small-scale needs.

Tip: For DIY enthusiasts, a diode laser engraver provides the best value in 2025.

Best Laser for Industrial Applications

In industrial settings, you need a laser that delivers speed, precision, and durability. Fiber lasers dominate this category due to their unmatched efficiency and ability to handle dense metals like aluminum.

-

High Efficiency: Fiber lasers engrave aluminum quickly without compromising quality.

-

Durability: These lasers require minimal maintenance, ensuring consistent performance.

-

Precision: They produce sharp, high-contrast markings, even on intricate designs.

CO2 lasers also play a role in industrial applications. Their flexibility makes them suitable for engraving coated aluminum or other materials. However, they fall short in speed and depth compared to fiber lasers.

Note: For large-scale operations, fiber lasers remain the most reliable and cost-effective option in 2025.

Tailoring the Choice to Specific Needs

Your specific requirements, such as engraving speed or depth, should guide your laser selection. The table below highlights how different laser types perform based on power levels and applications:

|

Laser Type |

Power Level |

Best For |

|---|---|---|

|

Fiber Laser |

High |

Quickly engraving metals |

|

CO2 Laser |

Low |

Softer materials like wood |

|

UV Laser |

Medium |

High-precision engraving on delicate surfaces |

If you prioritize speed, fiber lasers excel in processing aluminum efficiently. For delicate or coated surfaces, UV lasers provide precision without damaging the material. CO2 lasers work best for softer materials but can engrave aluminum with proper preparation.

Tip: Always match the laser type to your project's specific demands for optimal results.

By understanding your needs and the strengths of each laser type, you can make an informed decision. Whether you focus on small-scale projects or industrial production, the right laser ensures high-quality results.

Choosing the right laser for aluminum engraving in 2025 depends on your specific needs. Fiber lasers stand out for their precision, efficiency, and low maintenance, making them ideal for industrial applications. CO2 lasers offer versatility and affordability, especially for coated aluminum with pre-treatment. For delicate materials, UV lasers provide unmatched precision with minimal heat impact. Diode lasers remain a practical choice for small-scale projects due to their compact design and cost-effectiveness.

Key Takeaways for 2025:

Fiber Lasers: Best for industrial use with high-quality results.

CO2 Lasers: Flexible and effective for coated aluminum.

UV Lasers: Perfect for intricate designs on delicate materials.

Diode Lasers: Compact and efficient for smaller applications.

Before making a decision, evaluate your project requirements. Test different lasers on scrap materials to find the best fit. Consult experts to optimize settings like power, speed, and focus. Keep your equipment well-maintained and ensure proper ventilation to manage heat and dust. Staying informed about advancements will help you achieve consistent, high-quality results.

Tip: Tailor your choice to your specific needs and always test before committing to a purchase.

Finally I want to share this video to you. It is a tutorial on engraving black marks on aluminium using a fibre laser and Brilliance laser ink and covers the exact setup, procedure and demonstration of the results, with an emphasis on their durability and affordability.