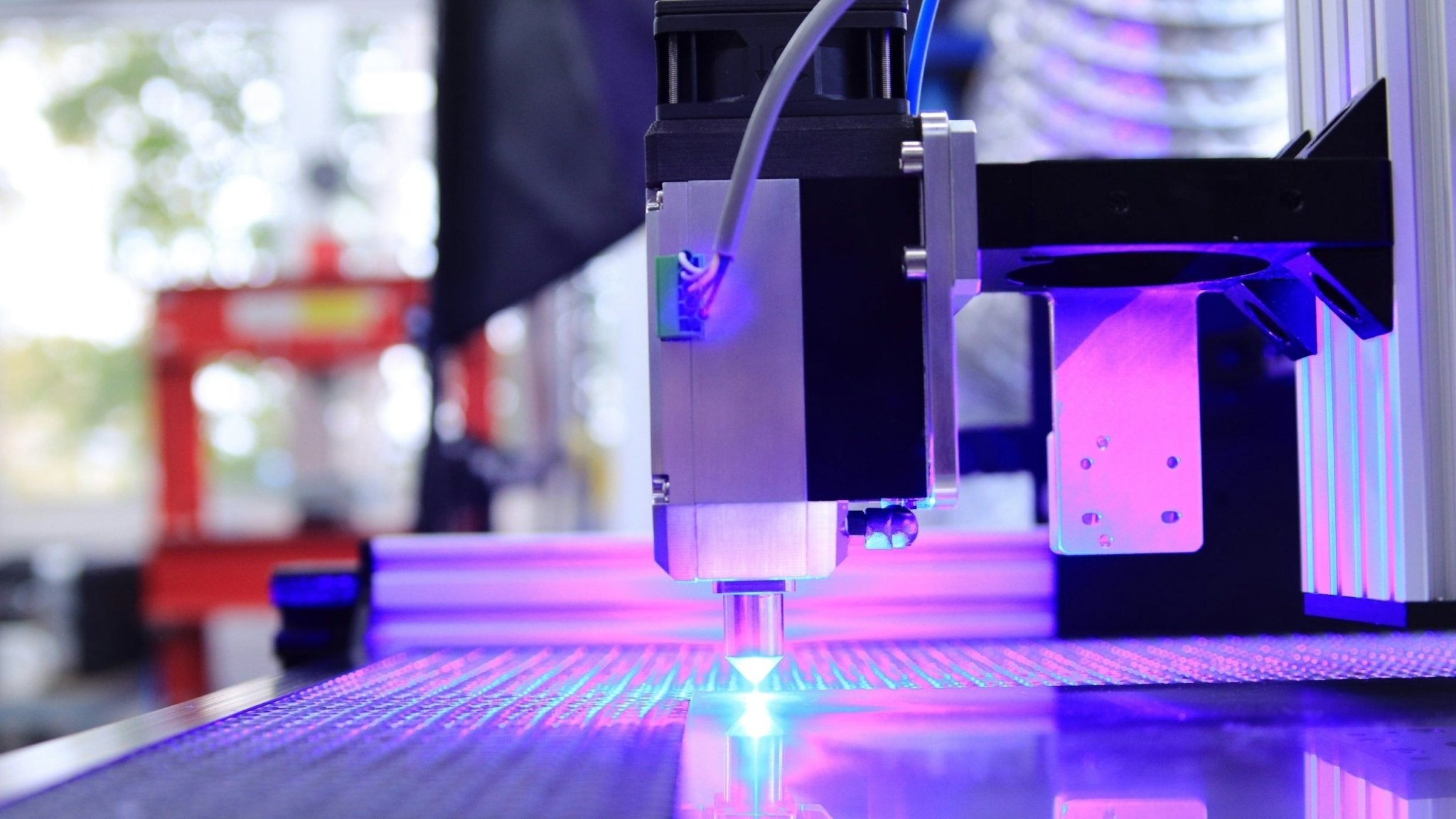

Did you try using your new laser engraver, but you were disappointed with the results? This might be because you didn’t know about these expert tips.

