With the continuous advancement of technology, laser engraving has evolved from a complex industrial process to a fine art widely used in personal and commercial fields. The TOOCAA L2 laser engraving machine leads the technological innovation in this field with its excellent performance and innovative safety features. This article will explore the operating principles, material interactions, process flow, and how to effectively master this advanced technology of the TOOCAA L2.

Operation principle and technical advantages of TOOCAA L2 laser engraving machine

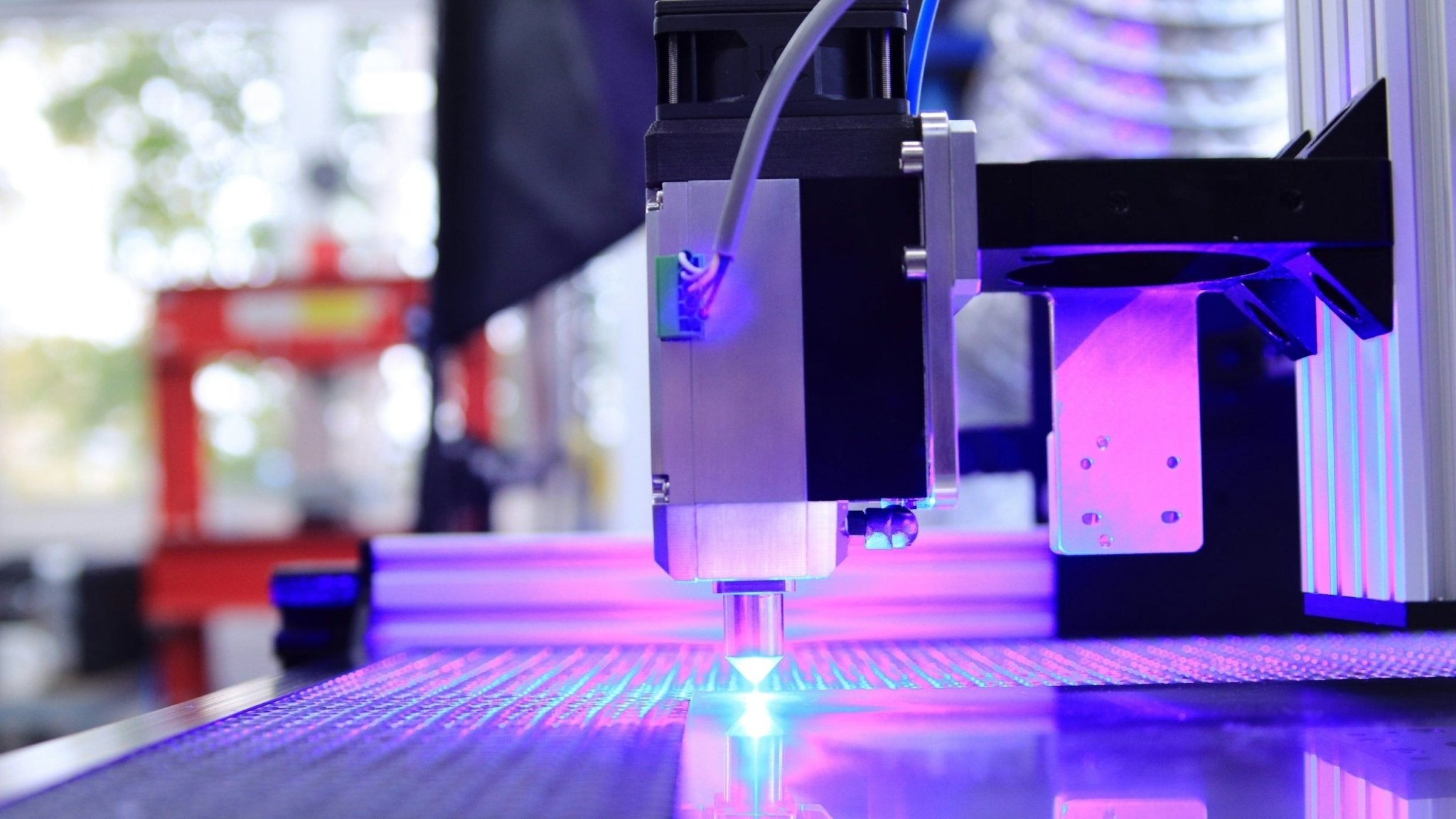

The core of the TOOCAA L2 laser engraving machine is its sophisticated laser system, which can generate highly focused beams and achieve fine processing of the material surface through precise control of energy output. The basic principle of laser engraving is to use the energy of the laser beam to cause physical or chemical changes on the surface of the material through thermal effects, forming durable graphic marks.

The technical advantages of the TOOCAA L2 are not only reflected in its high-precision and high-efficiency engraving capabilities, but also in its comprehensive safety feature design. It is equipped with advanced safety systems, such as an efficient smoke extraction system, flame detection technology, body tilt detection technology, and cover opening interlock technology, to ensure stable and reliable performance and operational safety in various working environments.

Material interaction and effect display of laser engraving

TOOCAA L2 laser engraving machine can process a variety of materials, including wood, plastic, acrylic, glass, stone, leather, fabric, and metal. Each material has its own unique interaction with the laser, which determines the resulting effect and texture after engraving. For example, engraving on wood produces a charred effect, while on metal it may produce oxidized discoloration or a smooth cutting surface. These different material reactions provide a wide creative space for artists and designers.

