Yes, this can happen a lot. Especially beginner laser engraver users. Overheating and melting surfaces can be devastating. It can cause malfunction of the machine and damage to your material. There are a couple of things that you can do that will ensure that you decrease the chance of overheating and melt your laser projects.

These are some of the most important things to know when you are struggling with overheating and melted products.

Are overheating and melting happening a lot

A question that we are getting a lot from new laser cutting users. Are overheating and melting happening a lot? And, how can you prevent it from happening?

Under normal use, it isn’t supposed to overheat and cause melted projects. When this happens, you might have done something wrong or used the wrong materials. Low-quality engraving and cutting machines are also more prone to overheat. The good news is that there are ways how you can limit this problem.

Ways on how you can avoid overheating and melting during laser cutting and engraving

When this is something, you are having problems with, then you might need to know how to locate and eliminate the problem of overheating. The more you know about the risks of melting and overheating, the easier it will be to repair.

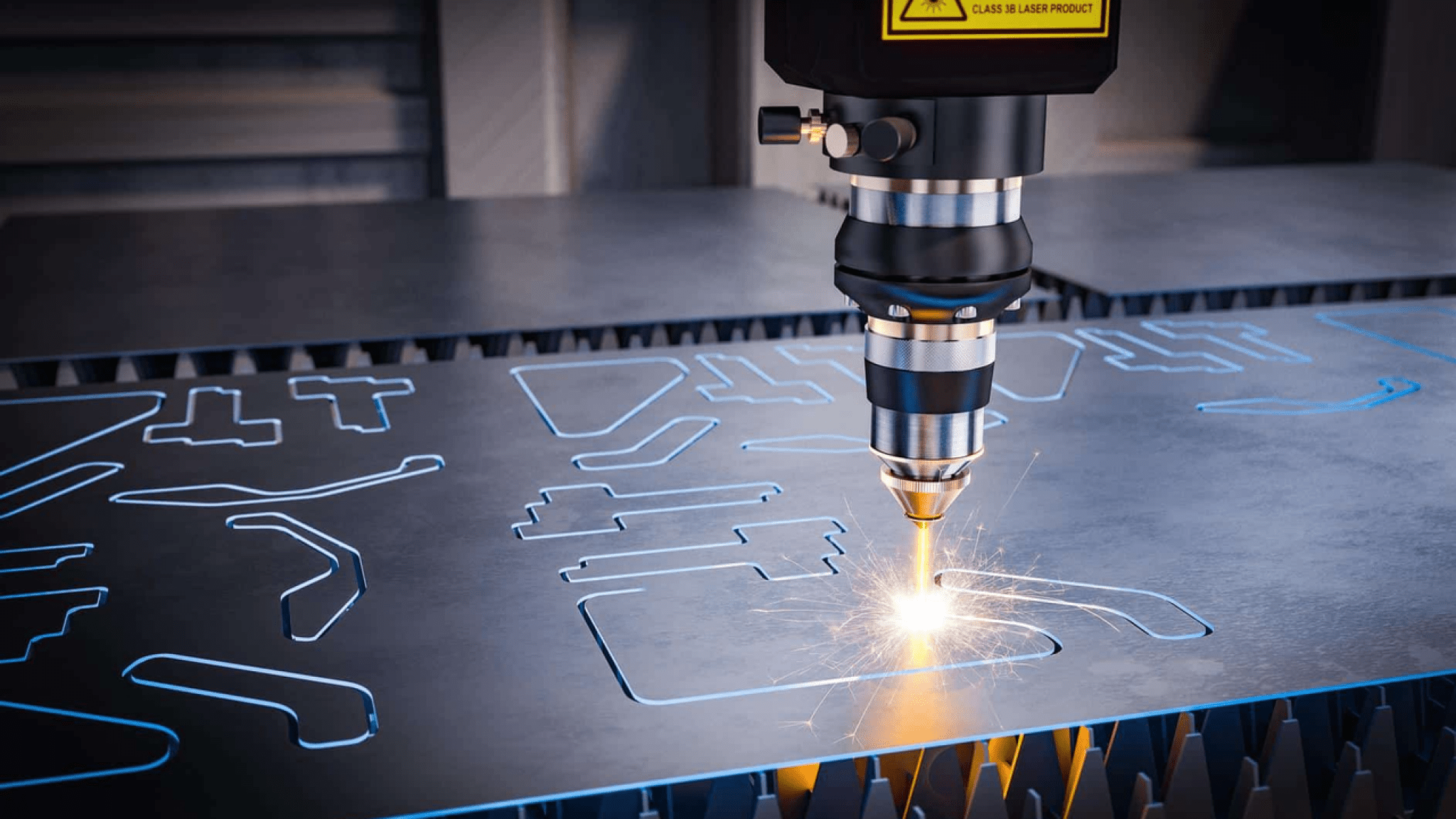

Choosing the right material

This is the most frequent culprit of overheating. Choosing cheaper material, or doesn’t have the right thickness for your project can cause overheating. Knowing exactly what type of materials your laser cutting machine can use, will lower the risks of overheating.

Different machines are compatible with different materials. And, some materials are not recommended to be engraved or laser cut on. Some of these materials will include:

· Epoxy resins or polyepoxides

· PVC also known as polyvinyl chloride

· Milk bottle plastic or HDPE

· Any glued materials.