There are a couple of things you need to know when you are a beginner engraver. Just because you have the best laser machine, it doesn’t mean that the quality will be automatically perfect. These are tips on how you can achieve perfect laser engraving results, every time.

Are laser engravers hard to use?

Firstly, a common question that we are getting regularly. Are laser engravers hard to use? Most of the time, the answer will be no. However, there are different types of engravers. Some are harder to use than others. Especially when it comes to the larger, industrial engravers.

If you are new to laser engraving, it is recommended that you purchase an engraver that will be suitable for new users. Practice makes perfect, so practice on scrap material to get familiar with the engraver.

Expert tips for achieving the best engraving results

Do you want to have laser engraving results that look professional? Then you might want to know more about these expert tips. With understanding these tips, you will be successful faster.

Adjust the laser power, speed, and frequency according to your materials

To be successful with your laser engraving machine, you need to understand the settings of your power, speed, and frequency.

- Laser power. The higher the power, the deeper the image will burn into the material. This can also cause damage to the material if the power is too high for the thickness of your material.

- Speed of the laser. You don’t want to set the speed on the fastest setting. The slower the speed, the more detail the image will have. Faster settings are for less detailed work, and mass-production.

-

Laser frequency. Something, not many people understand. On wood or acrylics, you might want to use a lower frequency than with metals.

Understanding DPI

DPI stands for Dots Per Inch. This is basically the resolution of your engraving. A higher DPI will result in more detail. It is similar to photos you take with your smartphone. The higher the resolutions the better quality the photo will be.

For high detail, you want to consider between 300 and 600DPI. This is ideal for logos with finer details. Standard detail should be between 100 and 200DPI. This is suitable for text and larger graphics where there aren’t fine details.

