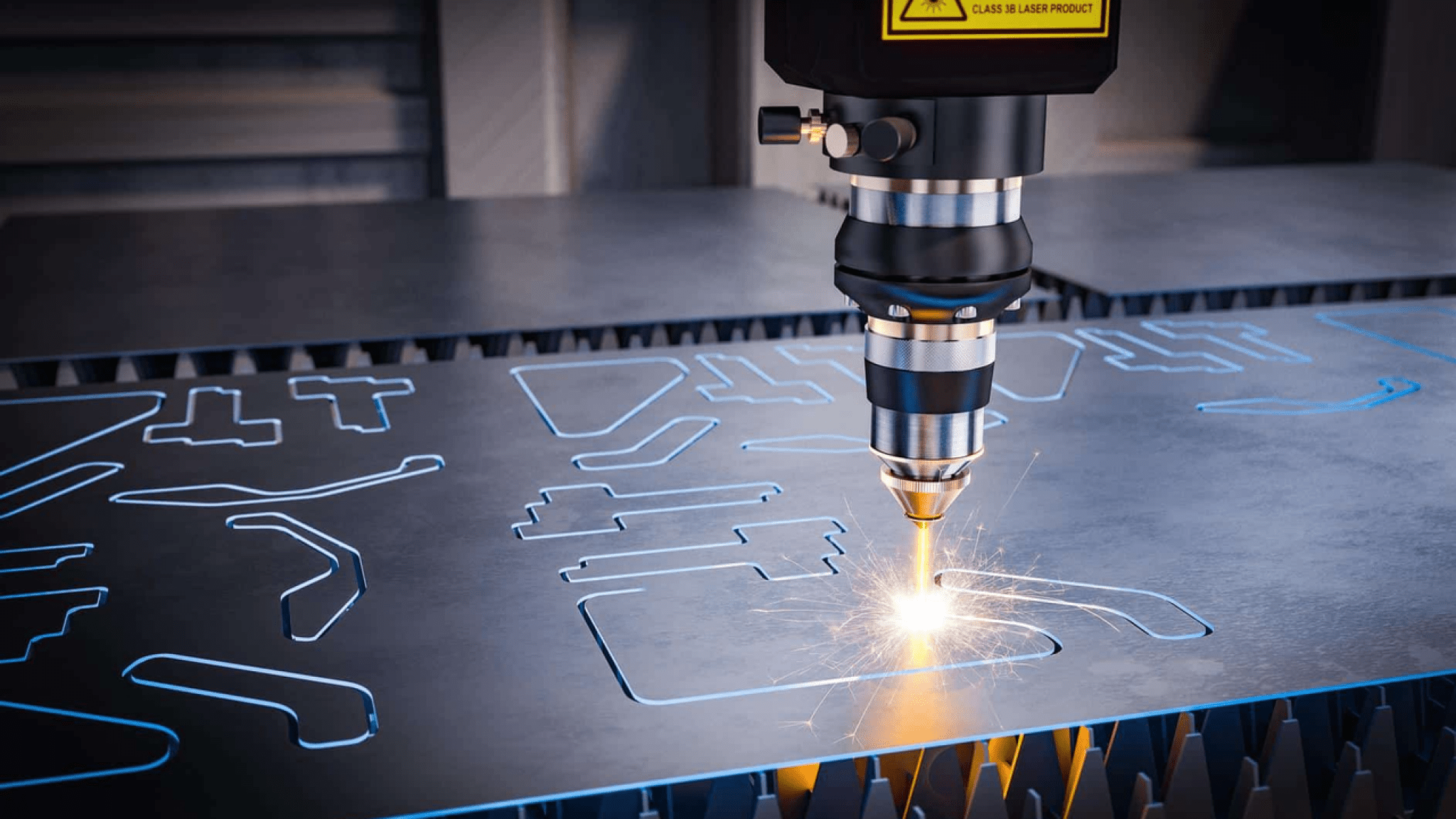

Why do most industries prefer laser-cutting machines over traditional means? Simple! It's because of their ease of use, efficiency, precision, and time-saving powers.

Hence, laser-cutting machines have practical applications in many industries. In the 21st century, a sector that doesn't utilize these machines hardly exists.

But in what applications is a laser cutting machine used?

Depending on the type, a laser cutting machine is always dedicated to cutting different materials, such as metal, wood, fabric, glass, plastic, or polymer, and an industry can use it for different purposes.

This article explores the applications of laser-cutting machines in various industries.

