The world revolves around technology, and its application is visible in every industry. Gone are the days of manual cutting styles, which lack precision with large margins of error.

Plus, the old system of manually cutting is highly tedious. This is where laser cutting machines come in.

As a manufacturer or producer, your business is incomplete without a laser cutting machine. Over the years, laser cutters have improved production by 300%, so they have become a core instrument in workshops that require cutting different materials.

However, it is important to choose a machine that suits your needs, which can be a daunting task.

For example, you want to consider the right type of laser cutting machine that work with your materials. While some laser cutters are designed for cutting metals, others are for cutting non-metals. Other factors include budget, warranty, power, and cutting speed.

This blog post discusses, in detail, the key factors to look out for before choosing a laser-cutting machine.

Laser Power

Most of the time, people don't understand the meaning of laser power and end up buying a laser cutting machine that is lower or higher than required.

For instance, you might need a laser cutting machine that cuts metals, but because you don't understand the principles behind laser power, you purchase the one that only cuts wood or acrylic.

Laser power describes the laser tubes measured in watts and their cutting and engraving abilities. Tubes with higher watts can cut thicker objects with greater speed and accurate precision.

On the other hand, laser cutters with lower watts can only cut materials within a certain thickness. Therefore, the right laser power for your machine depends on your choice and what you want to cut.

We understand most people would prefer to purchase powerful tubes with higher watts, but this comes with a downside. These tubes are difficult to handle at lower powers and do not give perfect results when used for engraving. Therefore, we advise a range of 25-80W to have a perfect cut and engraving.

Another challenge with powerful laser power is that they are difficult to maintain. Powerful laser tubes require a strong cooling system, which may be expensive for small-scale business owners or individuals to purchase. Also, the cost of replacement is high.

Nonetheless, the laser cutter you purchase must depend on your business needs.

2. Types of Laser Cutters

Laser cutters are of different types and mechanisms. Here are the common types:

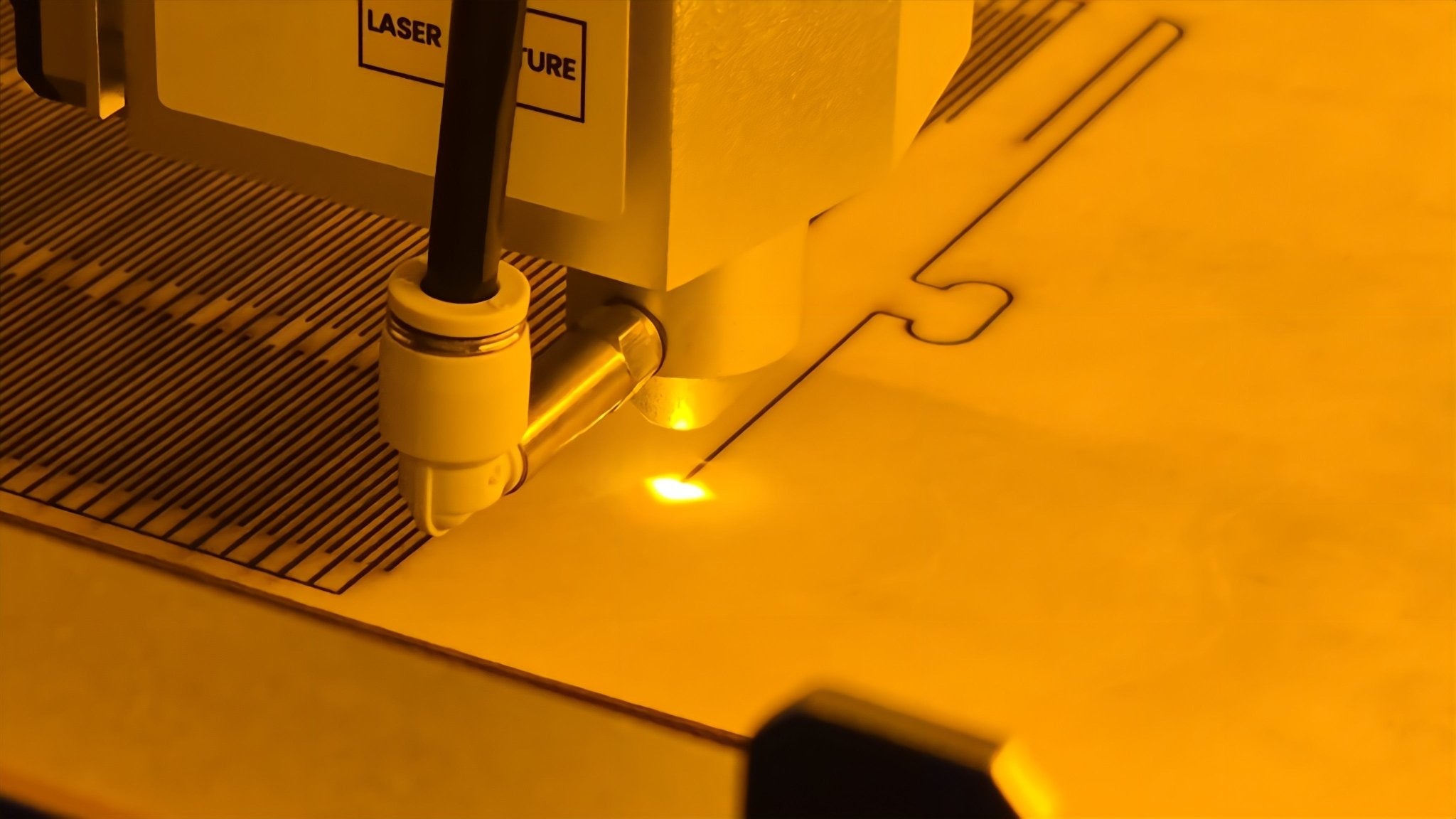

CO2 Laser Cutters

CO2 laser cutters are one of the oldest and most common type of laser cutter you will come across. They have been in existence for over 20 years and are used in most manufacturing and production companies.

Key features of this cutter are efficiency, affordability, easy maintenance and repair.

CO2 laser cutting machines are produced from a combination of CO2, helium, and nitrogen. When these gases are charged up, they produce laser beams with a wavelength of 10.6mm.

Hence, they are an excellent choice for cutting acrylic, glass, leather, plastics, wood, and non-metals.