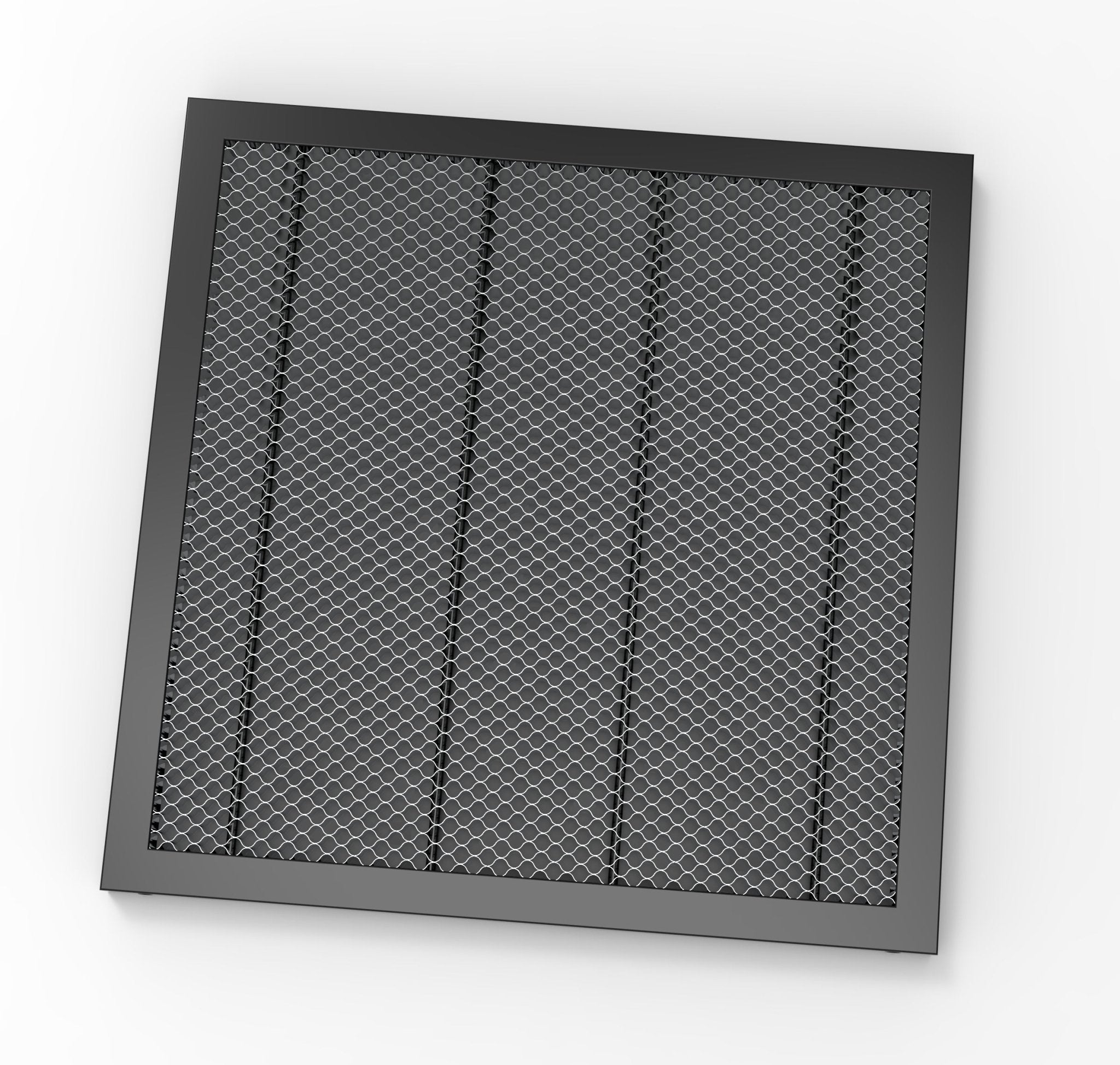

Consider air assist

Another important tip is to make use of air assist. This is if you have a laser engraver that has this feature. Many have this feature, but they aren’t using it. The main reason why this is something to use is to reduce smoke and fumes while engraving.

This is also important to use when using a laser cutter machine as well. It is also important for keeping the engraving area cool. It will improve the quality of the engraving.

The file format for engraving

You might not have known this before. The file format for engraving should be a vector file and not something like SVG or DXF format.

The vector format ensures smoother lines and curves, which will be much better for detailed engraving.

Other tips to consider for laser engraving

Now that you know the engraving tips from an expert, you also need to know these tips. These are general tips that every laser engraver needs to know. This will make engraving so much easier and look more professional.

Understand your materials

Yes, different materials can be used for engraving. However, some materials are just working better than others. It is also important to know which material will be better for which project. These are the four materials and things to consider about them:

-

If you are considering engraving on acrylics, you might want to consider cast acrylics over extruded acrylics.

-

Something to consider is that hardwood engrave better than softwoods and have higher quality results.

-

For metal engraving, you need to consider using a fiber laser or a CO2 laser with a special coating, Metal can damage an engraver easily.

Test and calibrate the settings before engraving

For you, this might sound like a waste of time and materials. However, if you want to make sure that you will get the best results, this is an important step that you should not forget. When you are testing and calibrating the engraver, you will have much better results with your final product.

The thickness of the material needs to be considered

People forget to consider the thickness of the material that is engraved. Thicker material would require multiple passes at lower power. With materials like metal, thinner might be best for engraving projects.

Conclusion

Because engraving materials are expensive, we don’t want to waste any materials with low-quality engraving. And, engraving can be hard if you are doing this for the first time. This is why knowing these expert tips is so important. It will make it easier to succeed with your engraving project. Even if this is your very first engraving project. Just remember that every engraver is different, so you might want to practice scrap materials before you start working on your projects.

In the end, i wanna share this video to you: Top 12 Tips For Laser Engraving The Best Image on Wood. From optimizing engraving settings to mastering design tricks, this video covers everything you need to know. If you’re passionate about wood engraving, you’ll love this video—it’s loaded with practical advice and step-by-step techniques.