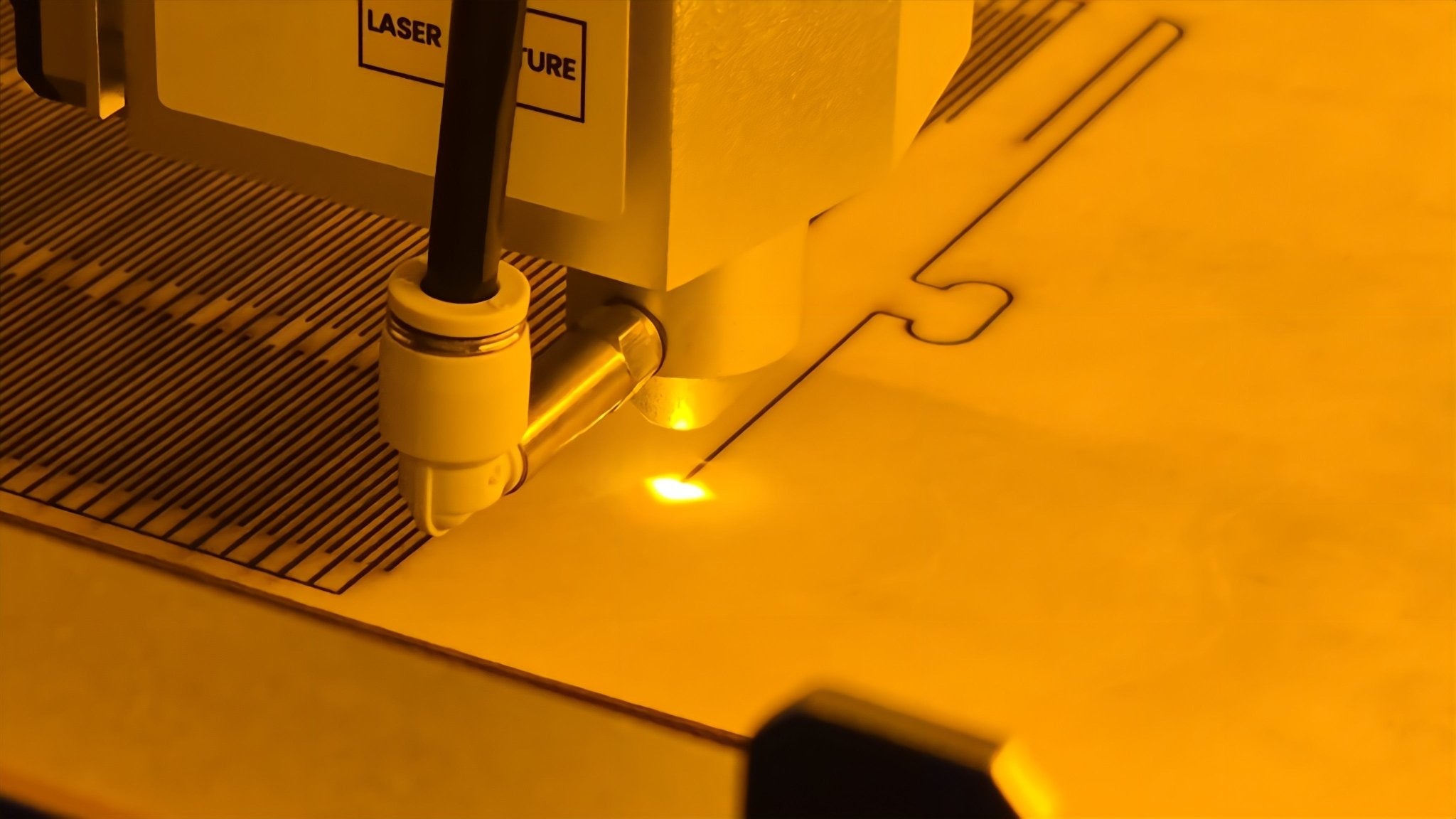

Before you can purchase a laser engraver and cutter, there are a couple of things you need to consider first. The first thing to consider is the materials you need to cut. Some materials can be cut with any engraver. However, there are materials that you should never use, because of serious endangerments. It is important to read and remember these guidelines for choosing the right material for your laser engraver. Then you will know for sure that you won’t damage your engraver in any way.

Different laser engravers use different materials

This is really important to know. Different laser engravers use different materials. Most engravers and cutters can be used on these materials:

-

Wood

-

Paper

-

Cork

-

Certain plastics

You need to take your time when searching for a material to engrave on, with your new laser engraver. Or, if you have the material and need to purchase the engraver, you need to consider what engraver would be best. Some engravers can just cut through basic materials that are thin. Stone, marble, and glass need a special engraver. This is so that the material doesn’t break when it is engraved on, or cut.

Basic materials that TOOCAA engravers can use

We already looked at the basic material that all engravers can use safely. It includes wood, paper, cork, etc. This is more detailed information about each material you can use on an engraver like Toocaa.

Wood

Wood is one of the more popular materials for laser engraving and cutting. Wood normally comes in different types and colors and using a laser cutter can create different designs. Most laser engravers and cutters can be used with wood.

The only thing that you need to consider, is the different types of wood. The softer wood creates a better project than harder wood. Soft wood includes pine and spruce.

Acrylic

Besides wood, acrylic is the most common material to use for engraving and cutting. There are a large variety of different colors and thicknesses to choose from. Each thickness creates a different finished look. The only thing to consider here is that you might want to consider a smooth and even surface for engraving. Avoid acrylics that have air bubbles or any other irregularities that might ruin your engraving project.

