Die einzige Möglichkeit, sicherzustellen, dass der Lasergravierer lange ohne Ausfälle funktioniert, ist die Wartung der Maschine. Dies wird normalerweise aus Mangel an Wissen versäumt. Die Leute wissen nicht, welche Art von Wartung durchgeführt werden muss.

Mit dieser Anleitung zur Wartung Ihres Lasergravierers können Sie sich einen Gravierer zulegen, der weniger häufig kaputt geht. So bekommen Sie mehr für Ihr Geld. Dies sind wichtige Wartungstipps für Lasergravierer und -schneider.

Die Wichtigkeit der Wartung eines Lasergravierers und -schneiders

Eine gut gewartete Lasermaschine läuft reibungslos und ohne Ausfälle. Dies ist nicht der einzige Grund, warum Sie die Lasermaschine regelmäßig warten sollten.

-

Für einen effizienten Betrieb

-

Verlängern Sie die Lebensdauer der Lasermaschine

-

Konstant hochwertige Ergebnisse

-

Vermeiden Sie hohe Kosten für die Reparatur oder den Austausch einer defekten Maschine

Kurz gesagt: Wenn Sie Ihren Laserschneider und -gravierer regelmäßig warten, haben Sie weniger Probleme und erfolgreichere Gravur- und Schneideprojekte. Wenn Sie einen Lasergravierer ohne Ausfälle haben möchten, müssen Sie einige Dinge beachten.

Empfehlungen zur regelmäßigen Reinigung

Es gibt Wartungsarbeiten, die monatlich durchgeführt werden müssen, und dann gibt es Reinigungsempfehlungen, die häufiger durchgeführt werden müssen. Wenn Sie diese Teile häufig überprüfen und vor jedem Gebrauch reinigen, wird jedes Mal eine hochwertige Gravur gewährleistet.

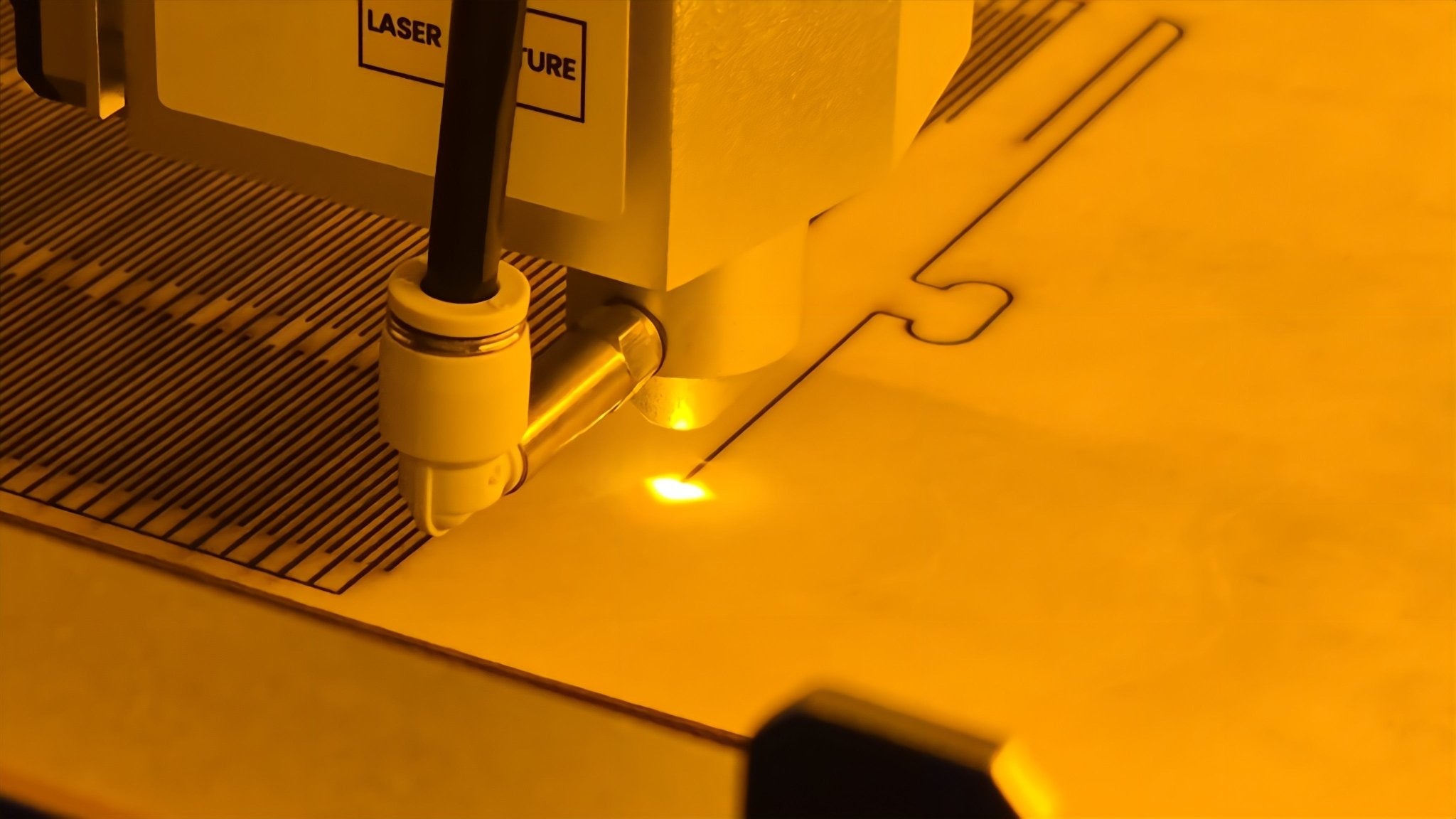

Luftunterstützte Düse

Die Hauptfunktion der Luftunterstützungsdüse besteht darin, die Linse sauber zu halten, um einen besseren Gravurschnitt zu erzielen. Diese Düse muss gereinigt werden, damit die Linse sauber bleibt. Sie müssen die Düse auf Verstopfungen und Staub überprüfen. Sie können sie mit einer kleinen Bürste oder Druckluft reinigen.

