If you are doing DIY projects, you might need to purchase a laser cutter. There are different types of laser machines, and it is essential to choose the right one. With the wrong machine, you will not only waste money but also not enjoy your project making.

You don’t need to worry about finding the right laser machine anymore. We have all the information you need so that you can start your DIY projects immediately.

What can happen when you choose the wrong laser cutter?

Despite losing a lot of money when you purchase the wrong laser cutter, what other problems can you encounter? There are a couple of things that can go wrong with the wrong machine:

-

You will end up with poor-quality cutting. It can cause inaccurate cutting or you can end up with inconsistent depth.

-

The cutter you choose might not be compatible with the material you want to cut. Causing damage to your material and the cutter.

-

Safety is essential when it comes to laser cutting. With the wrong machine, you can endanger yourself and people near you.

Different features of the cutting machine

Firstly, there are a huge amount of different machine features to consider. The machine you choose will depend on the project's needs. These are some features to consider before buying your first laser cutter.

Type of laser cutter

There are different types of laser cutters. Each comes with their own features, pros and cons. The three main AItypes of lasers found on a cutter machine include:

-

CO2 lasers. Great for DIY projects. Best for non-metal materials

-

Fiber lasers. They are more suitable for metal cutting and harder materials. These machines are larger and more expensive than the CO2 lasers.

-

Diode lasers. These machines are lower-powered. Making it ideal for engraving and cutting thinner materials. Most DIY hobbyists choose this laser cutter.

Power and speed

There are three different speed options to choose from when buying a laser cutter. The low power is best for cutting thin materials like paper, thin wood, or plastic. The medium power provides a more successful cut with thicker materials that are about 6mm in thickness.

High power is designed for thick materials and metals. However, these machines are recommended for homemade DIY projects.

Safety features

If you are new to laser cutting, safety feature consideration is essential. You need to consider safety like enclosed models. This prevents exposure to the laser. Laser shields will ensure that the shield will block radiation from you and your loved ones.

One essential safety feature is the emergency stop button. Every machine needs one. This is to stop the machine immediately in case of an emergency like an injury.

Other considerations to consider

The machine features are essential, but there are some other facts to take into consideration as well. Things that can be the difference between a recommended and non-recommended laser machine.

Precision and accuracy

The best laser cutter can cut with precision and accuracy. This is why you need to look at the DPI of every machine. The higher the DPI, the finer the details will be in your engraving. DPI stands for dots per inch. Accuracy will also ensure high-quality and accurate cutting.

For more information on the precision and accuracy, you can read a variety of different reviews online.

Cooling and ventilation

Laser cutters are making use of cooling or ventilation for cutting different materials. There are two cooling methods. The one is known as water cooling. These are features that you can find on larger machines, that are cutting at extremely high temperatures.

The other method is the ventilation system. They have exhaust fans and filters. This is a safer option because they are getting rid of the harmful fumes some materials can give.

