In recent years, with the development of desktop laser cutting machines, diversified requirements such as cutting thickness, working area, engraving speed, etc. have been improved. Besides choosing a laser cutting machine based on its operational characteristics, safety features have become a critical consideration for many users. This concern often guides the decision-making process, with the choice between open frame and enclosed laser cutters being a key differentiating factor.

What is Open Frame Laser?

Open frame laser cutters are generally more accessible and allow for easier observation of the cutting process, making them suitable for environments that require flexible adjustments and monitoring. However, they offer lower safety levels and require extra caution from the user.

- Pros:

Increased Visibility:The design is usually simpler, allowing users to directly observe the cutting or engraving process, facilitating immediate adjustments.

Ease of Access: Simplifies the placement and removal of materials. Easier to handle large or irregularly shaped materials due to the lack of enclosed space.

Cost Efficiency: Generally cheaper than Enclosed Lasers.

- Cons:

Safety Hazards: Higher exposure to the laser beamscan pose risks if safety protocols are not strictly followed. Users need to take additional safety measures, such as wearing protective glasses and ensuring proper ventilation of the work area.

Environmental Impact: The laser and materials are more susceptible to the surrounding environment, potentially affecting their operation.

Noise Concerns: Typically noisier, which may be a consideration in noise-sensitive environments.

Who Benefits from Open Frame Lasers?

Open frame lasers offer unique advantages for specific applications. These lasers are ideal for projects requiring larger or irregularly shaped materials, providing greater accessibility and adaptability. In environments where precision and customization are crucial, such as advanced workshops, large art installations, and research settings, users often find that open frame lasers effectively meet their needs.

What is Enclosed Laser?

Enclosed lasers are particularly suitable for environments where safety and ease of use are paramount. They are an ideal choice for educational institutions, hobbyists, and small businesses that prioritize user safety and regulatory compliance. These lasers minimize exposure to harmful laser radiation and are designed to operate quietly and cleanly, enhancing the user experience. Schools, libraries, and community makerspaces benefit from these features, allowing users of all skill levels to safely and effectively utilize laser technology.

- Pros:

Enhanced Safety: The enclosure prevents accidental exposure to the laser and features safety interlock devices, ensuring the machine can only operate when closed.

Noise and Debris Control: Controls noise and prevents debris and fumes from escaping, thereby improving the cleanliness and safety of the workspace.

Improved Air Quality: The integrated exhaust system filters out harmful fumes and particulates, which is crucial when working with materials that emit hazardous smoke.

- Cons:

Size and Space: Enclosed systems have a larger footprint and require more space, which can be challenging in smaller workshops. The enclosed space also limits the size of materials that can be used.

Accessibility and Visibility: The enclosure may hinder access for setup and maintenance, and can reduce visibility, affecting the ability to monitor the process.

Heat Dissipation: The enclosed area can retain heat, requiring an efficient cooling system to avoid overheating.

Limited Flexibility: The design limits the size and type of materials that can be used and makes component upgrades more difficult, reducing adaptability without substantial modifications.

Who Benefits from Enclosed Lasers?

Enclosed lasers are especially appropriate for settings where safety and user-friendliness are paramount. They are perfect for educational institutions, hobbyists, and small businesses that emphasize user safety and adherence to regulations. These lasers reduce exposure to dangerous laser radiation and are built to function quietly and cleanly, improving the overall user experience. Schools, libraries, and community makerspaces take advantage of these benefits, enabling users of all skill levels to safely and effectively interact with laser technology.

Choosing the Better Laser: Enclosed Lasers vs. Open Frame

When choosing between an enclosed laser cutter and an open-frame laser cutter, it is important to consider your main needs regarding safety, space, and the type of projects you plan to undertake. Enclosed lasers are perfect for educational settings, small businesses, and situations where user safety with minimal setup is essential. Conversely, open-frame lasers are ideal for those who need flexibility and ease of use for larger projects. Each option offers distinct benefits, and your decision should be based on your particular operational requirements and environment.

Laser Classification

What is Class 1 Laser?

According to the FDA's laser classification system, Class 1 lasers are classified as the safest type of laser. They are designed so that, under normal operating conditions, they do not emit harmful levels of radiation to the user or bystanders. Typically, these lasers are completely enclosed, as the housing prevents exposure to harmful laser radiation. This aligns with why they are often preferred in environments that require stringent safety measures.