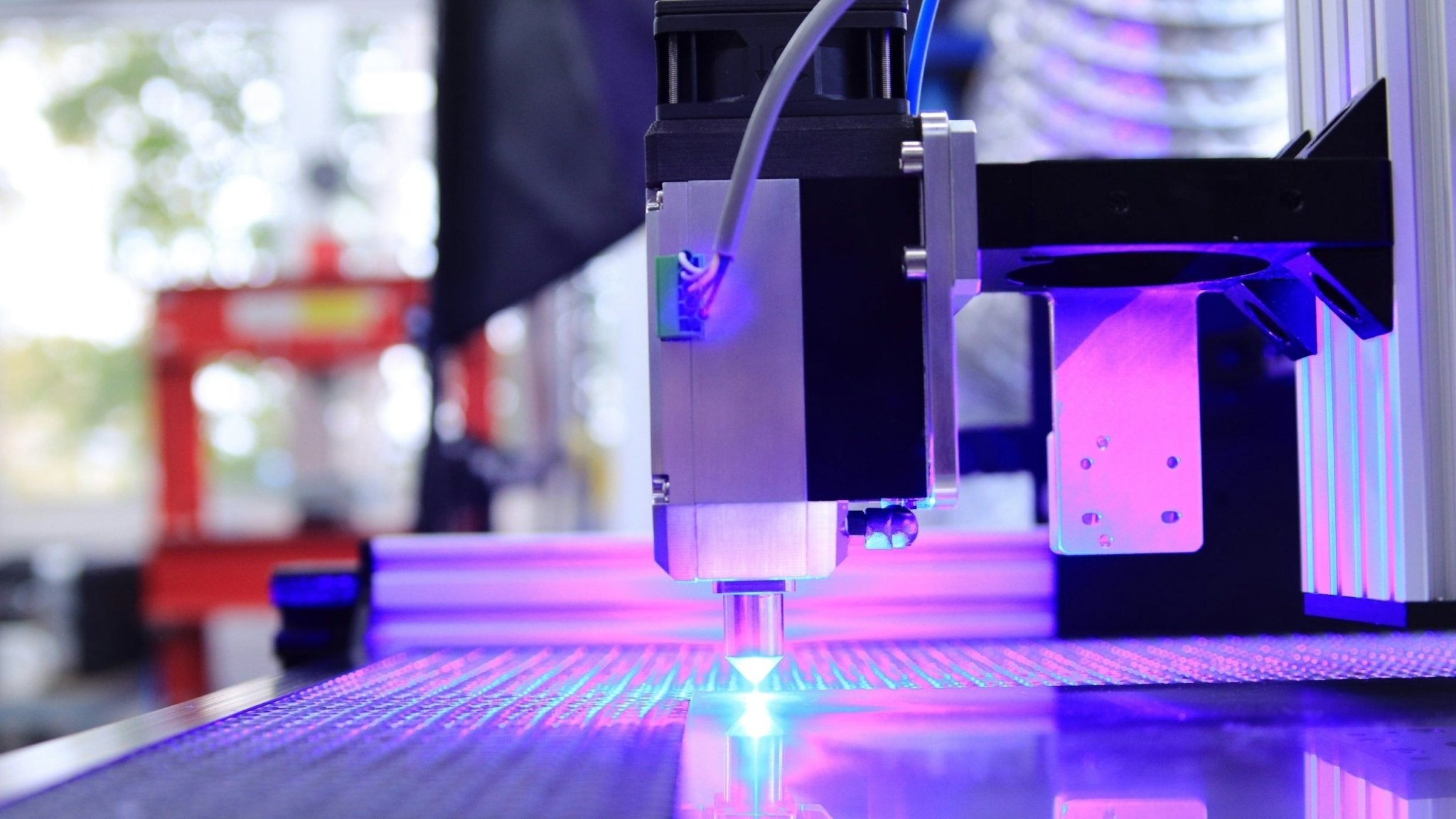

Fiber Laser Cutters

Fiber laser cutters, also known as solid-state lasers, were introduced in 2008. They use seed lasers magnified with special fibers and work well with metal and organic materials.

Fiber laser cutters are four times more effective than CO2 laser cutters due to their ability to cut conductive and reflective metals. However, they have their disadvantages.

Fiber laser cutters are expensive and require experience to handle due to their high cutting speed. Plus, they require more maintenance than other cutters and repairs may require the assistance of the manufacturer.

Diode Laser Cutters

Utilizing semiconductor laser diodes with wavelengths of

450 nm (blue) or 808 nm (near-infrared), diode laser cutters operate at 5-40 W power, ideal for engraving and cutting thin non-metallic materials like paper, wood, and acrylic. Their compact size, low cost (1/3 of CO₂ systems), and compatibility with Arduino/Raspberry Pi make them perfect for DIY projects and small-scale industrial tasks such as custom keychains or electronic component labeling. Compared to CO₂ (thick non-metals) or fiber lasers (industrial metals), diode laser engraver prioritize affordability and portability for hobbyists.

Check out this TOOCAA L2 Desktop Laser Engraver & Cutter.

3. Budget

Choosing a laser cutting machine is principally determined by your budget. For instance, if you are on a tight budget, we advise you to go for a CO2 laser cutter over fiber because of its affordability.

Setting up a budget upfront helps avoid overspending. Also, it will help you get the best within your budget range. Note that it is okay to purchase a small sized laser because it's within your budget.

Another reason we recommend having a budget is that it helps determine whether to purchase a brand-new or refurbished laser cutting machine.

4. Purchase and Operational Costs

Purchasing a laser cutting machine is one thing. Dealing with the operational cost is another. The price for purchasing a laser machine is one-quarter of the total cost that would be spent.

As a buyer or business owner, you must consider maintenance costs, energy consumption and other operational costs that come with owning a laser cutting machine.

However, this is dependent on the type of machine purchased. Fiber laser cutters have high maintenance and operational costs compared to CO2. Hence, when making a choice, consider laser-cutting machines that are easy to maintain.

5. Automation

There are various degrees of automation. The newer the technology, the higher the automation. What increased automation does is to increase productivity and reduce the need for manual labor, thus saving time.

6. Space Requirements for Installation

The amount of workspace available determines the type of laser machine you should get. Take into consideration your space size and remember to include installation and ventilation space.

Your space should be large enough to accommodate those who would help you install the machine. It should also be large enough to accommodate those who come periodically to check on your machines when faulty.

It would be disheartening if you get a large laser-cutting machine but have no space for installation because the machine has taken over 90% of your workspace.

Another factor you should consider is ventilation. Large CO2 laser cutters require extra cooling systems, because of their size. Therefore, if you purchase a large laser cutter, provide enough ventilation.

