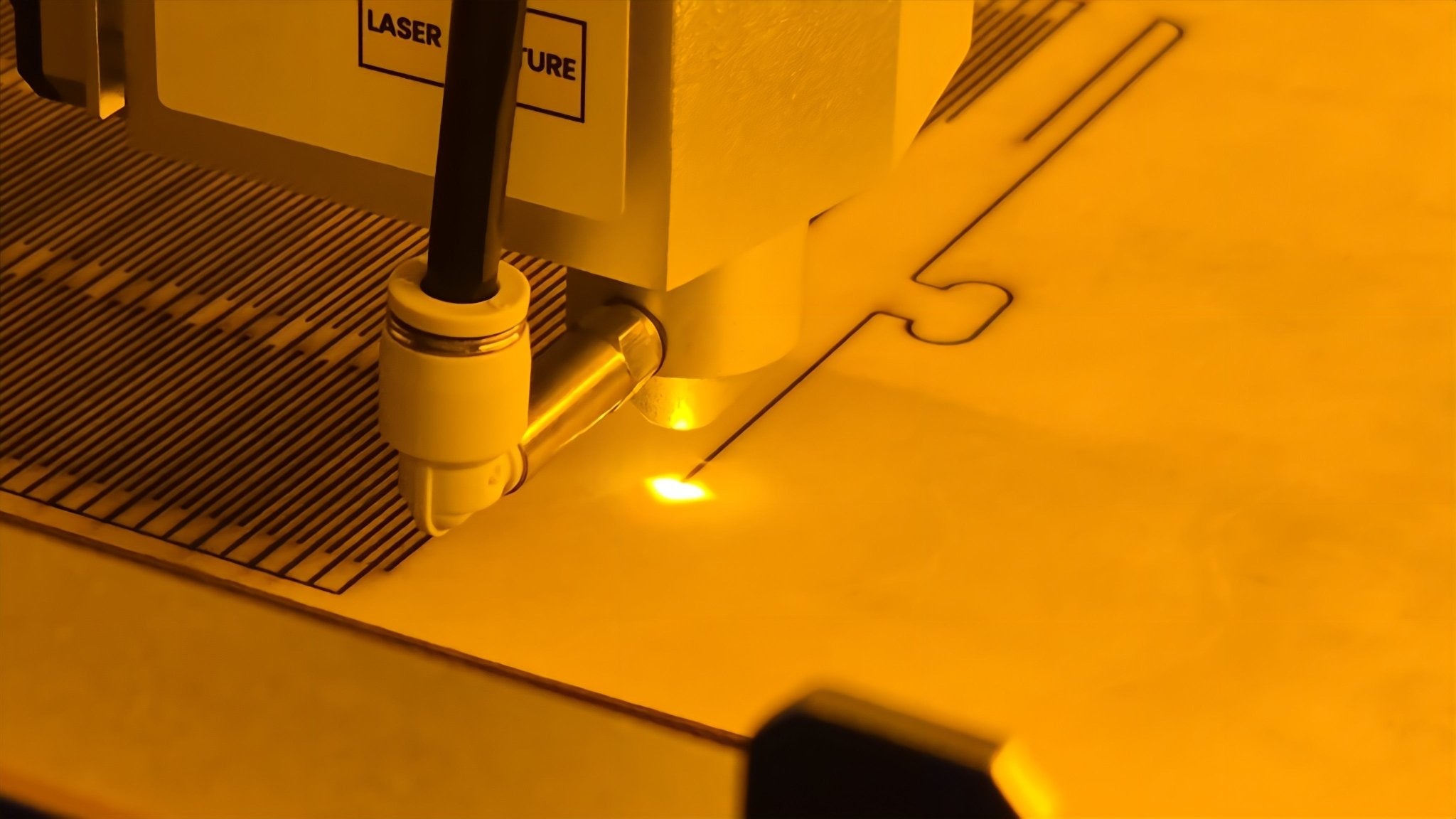

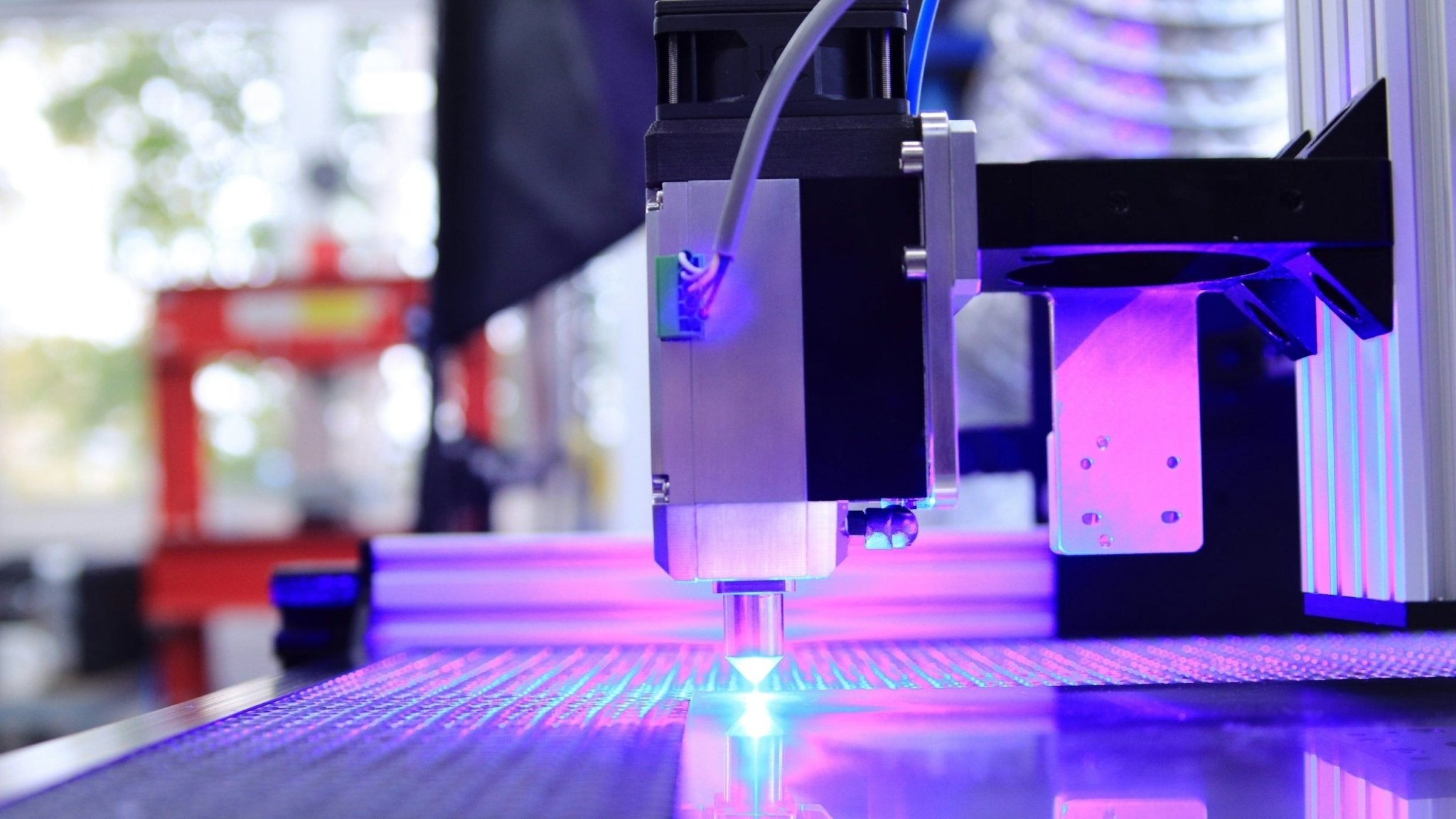

Laser cutting and engraving machines are great tools for a small business. The machine can give you many years of working if you take care of it correctly.