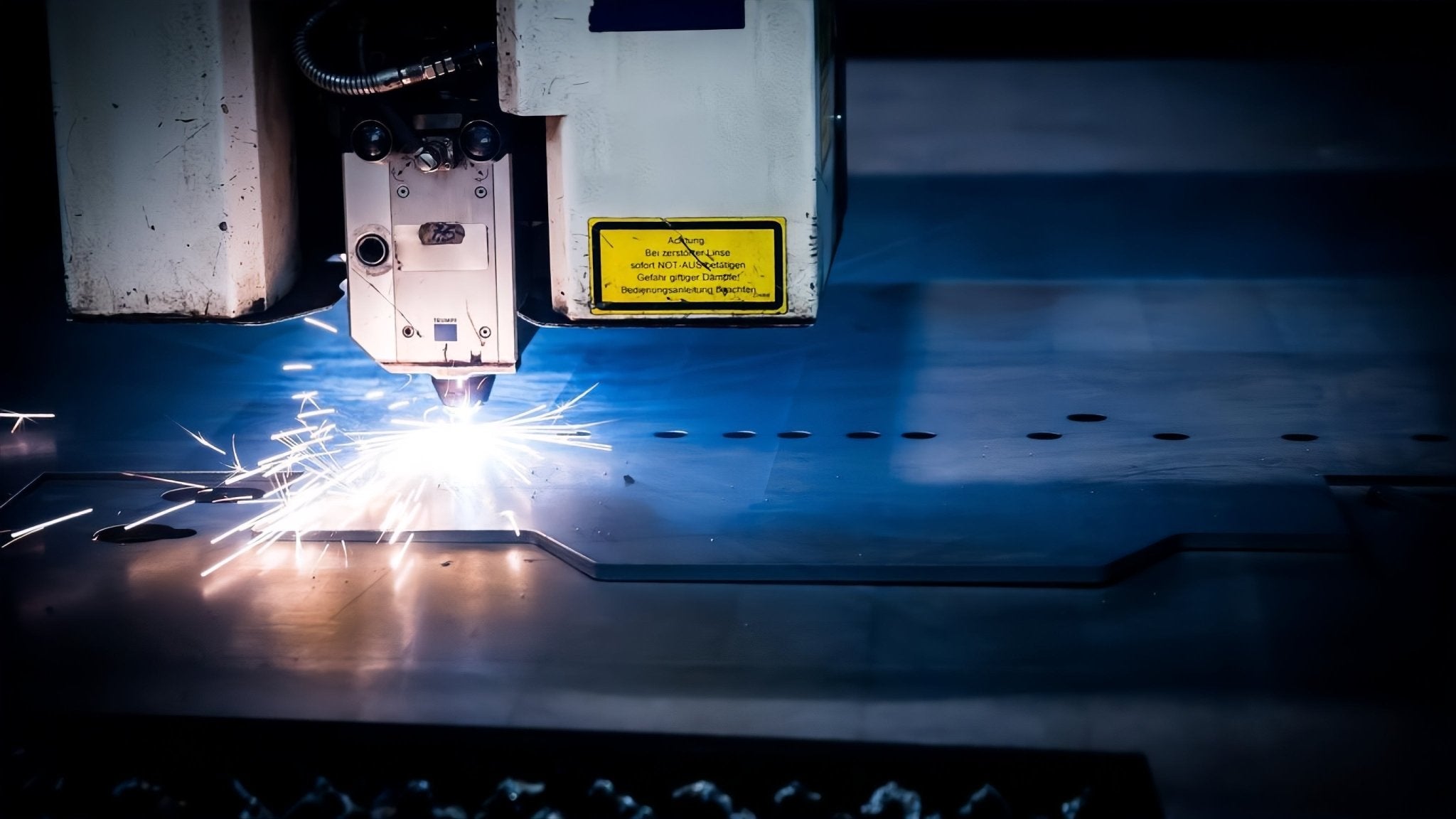

The right laser power and speed are essential.

Another culprit for overheating is using the wrong power and speed for the material and the thickness of the material. It is important to adjust the power and speed according to the materials. The higher the power, the better the chance of having overheated materials. This can lead to burn, melting, or even warping materials.

Speed also needs consideration. The slower the laser goes, the less chance there is for overheating. If you aren’t sure about the right speed, then remember this. The thicker the material, the lower the speed should be.

