Something that is getting quite popular is the implementation of laser engravers and cutters into a business. It is a lot easier and faster to use a laser cutter than the old, traditional way.

The only problem that many business owners have, is choosing the right machine for your business’s needs. There are different laser devices to choose from. Some are higher in quality than others. There is no reason why you should make a mistake in choosing this equipment for the first time. This ultimate guide will give you everything you need to know to buy the right engraver and cutter, the first time.

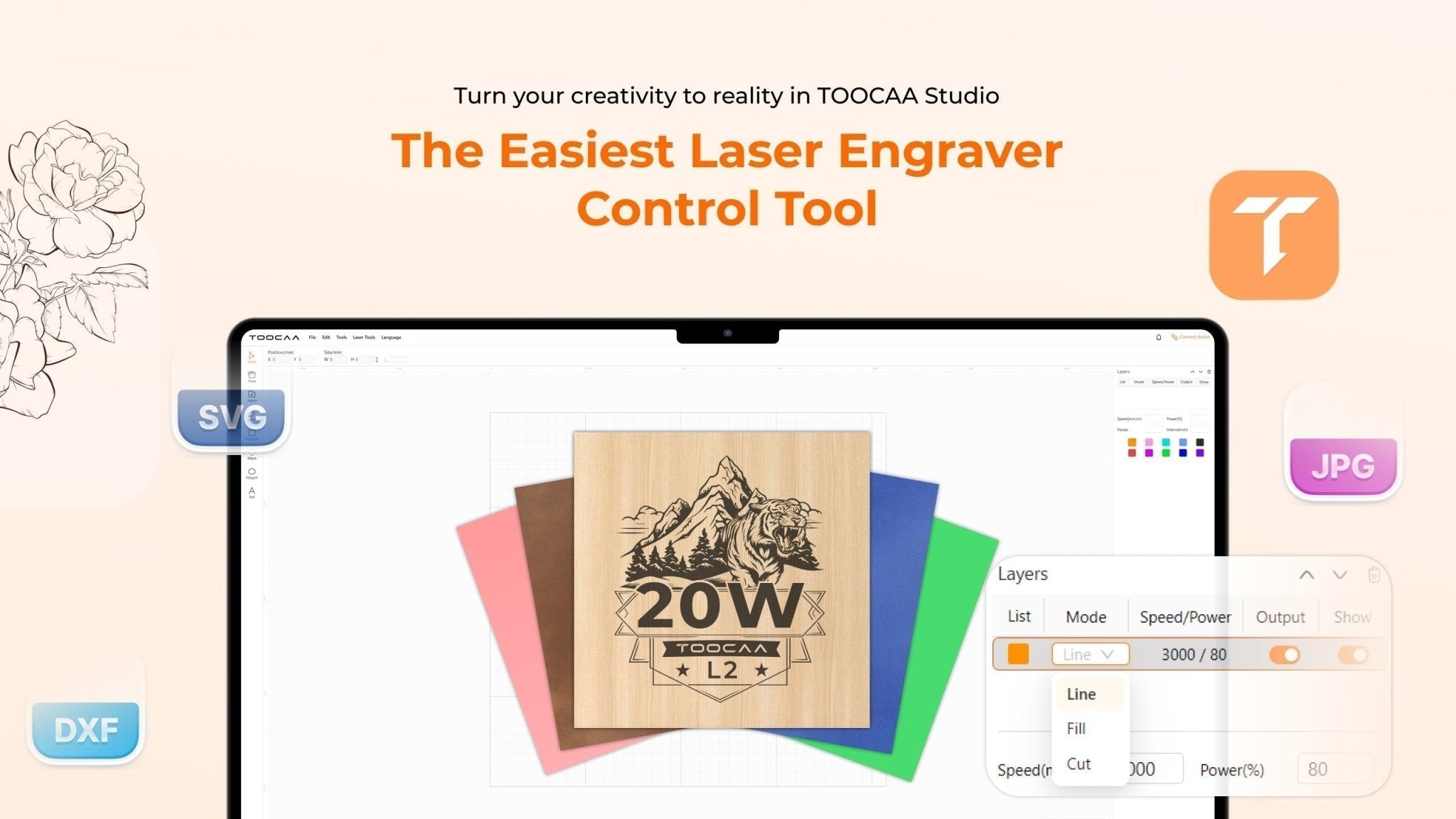

Laser engraving. Understanding it before choosing the right engraver

It’s important to understand everything around laser engraving equipment. This is the first step in buying the best one for your business, to get the most profit from it.