Leather

Most leather products that you see in stores have been made by an engraver and cutter. There aren’t many options to design signs and pictures on leather. Leather isn’t the most common engraving material, because of its difficulty in creating perfect designs and patterns.

You should make sure that your engraver can make use of leather for engraving. Don’t just start using the leather and think that your engraver will be compatible. It isn’t always the case.

Normal glass

Normal glass is easy to engrave on. And, most high-quality laser engravers can use this material for the most delicate engraving. Because there are different types of glass, you need to purchase the glass that is designed and manufactured for laser engraving.

Glass is fragile and can break easily if you are using the wrong laser for engraving. You should also remember to avoid glass that has different coatings on, or that are colored. These materials can ruin your finished look.

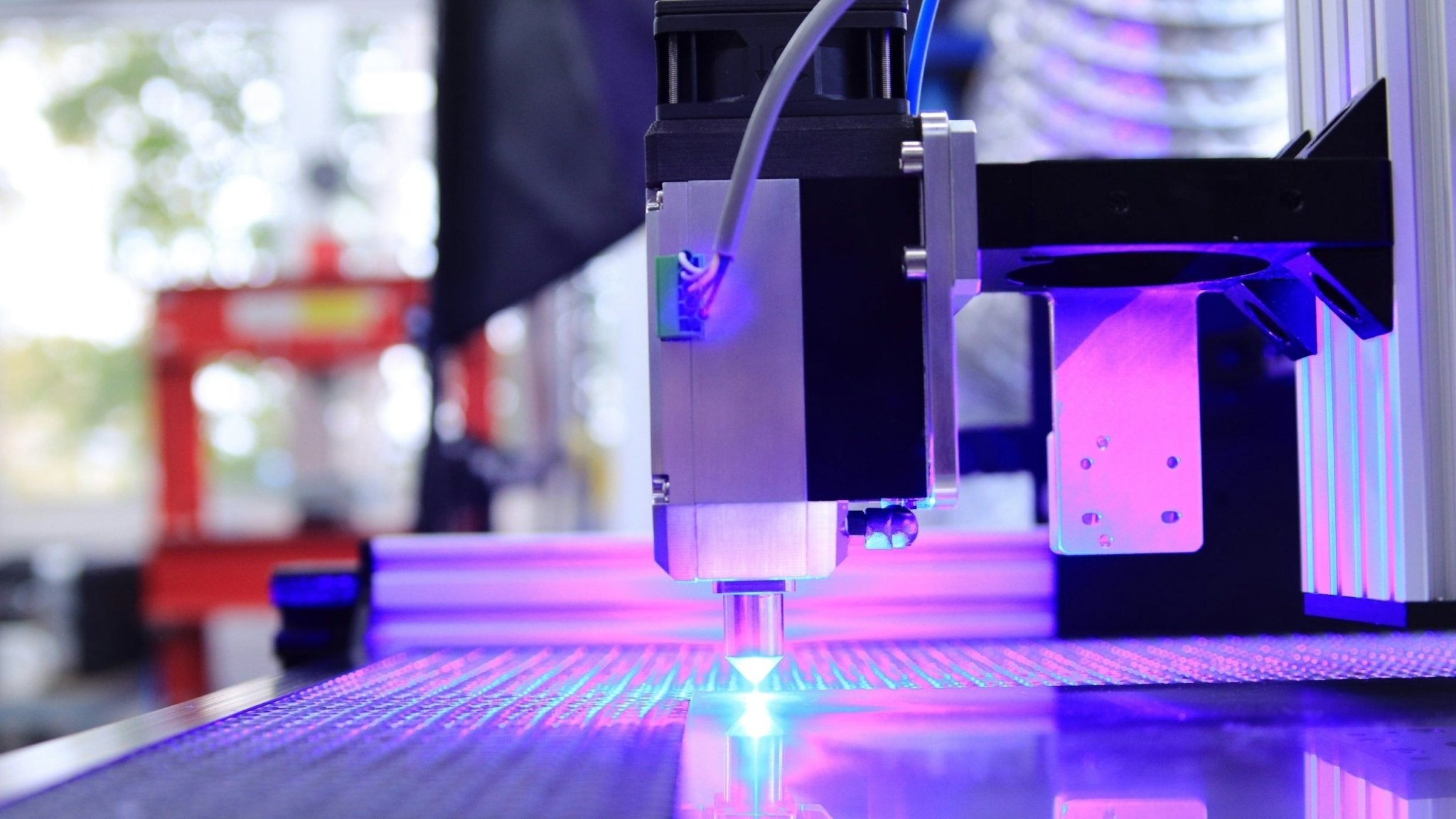

Never use these materials on any laser engraver

You should never just use any materials without researching them. Some materials are extremely dangerous to engrave and cut with a laser. It can leave harmful fumes or can even catch fire. These are some of the materials that you should never use on any type of laser engraver.

-

PVC materials. It gives a dangerous gas, chlorine gas when it is getting cut.

-

Thick Polycarbonate and Lexan. It can catch fire

-

ABS materials. It can cause cyanide gas and it can melt

-

Milk bottle plastic and similar HDPE plastics. It will catch fire

-

Polystyrene foam. It will catch fire

Conclusion

It doesn’t matter if you have the laser engraver or if you have the material for your project. You need to make sure that you have the right material at hand. Too many accidents were reported, this year only, because of using the wrong materials on your laser cutter.

The best thing you can do is to research as many times as possible to ensure you have the right information to decide which engraver will be a great fit for your product and material.

I'm happy to recommend this video to you. Whether you are a beginner or a professional, this video can add some inspiration to your creativity. Let's take a look at what interesting things Rob has made!