There are a couple of things you need to know about the maintenance of a laser cutter. To make sure that you can work with the machine for a lot of years to come. The key here is to do regular maintenance and to make sure that you consider preventative maintenance over just doing repairs. These are everything you need to know about maintaining your laser cutter for optimal performance and to enjoy a working cutter for years to come.

Why laser cutter maintenance is important

These laser cutters are expensive and repairing them once they break, is just as expensive. This is why you need to make sure that you do regular maintenance. You should not wait until a part on the cutter breaks before you consider repairs. These are just some of the reasons why you need to consider regular maintenance.

-

Run in optimal performance. This is the most important benefit of regular maintenance. The machine will run smoothly as it is still a new machine. With optimum cutting speed and efficiency.

-

It will ensure a prolonged lifespan. The moment that the laser cutter is maintained regularly, it will give you years of perfect cuttings. You will not have to worry about replacing the cutter for years to come.

-

Prevent accidents and injuries. Using a cutter can be dangerous if the user isn’t working the machine correctly. However, injury and accidents are also higher with a machine that isn’t maintained. With more maintenance, the machine will not break down, causing injuries to yourself or your workers.

Guide to the correct maintenance plan for any laser cutters

When you are doing the right maintenance, you will have a maintenance schedule for every morning, each week, and monthly checks. This is the best way to ensure that your laser machine is always in optimal condition.

Daily maintenance before using the laser cutter

A good laser cutter operator does daily maintenance before cutting. This is to make sure that there is nothing broken, or starting to fail while cutting. When the machine fails during operation, it can cause serious damage to equipment and the person handling the machine. These are daily checks that need to be done before the workday starts.

-

Check for loose bolts, screws, and all electrical connections. These are things that can happen during frequent use during the day.

-

Checking the alignment and focus of the laser is something every laser handler needs to do before use. If the alignment is incorrect, it can cause injury, but also sub-standard cutting.

-

Taking the time to double-check the calibration which includes power, speed, and focus point.

-

One of the most important things you need to check is the coolant levels. If the coolant in the machine runs out, you will damage your machine and repairs will be expensive.

Weekly maintenance for regularly used laser cutters

Besides the daily maintenance, there should be a schedule for weekly maintenance of the laser cutter as well. There are parts of the cutter that can fail over time, that need to be checked regularly. You don’t need to do these checks daily but weekly is recommended.

-

You might want to check and inspect the laser mirrors and lens. This is for any dirt or damage on the laser mirror and lens. To work precisely, these parts need to be in perfect condition.

-

Laser output can also change over time. The output needs to be monitored so that it can stay according to the manufacturer’s specifications.

-

Check and clean the air filter. You will be surprised at how much dirt the air filter can gather in a week. To ensure perfect working conditions for the cutter, the air filter needs to be clean.

Monthly maintenance on your regular used cutter

Monthly maintenance on the laser cutter is for those parts that don’t break easily. But that can break during wear and tear. Scheduling monthly maintenance on these will ensure a cutter that will last for years to come. This maintenance should be done monthly:

-

Checking and changing the cooling water for the water chiller. This is essential to keep the subject cool during the laser cut. Without it, the machine can overheat and break.

-

Another thing that needs monthly checks is the exhaust system. During laser cutting, the machine produces fumes and smoke. The exhaust system removes these fumes. Without regular maintenance on the exhaust system, the cutter will overheat, and it can lead to dangerous working conditions.

Conclusion

One thing we will agree on is that a laser cutter is expensive, and you can’t just replace a broken cutter. This is why regular maintenance should be done. We are discussing daily, weekly, and monthly maintenance checks. To ensure that no matter how much you are using the laser cutter, it will stay in perfect condition.

I am very pleasure to recommend this useful video in which Cool Tools and Ian Charnes present 4 Tips for better, safer laser cutting in detail, including how to get the best engraving results, how to solve the problem of fire accidentally, etc. I hope it can help you.