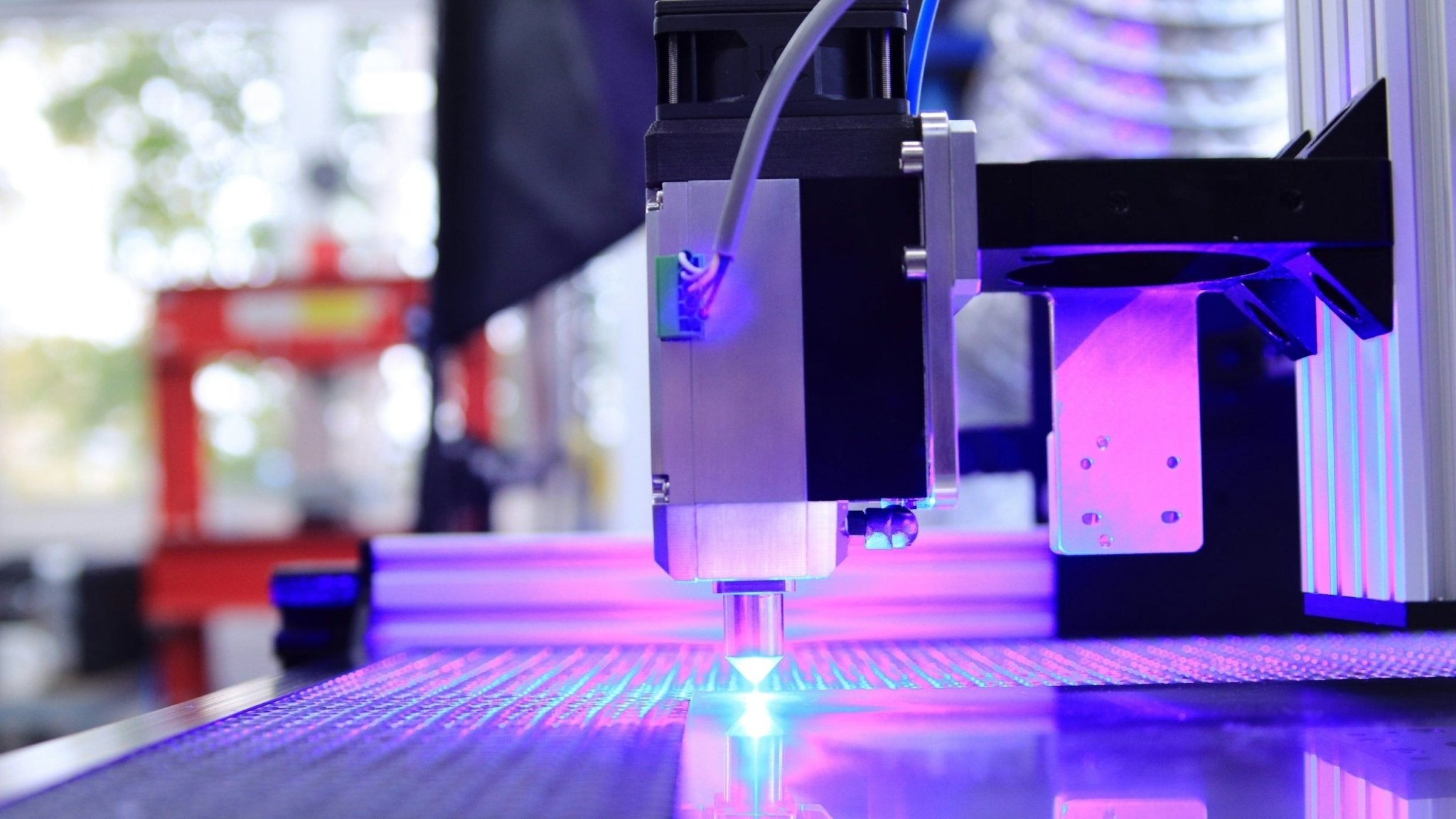

Many don’t know what type of material they can use with their laser cutter and engraving machine. Or, they don’t know the importance of choosing the right material. This can cause serious problems with your machine.

If you know what materials you can cut and engrave on, you will have a much better success rate with your projects. These are the best materials to work with on most laser cutters and engravers.