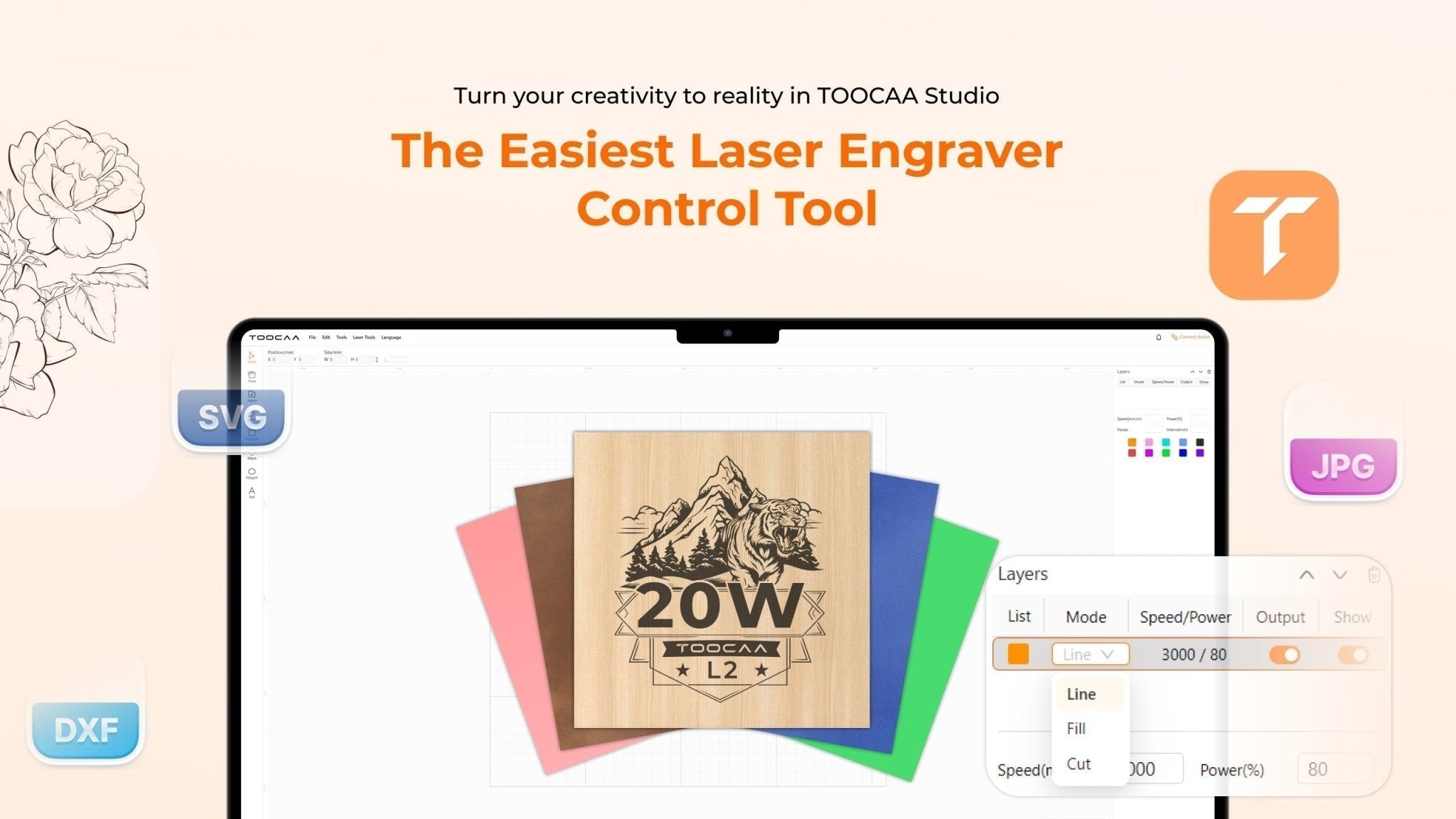

Software compatibility

Last, but not least. Software compatibility. Maybe you are working with a specific software program because you know how it works. Or, you are making a design that requires specific software. This is something to read more about before you can consider the machine to purchase.

The amount of workspace you need is also essential to consider

Many people are looking for a cutter machine or engraver. There are many of these on special, and you need to make sure that you consider the space you are working in. If you have a small room, you might need to settle for a smaller cutter. Especially if you are working with larger materials.

There are huge machines that are known as industrial machines. It will never fit into your home, and you shouldn’t even consider it. Smaller might be the best option in most cases.

There is nothing difficult in choosing the right laser cutter for your DIY project. You need to know your tools and you need to know everything is possible. With this guide, you will learn everything you need to know to find and purchase the best laser-cutting machine to create your new DIY projects.

After getting some understanding, I am happy to share this video with you. The video explains the different types of laser cutting machines, explaining their differences and the best ways to use them for different projects and needs. These include the main types of lasers such as CO2 lasers, fiber lasers, and diode lasers, each with specific properties and characteristics. The video guides viewers to choose the right laser cutter based on their repair needs and what is best.