Detailed process flow and professional guidance for laser engraving

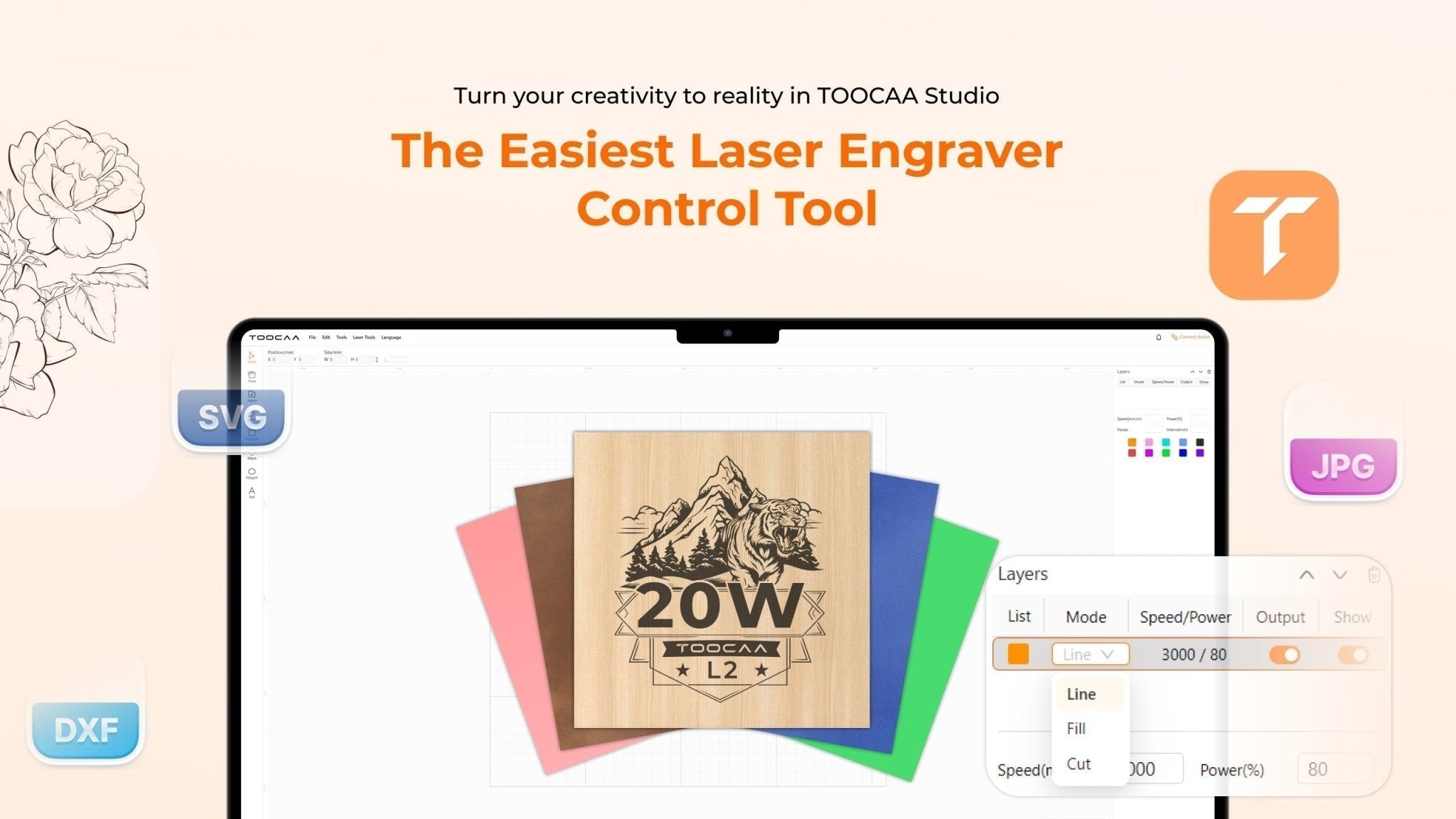

1. Design and preparation: First, use professional graphic design software to create or import the desired engraving design. For complex images, it may be necessary to convert them to bitmap or grayscale images and adjust the contrast to optimize the engraving effect.

2. Material selection and processing: Select suitable materials according to design requirements and perform appropriate pre-processing, such as cleaning and leveling, to ensure the quality of engraving.

3. Machine configuration and testing:Fix the material on the workbench of the TOOCAA L2, and adjust the laser parameters according to the material characteristics and design requirements. Conduct a small-scale test engraving to determine the optimal power and speed settings.

4. Precise engraving: Start the engraving process, and the TOOCAA L2 machine will automatically execute the predetermined engraving path. During this process, the operator can monitor the engraving progress in real time and fine-tune the parameters based on the actual situation.

5. Post-processing and completion: After the engraving is completed, the workpiece is cleaned to remove any residue, and surface treatment such as painting or glaze sealing is performed as necessary to enhance the engraving effect and durability.

High-efficiency TOOCAA L2 laser engraving machine

In order to efficiently use the TOOCAA L2 laser engraving machine, it is recommended to follow the following steps:

- Systematic learning: In-depth study of theoretical knowledge and operational skills of laser engraving, understanding the characteristics of different materials and the adjustment principles of laser parameters.

- Practice: Through practical operation of the TOOCAA L2 machine, perform various material carving exercises to gradually accumulate experience.

- Safe operation: Always follow the safety regulations for laser engraving machines, wear appropriate protective equipment, and ensure the safety of both individuals and the work environment.

- Problem solving: When encountering operational problems, promptly consult the TOOCAA L2 user manual or contact technical support to seek professional solutions.

Through the above-mentioned in-depth professional guidance, you can quickly master the operation of the TOOCAA L2 laser engraving machine and tap into its enormous potential in artistic creation and industrial manufacturing. With deepening practice, you will be able to make full use of the advanced features of the TOOCAA L2 machine to create professional-level engraving works.

Conclusion

TOOCAA L2 laser engraving machine provides an efficient and precise engraving solution for individuals and businesses, with its superior performance and safety. Whether used for industrial production or personal creation, it can meet users' needs for high-quality engraving works. With the continuous advancement of laser engraving technology, TOOCAA L2 will continue to lead the innovation and development of engraving art.