What is Laser Cutting?

Laser cutting uses laser, a large beam of light generated by a laser source, to cut and engrave materials. It is an effective cutting method since it is 100% precise, leaving no margin of error.

Most industries are turning to this amazing technology not only for its precise cutting and shaping ability but also because it prevents material waste.

With a growing population, there's a need for daily equipment production, and you will agree when we recommend laser cutting machines to minimize production wastage.

However, it is important to note that laser cutting is categorized into three:

Remote Cutting

Remote cutting is used when working with thin materials because of their weight. This process partially removes metals and excludes the cutting gases (CO2, helium, and nitrogen).

Flame Cutting

The materials are subjected to acetylene or natural gas to melt their surfaces.

Fusion Cutting

Argon and other inert gases serve as cutting gases used to melt materials. Inert gases prevent chemical reactions with atmospheric oxygen, so the metal's surface may not be subjected to further treatment.

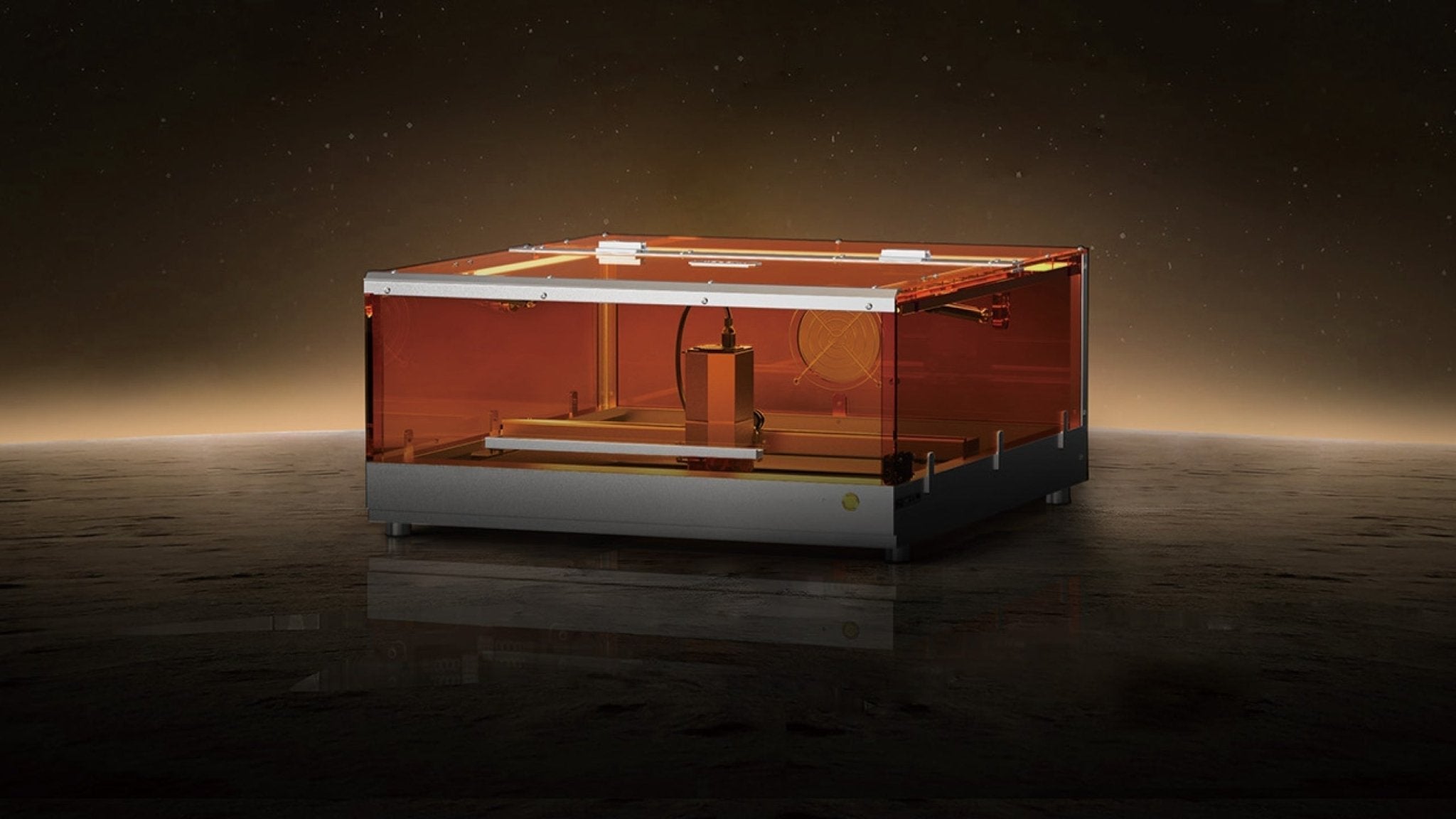

