Lasergravurmaschinen sind moderne Werkzeuge, die für ihre Geschwindigkeit, Zuverlässigkeit, Genauigkeit und Vielseitigkeit bekannt sind. Sie können mit einer Vielzahl von Materialien arbeiten, darunter Kunststoffe, Metalle und Keramik, sodass Sie Ihre kreativen Konzepte in greifbare Ergebnisse umsetzen können. Angesichts der Vielfalt der verfügbaren Optionen kann die Auswahl der für Ihr Unternehmen am besten geeigneten Lasergravurmaschine eine komplexe Aufgabe sein. Jeder Maschinentyp hat seine eigenen Vorteile und Einschränkungen, weshalb es wichtig ist, diese Faktoren vor dem Kauf gründlich abzuwägen. Die folgenden Richtlinien bieten einen strukturierten Ansatz, der Ihnen dabei hilft, eine fundierte Entscheidung zu treffen.

Wichtige Überlegungen zum Kauf einer Lasergravurmaschine

Grundprinzipien der Lasergravur

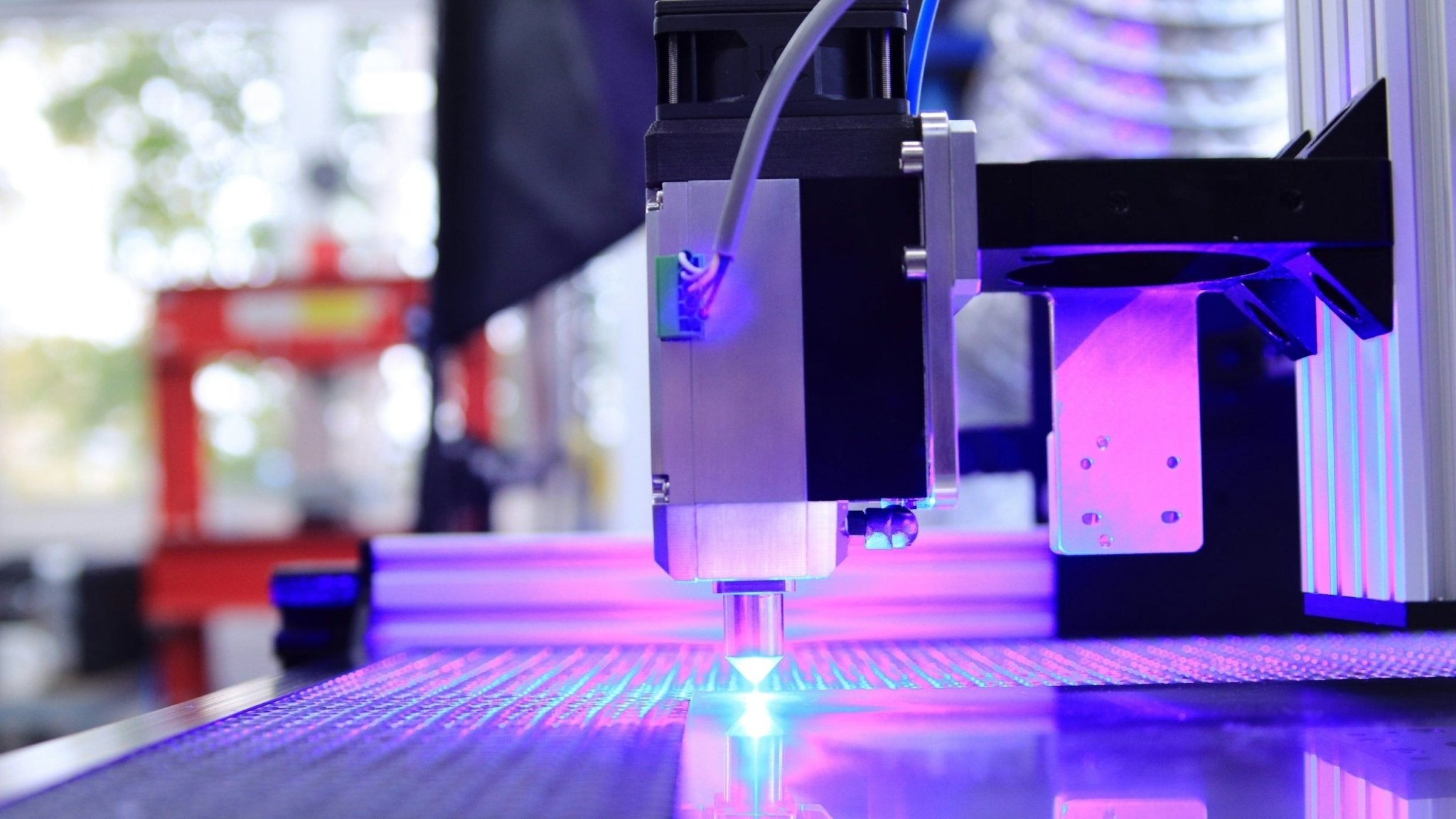

Bei der Lasergravur werden Materialien mithilfe eines konzentrierten Laserstrahls präzise erhitzt, wodurch sich die Farbe des Materials ändert und je nach Einwirkungsdauer ein Kontrast entsteht. Das Verständnis dieses Prozesses ist für die Auswahl des geeigneten Typs einer Lasergravurmaschine von entscheidender Bedeutung.