A Class 1 laser is considered to be safe under all conditions of normal use. This means that the maximum permissible exposure (MPE) cannot be exceeded when viewing the laser with the naked eye. Class 1 lasers are typically low-power lasers or have protective housing that prevents exposure to higher levels of laser radiation.

- FDA Laser Classifications

Class 1 Lasers: Considered the safest class, these lasers are completely enclosed to prevent exposure to any hazardous laser radiation. Typical power output is less than 0.4 µW, making them incapable of producing harmful radiation under normal operating conditions. Examples include some types of laser printers and CD/DVD players.

Class 2 Lasers: These emit visible light only, with a power output of up to 1mW. They are considered safe because the natural blink reflex will protect the eye in the event of accidental exposure. Commonly used in classroom laser pointers or aiming devices.

Class 3R Lasers: Have a slightly higher risk, emitting power between 1mW and 5mW. While not hazardous for brief unintentional exposure, they can be dangerous if viewed directly with optical instruments. Usage includes consumer laser levels and gun sights.

Class 3B Lasers: Direct exposure to these lasers can result in eye injury, with power outputs ranging from 5mW to 500mW. These require safety measures like protective eyewear and restricted access during operation. Applications include scientific and medical lasers.

Class 4 Lasers: The highest and most dangerous class, with outputs exceeding 500mW. They can cause skin burns, eye damage, and even ignite combustible materials. Extensive safety controls are necessary, such as emission indicators, beam stop or attenuator, and safety training for users.Typical uses include laser cutting, welding, and other industrial applications.

necessary, such as emission indicators, beam stop or attenuator, and safety training for users.Typical uses include laser cutting, welding, and other industrial applications.

This classification helps users understand the level of precautions required for different lasers and why Class 1 is the ideal choice for a safer, more controlled environment.

Why Choose Class 1 laser Laser?

Class 1 lasers are completely enclosed, eliminating any risk of exposure to harmful radiation and meeting the highest standards of laser safety. TOOCAA falls into the Class 1 laser category, providing maximum user protection. This classification is particularly crucial in settings where safety is a top concern, such as educational institutions, shared workspaces, and areas frequently accessed by non-specialists.

The built-in safety of Class 1 lasers not only prevents accidental exposure but also eases regulatory compliance, reducing the need for extensive safety training and protective gear. TOOCAA dependable safety features make it perfect for widespread adoption of laser technology in environments where ensuring user safety is essential.

Safety Guidelines and Procedures

Routine Maintenance

Perform regular inspections and maintenance on your TOOCAA laser cutting machine to ensure that all safety mechanisms are functioning properly. Keep the cutting machine clean to prevent any buildup and regularly check for potential faults or damage that could pose a safety risk.

The TOOCAA Help Center provides user guides and videos tutorials for each model of TOOCAA laser. These detailed introductions will help keep your laser cutting machine in top condition and maintain safety standards.

After-Use Cleaning

After completing each laser cutting project, it is crucial to thoroughly remove all dust from the workspace. Regular cleaning not only minimizes the risk of fire caused by combustible materials left in the area but also ensures that air quality is maintained, protecting you from potentially harmful fumes and particles. This practice enhances the safety of the working environment and keeps the equipment free from obstructive debris, thereby extending the lifespan of the machine.