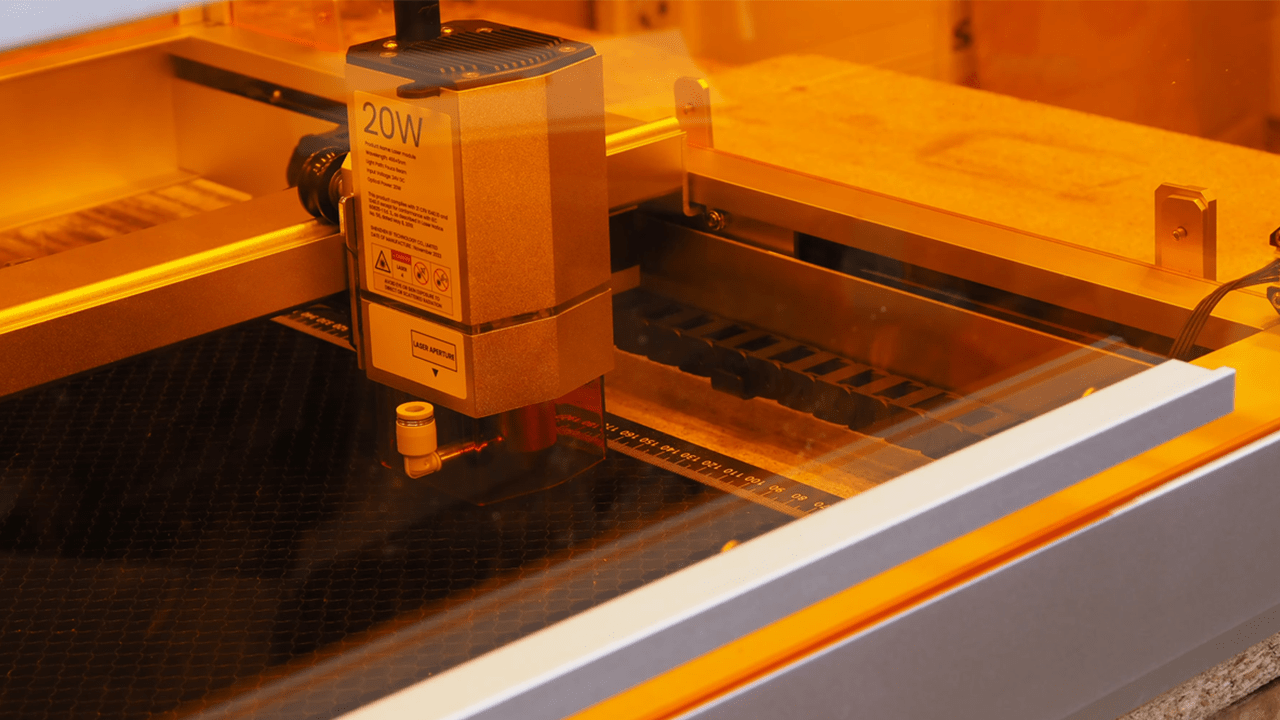

Check out this Toocaa L2 laser engraver cutter.

Industrial Applications of Laser Cutting

Automobile Industry

Laser-cutting machines are a blessing to the automobile industry. Over the past few years, there has been an increased production of complex, high-end automobiles. Also, in the automobile industry, there is no room for error; therefore, there's a need to ensure accuracy and precision in manufacturing materials.

Laser-cutting machines reduce the need for additional finishing touches or extra machining. This ensures the standards required in automobile manufacturing are being maintained. Examples of parts that are produced include:

· Body panels

· Engine bracket

· Chassis components

· Trunk lids

· Door frames

· Fuel tanks

· Windshield

· Roof panels

· Motor mount

· Brackets

Windshields and every product are made of high-tensile steel and aluminum.

Aerospace Industry

Laser cutting machines are more advantageous than traditional cutting methods in aerospace. They are faster, more precise, and safer for humans. They can be used to cut a variety of materials at varying thickness. This makes them an essential tool in the aerospace industry.