7. Service and Support

Laser cutting machines are more automated than manual cutters, making them easy to use. However, in the early stages especially if it's your first time using a laser cutter, there might be some hurdles along the way.

For example, you are using your machine and it stops working in the middle of a production. The next step is to reach out to customer support or their technical unit to lay your complaints.

When you do, and you are told to wait 36 to 48 hours before you are attended to, how would you feel? Horrible!

On the other hand, if you reach out to customer care and they respond promptly and attend to your situation, how would you feel? Elated!

Therefore, it's important to ask the right questions before purchasing a laser cutting machine from a company or supplier.

Necessary questions to ask your supplier include: Do I have access to a technician? Is there a functional online customer care service that responds within minutes? Are there videos that can help first-time users navigate their way around the machine? Are the spare parts available?

These are important questions you should ask your supplier or manufacturer before purchasing a laser-cutting machine from them. To make this easy, use the internet to source for manufacturers or suppliers with excellent reviews and good services.

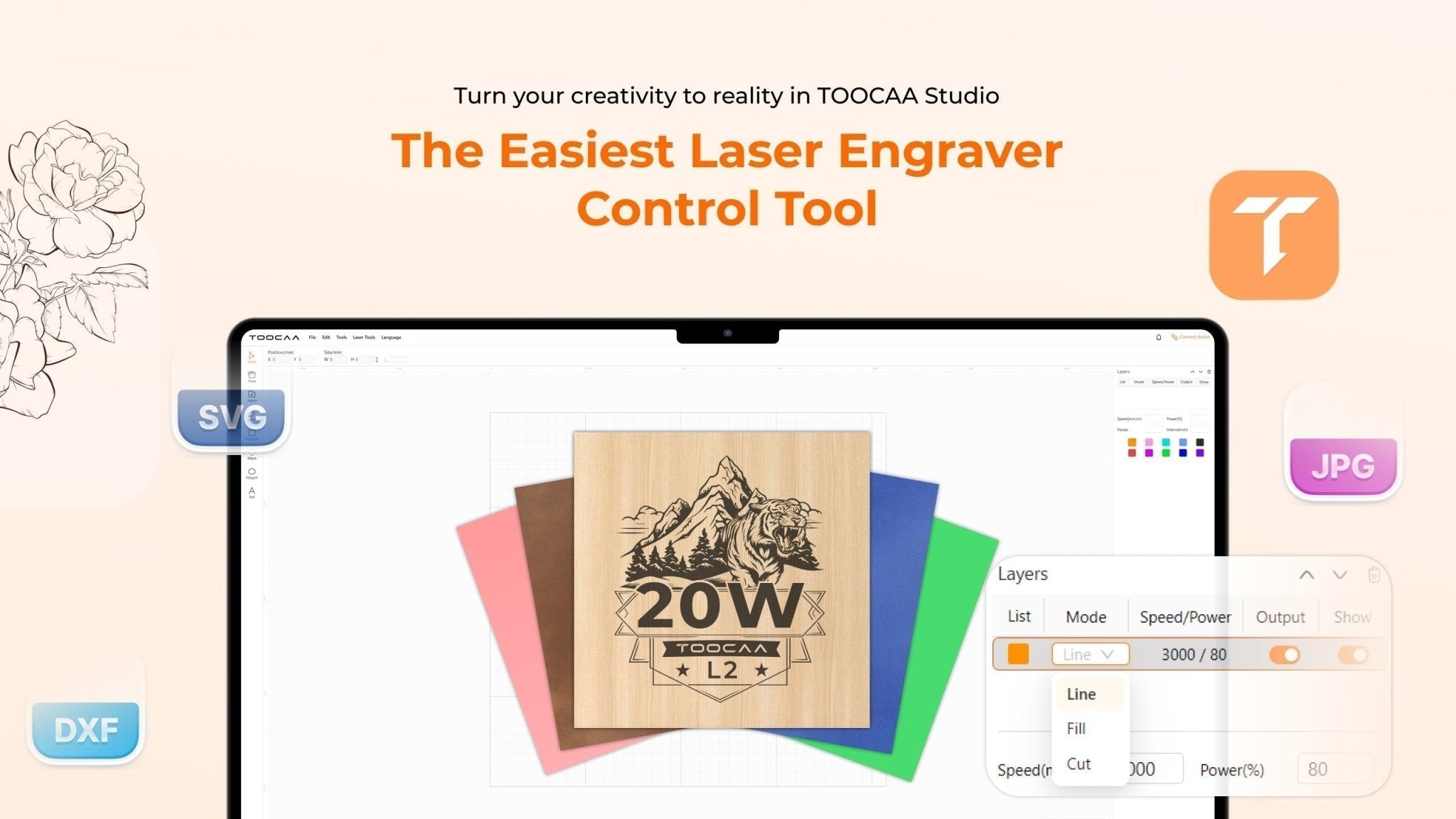

8. Software Integration

All laser cutting machines have software embedded in them. This depends on the type, size and use of the machine. Common examples include Metalix, BySoft, Open Source and Free Software, Nesting Software Control SoftwareCAM Software and Simulation Software.

This software plays a vital role in the performance, precision and effectiveness of the cutting process. With advancements in technology, this software can control laser speed, power and depth.

Therefore when getting a laser cutting machine ensures that the software integrated is compatible and suitable with your needs. Compatibility increases efficiency, smooth operation, and general performance and reduces the chances of errors in the machine.

Toocaa Studio stands out as a versatile option among cutting software solutions, offering a unique approach compared to traditional embedded software. Toocaa Studio is a free, web-based cutting software that requires no downloads or installations. With its clean and intuitive interface, it ensures a seamless user experience while respecting your privacy by not collecting any personal data. Perfect for those seeking simplicity, security, and efficiency in their cutting tasks.

9. Return on Investment (ROI)

The primary aim for investing heavily in a laser cutting machine is for profit and returns. The versatility of laser-cutting machines makes it easy for business owners to profit from their investments.

However, before you invest, consider the following:

What are you processing or producing? What is the size of your products? What is the amount of laser power needed?

Your answers to the above questions will help determine how much to invest and how much returns you would make.

10. Cutting Speed

Increased cutting speed is directly proportional to increased productivity. The faster the cutting speed, the more products you can produce quickly. Please note that the speed is also determined by the types of materials and laser-cutting machines used.