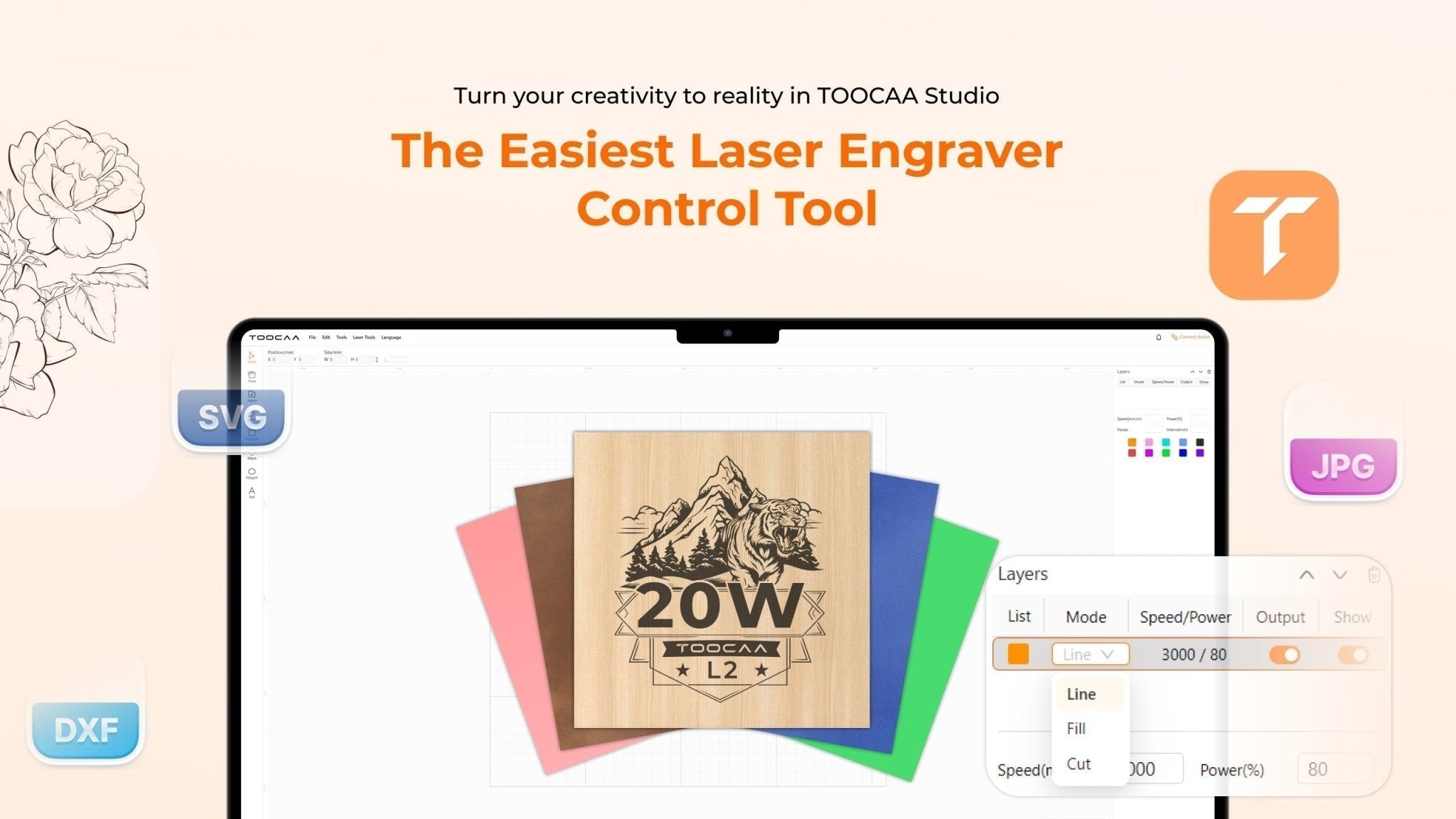

Reminder: Different laser engravers and cutters are compatible with different materials

Even if we are listing the top 10 materials you can use, there is something essential to consider. Not all the laser machines are compatible with all these materials. Some machines have more materials that you can use. Other, cheaper machines have fewer materials that you can use.