The great thing about this equipment is that it’s a precise and permanent marking and cutting process, that is done by a beam of light. It is important to understand that there are other types of engravers as well, however, most businesses choose these, above other machines.

Know what your business needs

The most important thing to consider before buying your engraver and cutter is to know what your business needs. Why do you need an engraver and cutter? Can you use a smaller, cheaper version or do you need to invest in the larger engravers that are more versatile, but also more expensive?

Many businesses are now starting to use engravers to make their products and business unique and they don’t need a large machine. But if your business is all about cutting and engraving on different materials, then a larger, more diverse machine will be a better option.

Factors to consider for your first laser engraver and cutter

To choose the right laser engraver and cutter, there are some factors to consider. Going through these factors will ensure that you won’t make a mistake, wasting money in buying something you can’t use.

The size of your available workspace

This is something important to know. Most laser engravers are large machines that need a large amount of space to function correctly. You will need to make sure that the available workspace where you going to install the machine is the right size.

Most commonly, businesses realize too late that their workspace isn’t large enough. Returning and changing machines from the manufacturer can be time-consuming. Making sure that you have enough space will save you lots of time and money.

The power you will need

Some of the smaller machines don’t have high power. Meaning that they can’t work on large materials or thick materials. Larger machines can cut through a large variety of materials, but it is also more expensive.

So, don’t purchase an engraver that has too much power for your business’s needs. And, don’t buy a small engraved if you know that you are cutting large materials in a short amount of time.

Materials that your business needs to engrave or cut

Different machines are using different materials to engrave on. Some machines can only engrave on plastic and metals. Other machines can engrave and cut a large variety of materials including stainless steel, brass, glass, acrylic, and rubber.

Something to consider is that you can choose between a CO2 laser engraver and a fiber laser engraver. To use a large variety of materials, you might want to consider the CO2 engraver.

How much you can afford?

It can be tempting to purchase a large engraver, even if you have a small business. This isn’t recommended, because of the price of some of these laser engravers and cutters. You should only buy the size you know you need. For a new business, a smaller cutter is recommended. If your business fails, you won’t need to worry about a large, expensive cutter.

Research different manufacturers, so that you can see where you can get the cheapest, but most recommended engraver and cutter. It is also important to reconsider buying secondhand cutters if this is something you thought about.

Maintenance costs

Yes, any mechanical machine like a laser engraver needs to be maintained if you want to get the most out of the machine. Some machines can’t be maintained at the business by the maintenance crew. Then, you need to hire people from outside to maintain the machine. It can cost a lot of money at the end of the day.

Consider the maintenance costs of the engraver. The engraver might be more expensive, but the maintenance costs will be lower. Remember that you are only buying the machine once, then you need to do maintenance every three to six months. It can become expensive to hire people from outside for the maintenance.

Support, you will get from the manufacturer

The last thing that you want is to have the manufacturer stop supporting you the moment you pay for the laser equipment. For any troubleshooting or installing problems you still want to be able to contact the manufacturer. You can ask the manufacturer what type of after-sale support you are going to get.

Will they come and assist with the installation or any troubleshooting you might have? Or, are they going to ask for additional fees for the call-out?

Conclusion

There are so many benefits to purchasing and investing in laser equipment. Especially when it comes to the engravers and cutters. Looking at statistics you will see that many businesses make a mistake with their first engraver purchase.

These are all the essential factors to consider when you are buying your business’s first laser cutter and engraver. Making sure that you don’t waste your company’s money. Now, your business can have the latest cutting technology that will benefit the business, and not waste money in buying the wrong laser cutter and engraver.