- CO2-Lasergravurmaschinen: Diese Maschinen verwenden eine Mischung aus Kohlendioxid, Stickstoff und Heliumgasen, um den Laserstrahl zu erzeugen. Mit einer Wellenlänge von 10,6 Mikrometern sind CO2-Laser äußerst effektiv zum Gravieren und Schneiden nichtmetallischer Materialien wie Holz, Kunststoff, Leder und Acryl.

- Faserlaser-Graviermaschinen: Faserlaser verwenden eine faseroptische Laserquelle, um hochintensive Strahlen durch eine Reihe von Glasfasern zu erzeugen. Mit einer Wellenlänge von 1,06 Mikrometern eignen sich Faserlaser besonders gut zum Gravieren von Metallen wie Edelstahl, Aluminium und Kupfer.

- Diodenlasergravurmaschinen: Diese Maschinen verwenden Halbleiter, um einen hochfokussierten Laserstrahl zu erzeugen. Wenn elektrischer Strom durch den Halbleiter fließt, erzeugt er einen konzentrierten Strahl. Mehrere Dioden können kombiniert werden, um einen leistungsstärkeren Laser zu erzeugen, der sich ideal für die Arbeit mit empfindlichen Materialien wie Glas eignet. Diodenlaser arbeiten in einem Wellenlängenbereich von 400 bis 2000 Nanometern und bieten im Vergleich zu herkömmlichen Lasern eine präzise Strahlausrichtung mit minimaler Wärmeableitung.

Überlegungen zur Materialkompatibilität und Maschinentypen

-CO2-Lasergravurmaschinen: Diese eignen sich zum Gravieren von nichtmetallischen Materialien, einschließlich Gips, Holz, Faserplatten, Fliesen, Papier, Leder, Kunststoff, Acryl und Gummistempeln.

-Faserlaser-Graviermaschinen: Faserlaser wurden für Metallmaterialien entwickelt und eignen sich gut für die Bearbeitung von Kupfer, Aluminium, Stahl und Aluminiumlegierungen. Sie werden häufig für Anwendungen wie die Nummerierung von Metallteilen, Identifikationsmarkierungen, Firmenlogos und Ätzungen verwendet. Die Wellenlänge von 1.060 nm ermöglicht effiziente Schwarzmarkierungen und Tiefengravuren.

- Diodenlaser-Gravurmaschinen: Diese Maschinen eignen sich für eine Reihe von Materialien, darunter Holz, Leder, Gummi, Edelstahl, eloxiertes Aluminium und Papier.

Sicherheits- und Betriebsvorkehrungen

Beim Betrieb einer Lasergravurmaschine sind entsprechende Sicherheitsmaßnahmen unerlässlich, um schwere Verletzungen und Gefahren zu vermeiden. Beachten Sie die folgenden Sicherheitsempfehlungen:

- Laserstrahlen sind hochintensiv und unsichtbar; direkte Einwirkung kann zu schweren Verbrennungen und Augenschäden führen. Tragen Sie beim Arbeiten mit Lasergeräten immer eine geeignete Laserschutzbrille. Die Schutzbrille von Toocaa bietet hervorragenden Schutz und ermöglicht gleichzeitig eine klare Sicht auf den Gravurvorgang.

- Lasergravurmaschinen bergen potenzielle Brandrisiken. Stellen Sie daher sicher, dass Feuerlöscher leicht zugänglich sind. Toocaa-Maschinen sind mit Flammenerkennungssystemen ausgestattet, die bei Funkenerkennung rechtzeitig Alarm schlagen und so dazu beitragen, Brandgefahren zu verringern.

- Während des Gravurvorgangs können giftige Dämpfe und Rauch freigesetzt werden. Es ist wichtig, ein gut gewartetes Absaugsystem zu installieren, um Rauchansammlungen in Innenräumen zu verhindern und das Inhalationsrisiko zu verringern. Toocaa-Maschinen verfügen über fortschrittliche Absaugsysteme und Ventilatoren, die Rauch und Staub effektiv filtern und abführen.

- Informationen zu den richtigen Betriebsverfahren finden Sie immer im Produkthandbuch. Das Einhalten eines Sicherheitsabstands ist eine weitere wirksame Möglichkeit, potenzielle Risiken zu minimieren. Stellen Sie bei Reinigungs-, Wartungs- oder Reparaturarbeiten am Gerät sicher, dass die Stromversorgung unterbrochen und das Netzkabel ausgesteckt ist.