You need to know what material you want to use before you start searching for your first engraver. If you don’t know what material to use, then we recommend that you purchase a machine with a large variety of material compatibility.

Best materials to use on most laser cutters

These are the best materials to use in alphabetical order. To make it easier for you to see the material you consider is known as the best compatible material.

Cardboard

Cardboard is one of the cheapest materials to use. Many don’t realize that cardboard is compatible with laser machines. You can use the corrugated and single-ply cardboard on a laser cutter.

These cardboard cutouts are used for things like packaging prototypes, gift boxes, architectural models, and other cardboard uses. Cardboard is cheap and easy to cut with a laser machine. Making this ideal for prototypes.

Certain fabrics

Fabrics that include denim, felt and cotton can be used on laser cutters. It can be cut from the most delicate materials like silk to hard and thick denim materials. Materials can be used for quilting, custom designs, and even home décor.

Many are also considering and experimenting with cutouts for clothing. Because of the way the material is cut, you don’t need stitching or fraying edges. It leaves a smooth, precise cut.

Glass

Glass is more suitable for engraving and etching, but with the right laser cutter, you can cut glass as well. The right thickness for cutting is required. However, it can engrave on all types of glass including glassware, trophies, and awards.

Laser engravers leave glass engraving with fine detailed work. It can also have a frosted look that makes any glass piece special and unique.

Leather

Using a laser engraver and cutter can be fun for any leather maker. Leather can be engraved and cut with most laser engravers. You can make anything from wallets to bets and bags from the engraver.

Leather is expensive, but with the laser machine, you will get high-quality engraving cuts that are special and easy to do.

Metals

Metals, more specifically fabricated metals like aluminum, brass, tin sheets, and stainless steel are the most used materials with a laser cutter. It is important to know that not one laser cutter can handle thick metals.

Thin fabricated metals can be used for making signs, jewelry, metal parts, and industrial designs. This is a material that is more expensive than other engraving materials.

Paper

Paper, not the normal writing paper is suitable for laser cutting. We are talking about cardstock and construction papers. You can make use of a laser engraver and cutter to make bulk orders of greeting cards, invitations, etc.

Using a laser cutter with paper will ensure precise cuts and engraving. Every time. It is also a cheap method that you can use to make packaging for your sold items.

Plexiglass

Plexiglass, also known as acrylics is the most popular material to use with a laser cutter and engraver. The main reason for this is the versatility and different colors and thickness of the acrylics.

Acrylics or plexiglass are used for decorative items, awards, jewelry, and signages. It can be used for engraving and cutting. Making this a cheaper material to use.

Rubber

Natural and synthetic rubber sheets are used on laser engraves without any problems. In fact, most people recommend rubber objects will ensure durable cuts and engraving. We are talking about things like gaskets, seals, and stamps.

The benefit of using laser cutters on rubber is that it gives a clean cut with no additional finishing needed. Making it economical.

Stone

Stone like marble, slate, and granite can be cut and engraved on with most laser cutters. However, some laser cutters won’t be able to cut through the thicker slabs of granite and marble. It is perfect to use for engravings like custom engraved plaques, signage, and decorative pieces.

It will be able to do deep engraving that will last for a long time. The downside is that not all laser cutters can cut the stone.

Wood

Wood, more specifically plywood, MDF, and hardwood can be cut and engraved on with a laser cutter. The most popular wood that is used with laser machines are the plywood and MDF. The main reason for this is the cost-effectiveness of these woods.

You can make anything from furniture, engravings, models, and crafts from wood when you are using a laser machine.

Choosing the right material for your project

Before you can start your project on your laser cutter, you need to make sure that you choose the right material for your project. And, you need to make sure that your cutter is compatible with the materials you want to use.

Successful laser cutting and engraving projects depend on the material that you use. This is why knowing the best materials for laser cutting is essential. These are just the top 10 materials to use. Other materials can be used on some laser cutters as well but you will need to research it, to ensure compatibility with your engraver.

And i'm glad to share this video to you: Engraving Stones: Size, Shape, Density & Aggregates. He showed the effect of carving different styles of stones, compared the carving area and the colors carved out of different stones, gave some suggestions and inspiration references for carving, which I thought was quite good and wanted to try stone carving. I hope this video will help you as well!