Laser-cutting machines are used in the manufacture of aircraft and spacecraft parts such as:

· Engine casings

· Turbine blades

· Fasteners

· Panel assemblies

· Wing structures

· Exhaust cones

· Fuel tank components

· Locking mechanisms

· Heat shields

· Gaskets

Laser-cutting machines are created with top-tier technology that helps minimize material waste. It reduces the rate of thermal distortion and preserves the integrity of aircraft and shift craft materials.

We believe that these machines will forever be valued in the aerospace industry. This is primarily due to the need to produce more aircraft to cater human wants and needs. Another is to produce aircraft that are lightweight following the regulatory safety standards.

Medical Industry

Laser-cutting machines deserve high praise for producing high-quality medical equipment, complex designs, and patterns that traditional means cannot achieve successfully. Precision and accuracy are two terms held dearly in the medical world because of how delicate human life is.

For example, pacemakers, implants, hip replacements, knee replacements, and spinal implants are always customized to fit the patient's body and for proper functionality.

Another benefit of laser-cutting machines is their ability to produce more parts in bulk at a fast rate. This is a huge blessing in the medical field because of the high demand for this equipment.

Other examples of tools that are produced by laser technology are:

· Dental implants

· Stents

· Surgical instruments

· Spinal implants

· Catheters

· Gaskets

· Endoscopic tools

· Knee replacements

Electrical Industry

Laser-cutting machines are a breath of fresh air in the electrical industry as they are used in making electrical boards, circuit boards, connectors, and other equipment used in homes and businesses.

For example, with laser technology, you can drill holes as tiny as 0.03 to 0.05 mm. This is important because as technology advances, we must discard obsolete and cumbersome ways of making heavy and complex devices.

We should stick to smaller and much more intricate types. All laser cutting machines cut with 100% accuracy with less than 0.01% margin of error.

Fitness Equipment

Laser-cutting machines are relatively new to the manufacture of gym and fitness equipment compared to other industries. Nonetheless, there are benefits to using laser cutting machines over traditional cutters.

They are time-saving and durable. Finally, they are more environmentally friendly, as the conventional method creates more unhealthy waste and fumes for us and the environment.

Pipe Processing

The pipe processing industry is one of the many beneficiaries of laser cutters. They can cut all types of pipes into various diameters and shapes regardless of thickness. Laser cutters are more creative than traditional methods, which are restricted to certain cuts and patterns.

Agricultural Industry

The agriculture industry extensively uses laser cutting machines for cutting and molding of metals. Examples include aluminum, titanium, iron, stainless steel, and other so on. Laser cutters are much faster than traditional methods, such as water jet cutting.

They have the power to cut over 10 times thicknesses than what a water jet cutter does. Laser cutters produce clean and sharp edges, a feat traditional methods cannot achieve. This means less time post-processing and sharpening the edges.

Finally, agricultural equipment produced with laser-cutting machines can withstand harsh and unfavorable weather conditions.

Furniture Industry

The hallmark of the furniture business is creativity and the ability to think outside the box. As a furniture maker, create creative designs with a laser cutter as your cutting and engraving tool.

This means you can customize logos, designs, motifs, and drawings. Explore your creative mind, or bring your client's creative thoughts to light.

Compared to the traditional method of cutting and engraving, this is preferred because it is easy to use, requires less manual labor, and gives the best quality.

Kitchenware Industry

Laser-cutting machines are used to cut and engrave kitchenware. We all love personally customized and designed kitchen utensils, which can be made of glass, stainless steel, ceramic, or aluminum.

Customized kitchenware can also be given as gifts to your loved ones. It is a great flex to have customized kitchenware as it always makes it easy to identify.

Steel Industry

Laser-cutting machines are used to cut steel because of their high speed, precision, and accuracy. Steel can be cut into various plates, sizes, and shapes depending on the desired use. In addition to its cutting prowess, it can be used to weld two or more steel materials together.

Common Laser Cutting Materials

Before you invest in a laser cutting machine, you want to know if the technology works with your materials. Here are the common materials you can cut with a laser cutter:

Carbon Steel

Carbon steel is the combination of steel and varying concentrations of carbon, ranging from 0.12% to 2%. Carbon has a high melting point, so the higher the percentage of carbon present, the higher the melting point and the easier it is cut.

A fiber laser is the most preferred method for this type of material. The speed is solely dependent on the thickness of the material. The smaller the thickness, the faster the speed.

Copper

Fiber lasers are advisable for cutting copper, as they prevent copper discoloration. However, in the absence of fiber laser cutters, CO2 laser cutters can be used. Remember to spray the material with metals with the same wavelength as CO2 laser cutting machines.