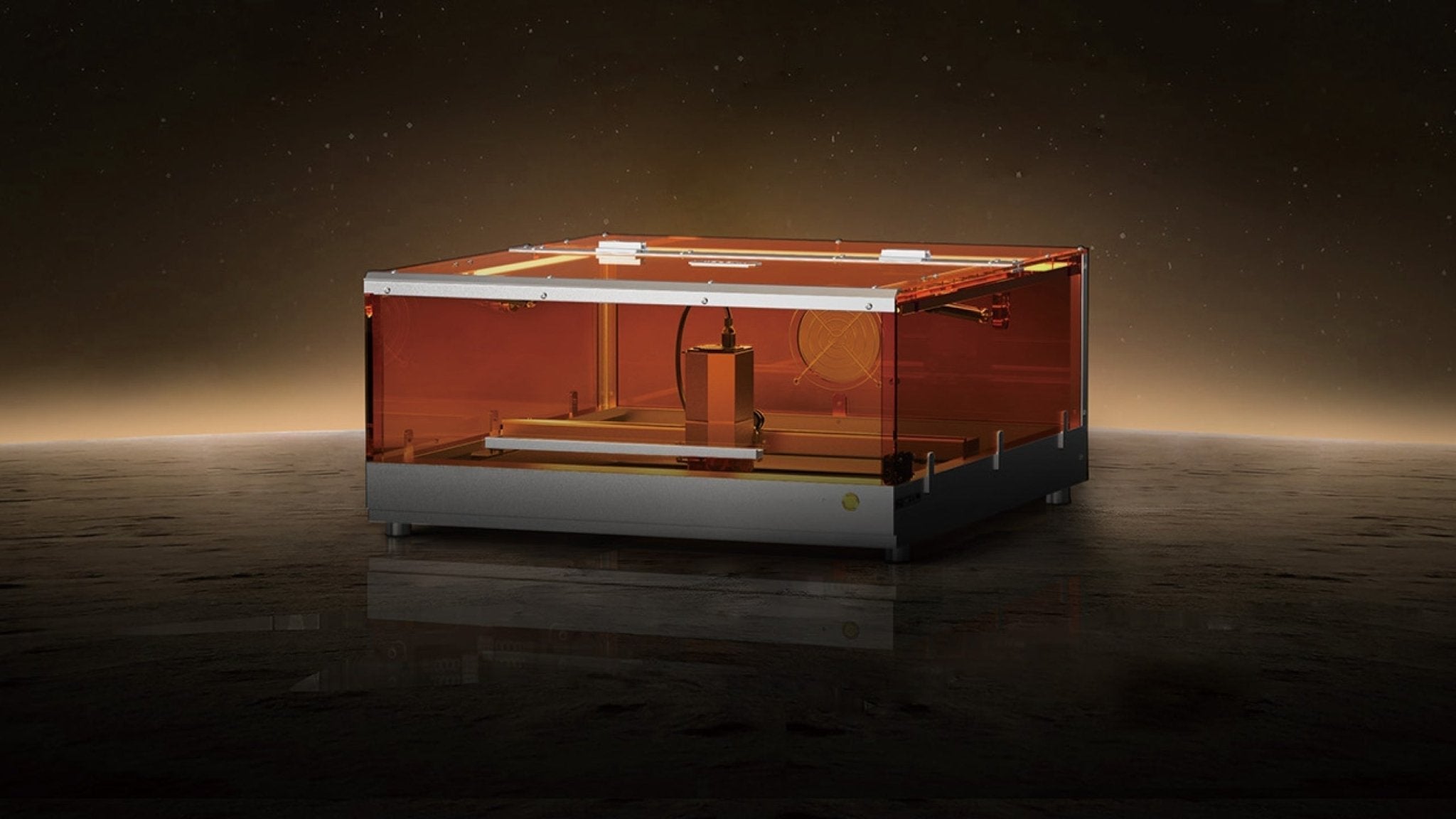

Air assist or cooling system installation

Some high-quality laser machines come with a cooling system or air assist system installed. However, this isn’t installed in the lower-cost engravers.

If you have a machine with this feature, then there is nothing to worry about. However, those that don’t have these systems installed should consider adding one. An air assist feature is a system that blows cold air onto the cutting area. Cooling the process down. This lowers the risk of overheating and melting.

Heat-resistant materials

Don’t ever use materials that aren’t heat-resistant. These are materials that aren’t recommended for engraving. Materials that are too thin, or that aren’t heat resistant always have a better chance of becoming overheated and melting.

Talk to a professional if you are still unsure if your material is safe for laser cutting and engraving. It is also recommended to double-check the thickness of the material.

Fumes increase heat and lead to overheating. Work in a well-ventilated area

You might also want to check the amount of ventilation the machine is installed in. The more ventilated the room, the less heat there will be. Fumes increase the heat of a room. And, this can cause health hazards for you, and overheating and melting problems on the machine.

You need to consider the size of the engraver and the available size for installing it. If this is a tight fit, you might want to consider another, smaller engraver.

Monitoring the process at all times

You can prevent overheating and melting from happening in the first place. You just need to monitor the complete process. If you see the temperature on your machine is increasing you can pause the work until it has cooled off.

By monitoring the process, you will also be able to see how long you can work with certain materials before the laser gets too hot. Making it easier to decide how long you need to rest the machine after each use.

Conclusion

If you think that overheating and melting is just part of the engraving process, then you need to think again. There are many reasons why this can happen. Not only can this cause damage to the machine, but it can start a fire because of all the heat. Causing structural damage as well.

With all this information given, it is easier to engrave or cut with a laser without damaging your materials and your machine. These laser machines are expensive and you don’t want to replace one, because of overheating.

I'm glad to share this video to you: Laser Hack: How to get perfect Acrylic Cutting Results by Using Wet Paper Towels. This video introduced a effective trick which can minimize flare-ups during acrylic cutting. Follow this video, have a try on your own work, then you may get a edge clear arcylic work without overheating.