Ensure Ventilation

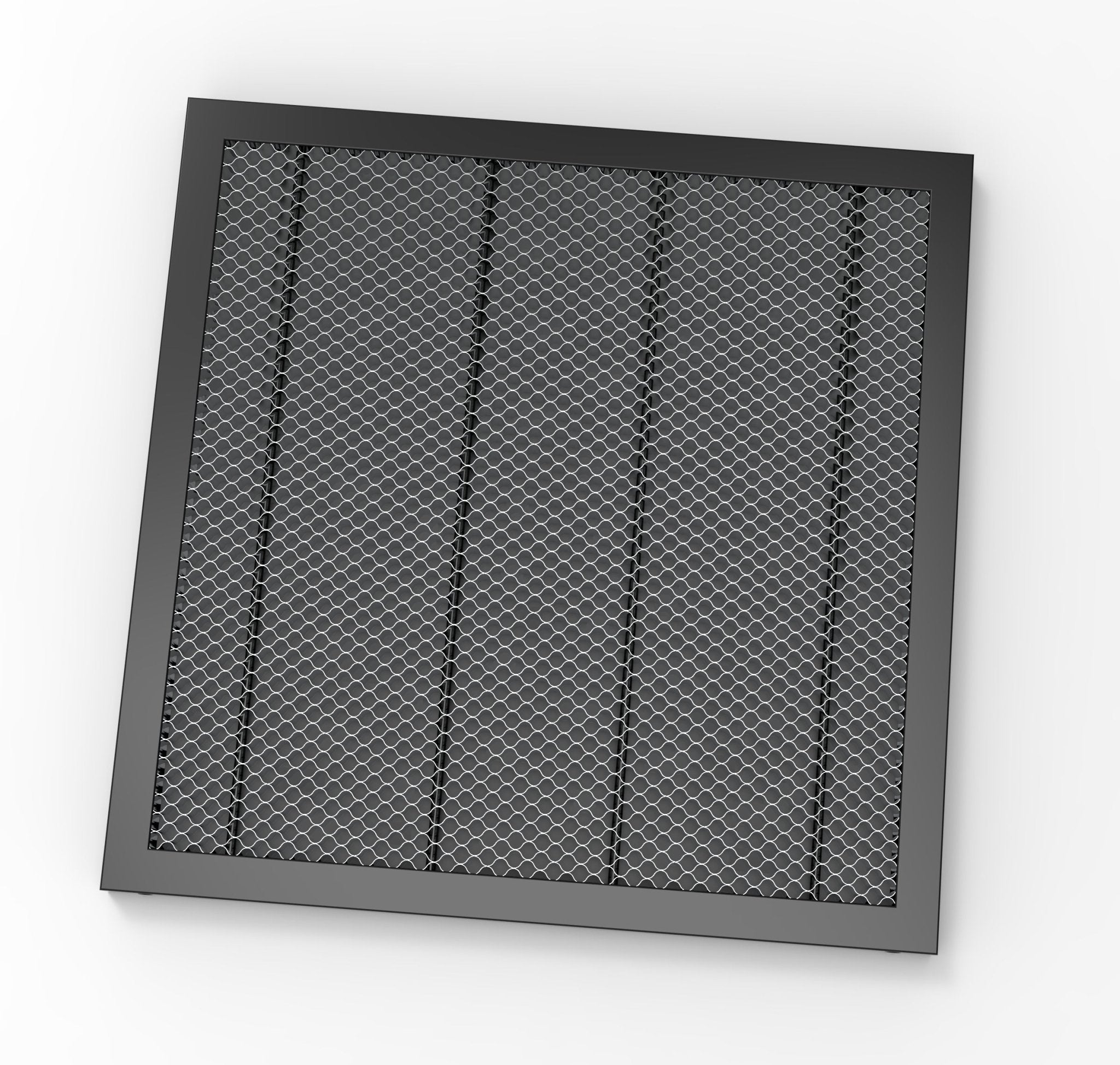

Lasers can produce fumes and smoke during operation, necessitating an effective ventilation system to purify the air before it circulates back into the room. The TOOCAA L2 is designed specifically for this purpose, featuring a three-stage filtration system, filtering effect up to 0.3μm 99.97% that significantly improves the air quality in your workspace.

→ Check Out TOOCAA Smoke Purifier

The Best Choice for Enclosed Diode Lasers-TOOCAA L2

The TOOCAA L2 laser cutting machine not only has six safety badges such as flame detector, gyroscope detector, and USB safety interlock protection, but the laser head is designed with a snap-type quick-release structure, and it is also a Class 1 diode laser cutting machine.

The TOOCAA L2 adopts an enclosed design, the smart enclosure adopts a fully transparent design with fashionable and bright colors, effectively isolating light pollution, smoke, and dust and making no noise.

In addition, it includes an emergency button that can immediately cut off the power supply, thereby increasing safety in emergency situations.

These features make the TOOCAA L2 ideal for educational environments and shared workspaces, emphasizing its position as one of the safest diode laser-cutting machines on the market.

→ Got it! -- Expert of safe engraving

→ Got it! -- Expert of safe engraving