Titanium

Titanium is strong and has a high melting point. Though challenging, it is possible to cut with the right settings. For the best results, use a CO2 laser in conjunction with oxygen or nitrogen. Laser-cut titanium is widely used because of its strength and lightweight nature.

Plastics

Another material that laser-cutting machines can handle is plastics. The best type for cutting is CO2, while diode is excellent for engraving. Some examples of plastics lasers can cut include acrylic styrene and polyoxymethylene.

Metals

Metal can be cut with either CO2 or diode laser cutters. Metals are the most common because they are used in virtually every industry for stop Examples include aluminum, brass, carbon steel, copper, and stainless steel.

Check this Toocaa Colorful Aluminium Engraving Round Tag.

Brass

Brass can be cut with either CO2 or fiber laser cutters. Fiber laser cutters are preferably used because of their short wavelength, which can melt brass easily. Use them slowly to get a precise, smooth, and accurate cut.

Aluminum

Aluminum is popular among the manufacturing and processing industries. It is easy to cut, so any laser-cutting machine can be used. The cutting or engraving style depends on the thickness of the aluminum and your expected results.

Wood

CO2, diode, and fiber laser cutters can handle soft, hard, and combined woods. For disparity, CO2 lasers are more powerful and efficient with minimal waste production. Diodes are the best option for pictures and any type of artwork because of their diversity of color options.

Check out this Toocaa Multi-shape Wooden Keychain.

Advantages of Laser Cutting System

High Speed

One of the selling points of laser cutting machines is their high speed, which makes cutting very fast. However, this high speed depends on the material's type, laser power, and thickness. This means it is slow when cutting through thick materials above 20 mm and with high heat conduction.

Environmentally Friendly

Laser-cutting machines are eco-friendly if managed well. They have compartments that receive dust and fumes released during the cutting or engraving. The machines are not made with many chemicals that can pollute the air, so they're safe and hazard-free for operators and employees.

Accuracy and Precision

Accuracy and precision are two main features of laser-cutting machines that distinguish them from traditional cutting methods. These features help ease creating, designing, and engraving tasks without sweating.

However, achieving this requires the right settings and mirror alignment to enhance precision and accuracy.

Low Maintenance Cost

The cost of maintaining laser-cutting machines is low if not misused. Clean the debris, tighten every loose bolt and knot, clean the bed, and carry out other basic maintenance regimens. This will increase the lifespan of your machine.

Disadvantages of Laser Cutting System

Despite the mouth-watering benefits of laser-cutting machines, you still want to learn the dark sides of laser cutting machines. Here is what to know:

It Is Expensive

The cost of purchasing a laser cutting machine is expensive. Installation and maintaining the operational costs are more expensive. It's almost three times the price of waterjet cutters or plasma cutters.

However, the price varies depending on the type of laser-cutting machine. Desktop diode laser engraving machines are quite affordable, and they can handle most of the engraving or cutting tasks that laser cutters can perform. You can check out the TOOCAA L2 laser engraving machine, and the accompanying TOOCAA STUDIO software is free.

Although the initial cost of purchase, installation, and maintenance may be high, the return on investment is good. That means you are sure of getting your money's worth quickly.

Limitations to Metal Thickness

Laser-cutting machines can cut materials regardless of their thickness. However, there's a limit to this, especially for inexperienced people. Most machines require an average of 15 to 20 millimeters. Anything above this must be done in the presence of a skilled machinist or under his/her guardianship.

Requires Technical Knowledge

Before handling a laser cutting machine for the first time, you must undergo a series of training sessions.

However, while in training and to ensure the continuity of your business, you may need to employ the services of a machinist or technical personnel. A machinist should be able to operate the machine, understand its settings, and interpret the results. Paying for the services of a machinist may be expensive for small-scale business owners.

Conclusion

It would be ignorant of a business owner or an individual to remain in the obsolete means of cutting and engraving. Technology has gone past that phase.

There are so many laser-cutting machine applications that it is unavoidable not to use them in industries. They include medical, automobile, furniture, aerospace, agricultural, and construction industries.

You will agree that laser-cutting machines are a blessing to the manufacturing industry. If you were unsure whether to purchase one, we hope you are now convinced that a laser cutting machine is a necessary tool to ease your job.

Are you looking for where to shop a quality laser cutting machine, accessories, and materials? Toocaa is the right place to go. You can also contact us with your enquiries about laser cutting machines.