Kostenüberlegungen

- CO2-Lasergravurmaschinen: Großformatige CO2-Lasermaschinen mit einer Leistung von 30 W bis 500 W können große Teile und verschiedene Materialien wie Holz, Glas, Acryl, Stoff, Leder und Gummi bearbeiten. Die Kosten für diese Maschinen liegen normalerweise zwischen 15.000 und 150.000 US-Dollar.

- Faserlaser-Graviermaschinen: Diese Maschinen mit einer Leistung von 20 W bis 60 W kosten zwischen 3.000 und 10.000 US-Dollar. Faserlaser bieten im Allgemeinen eine höhere Gravureffizienz als CO2-Laser.

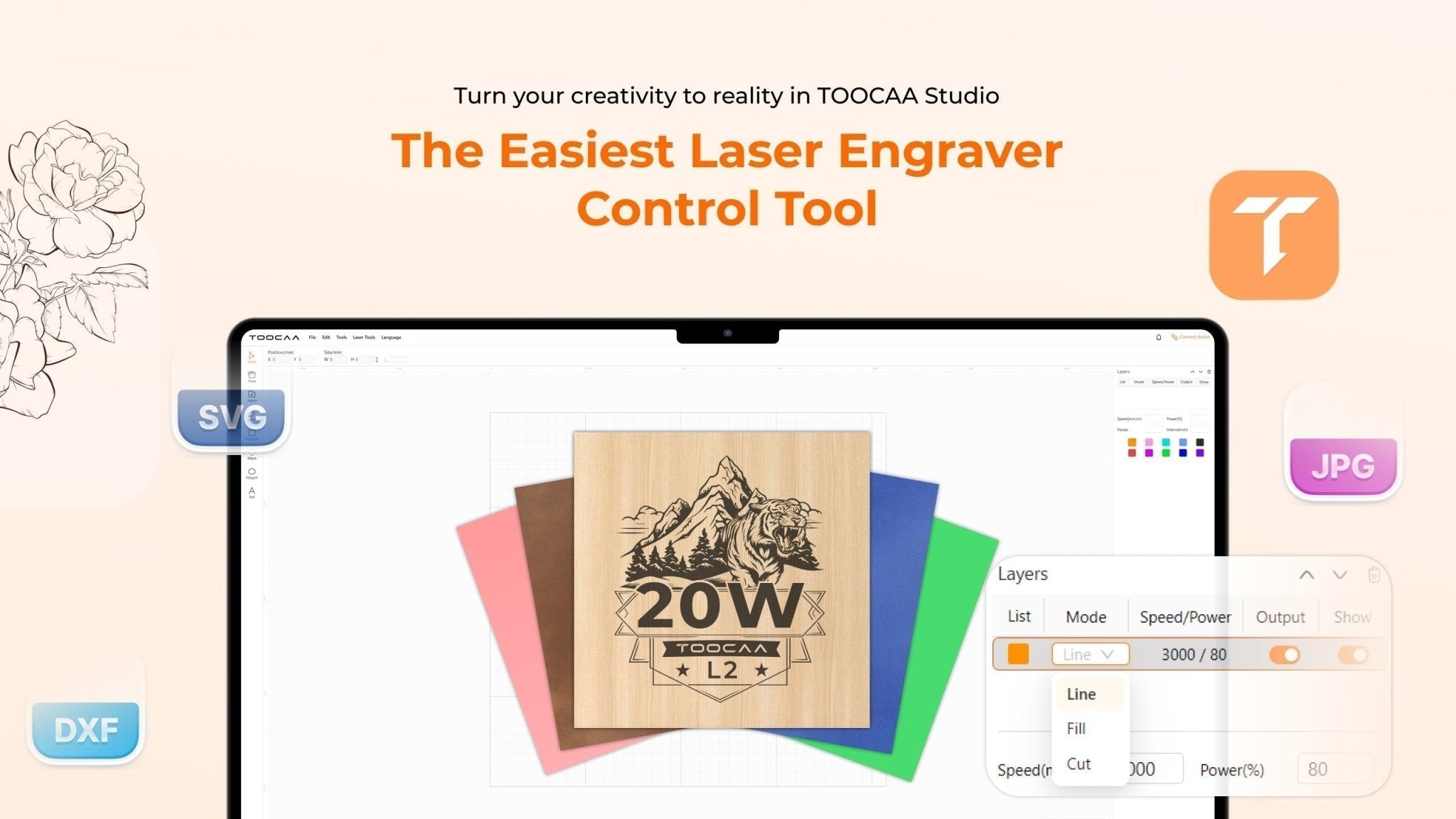

- Diodenlasergravurmaschinen: Mit einer Leistung von 5 W bis 60 W kosten Diodenlaser zwischen 500 und 5.000 US-Dollar. Aufgrund ihrer Erschwinglichkeit und Benutzerfreundlichkeit sind sie eine ausgezeichnete Wahl für Anfänger und Bastler.