For instance, the cutting speed of metals and plastics would be different because they are of varying thickness.

For further clarification, read the user manual, which provides a list of cutting speeds.

Check out our laser cutting machine materials.

11. Safety Features

In the UK, laser cutting machines are categorized into 4 classes. Class one is the most common and safest of all. It is used in hospitals, schools, manufacturing, and production companies. Key features of class one include safety sensors on doors, a protection circuit for the laser tube, and automatic power cut-off in cases where the lid is mistakenly opened.

Class 4 is the least safe and requires professional expertise and 100% extra precaution. This includes wearing a protective shield, goggles, and clothing when handling.

12. Warranty

Laser-cutting machines are expensive and some require high maintenance. To prevent expensive repairs, buy laser cutters with at least 24 months warranty. The warranty period is the manufacturers' way of communicating the quality of the machine. Therefore, if you see a laser cutting machine with less than 2 years warranty, it's a subtle way of letting you know the product is not 100% quality.

Buying a laser cutting machine with a higher warranty means that you are getting high quality, efficiency, and peace of mind. It also gives the assurance that the product will last for a long time. However, this warranty does not include refurbished laser cutting machines, as theirs is 12 months.

Take a look at our list of laser machine accessories for you cutting machine.

13. Environmental and Safety Factors

Particles and gases are released during cutting. Therefore, purchase laser cutting machines that comply with federal and state environmental regulations and safety standards. Buy machines with good exhaust systems to reduce emissions from gases, fumes, and particles. This is not just for your safety but also for the environment.

Conclusion

There are many factors to consider before choosing a laser cutter. Factors like the cutting speed, return on investment, safety, and the type of cutting machine are important considerations to make when choosing a laser cutter.

We have made it simple for you by discussing in detail the key factors so that you can make the best decision. Invest in machines that are suitable to your needs.

For example, if you work with metals, fiber laser cutters are the best option. For non-metals, diode laser cutters are more compact and cost-effective, making them ideal for hobbyists and small projects. They excel in cutting thinner materials and are particularly effective for detailed engraving tasks. However, they may not handle thicker materials as efficiently as CO2 laser cutters. Having this knowledge at your fingertips can save you a lot of money, time, energy, and effort. This video can serve as an intuitive summary to help you better choose different types of laser cutting machines.

Do you need further guide on how to choose the right laser cutting machine that suits your needs? Contact us now.

You can also check our website for other laser-machine-related materials and accessories.