Laserspiegel und Linse

Beim regelmäßigen Gravieren und Schneiden werden die Laserspiegel und die Linse mit Schmutz beschmutzt. Feiner Staub kann die Qualität der Gravur beeinträchtigen. Große Schmutzmengen können außerdem zum Bruch der Laserlinse führen.

Sie können Linsenreinigungstücher verwenden, um die Oberfläche vorsichtig zu reinigen. Sie können zu diesem Zweck auch ein fusselfreies Tuch mit Isopropylalkohol verwenden. Achten Sie jedoch darauf, dass Sie die Linse und die Spiegel nicht zerkratzen.

(Screenshot von „CO2-Laserausrichtung und Reinigen von Laserlinsen und Spiegeln / Anfängerserie, Folge 5, von Make Tech, verfügbar auf YouTube)

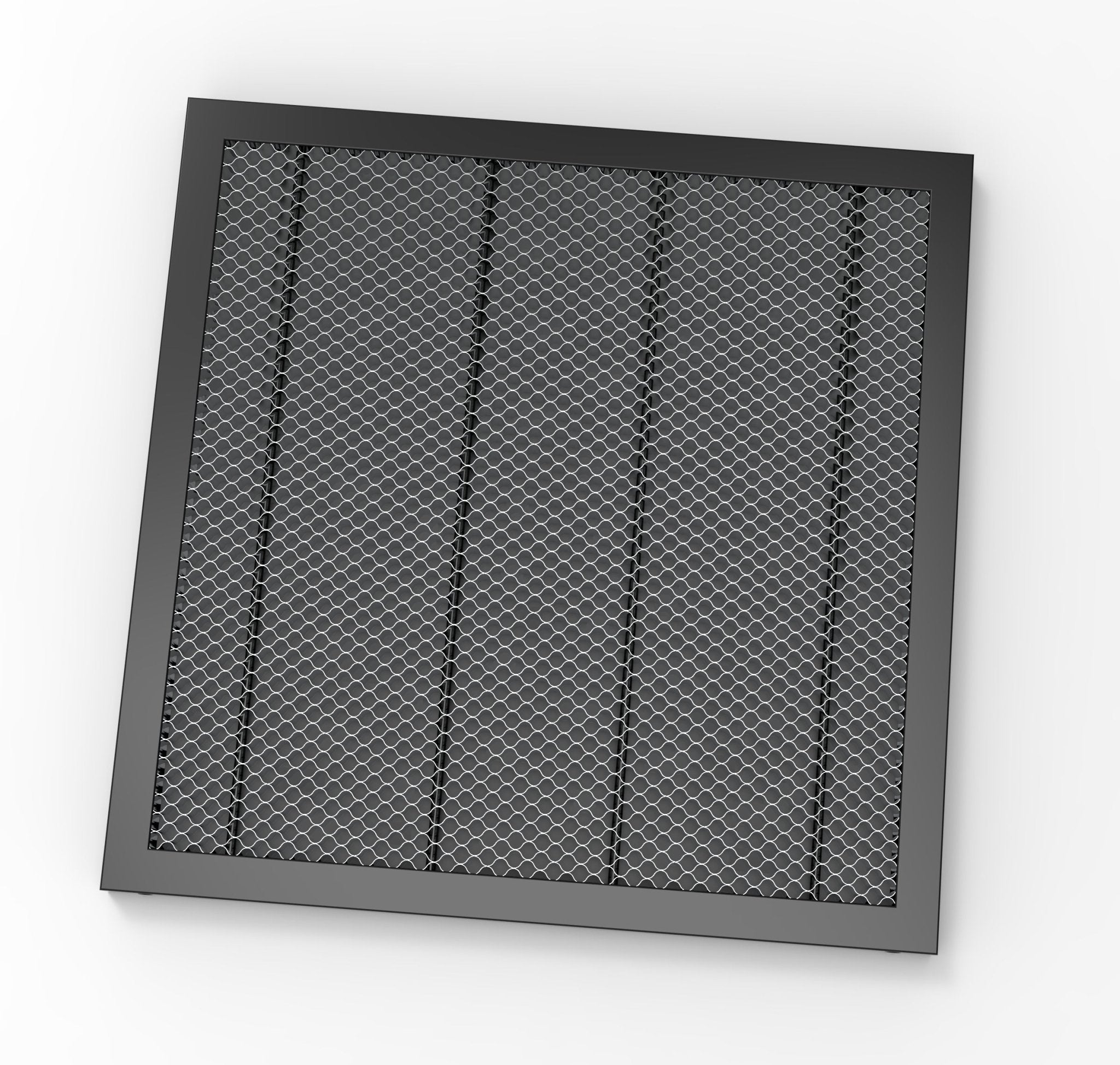

Die Abgasanlage

Die Funktion des Absaugsystems besteht darin, Rauch und Dämpfe beim Gravieren zu entfernen. Sie müssen es regelmäßig reinigen, indem Sie die Filter reinigen und austauschen. Ein defektes Absaugsystem an Ihrem Gravierer kann ein Gesundheitsrisiko darstellen.

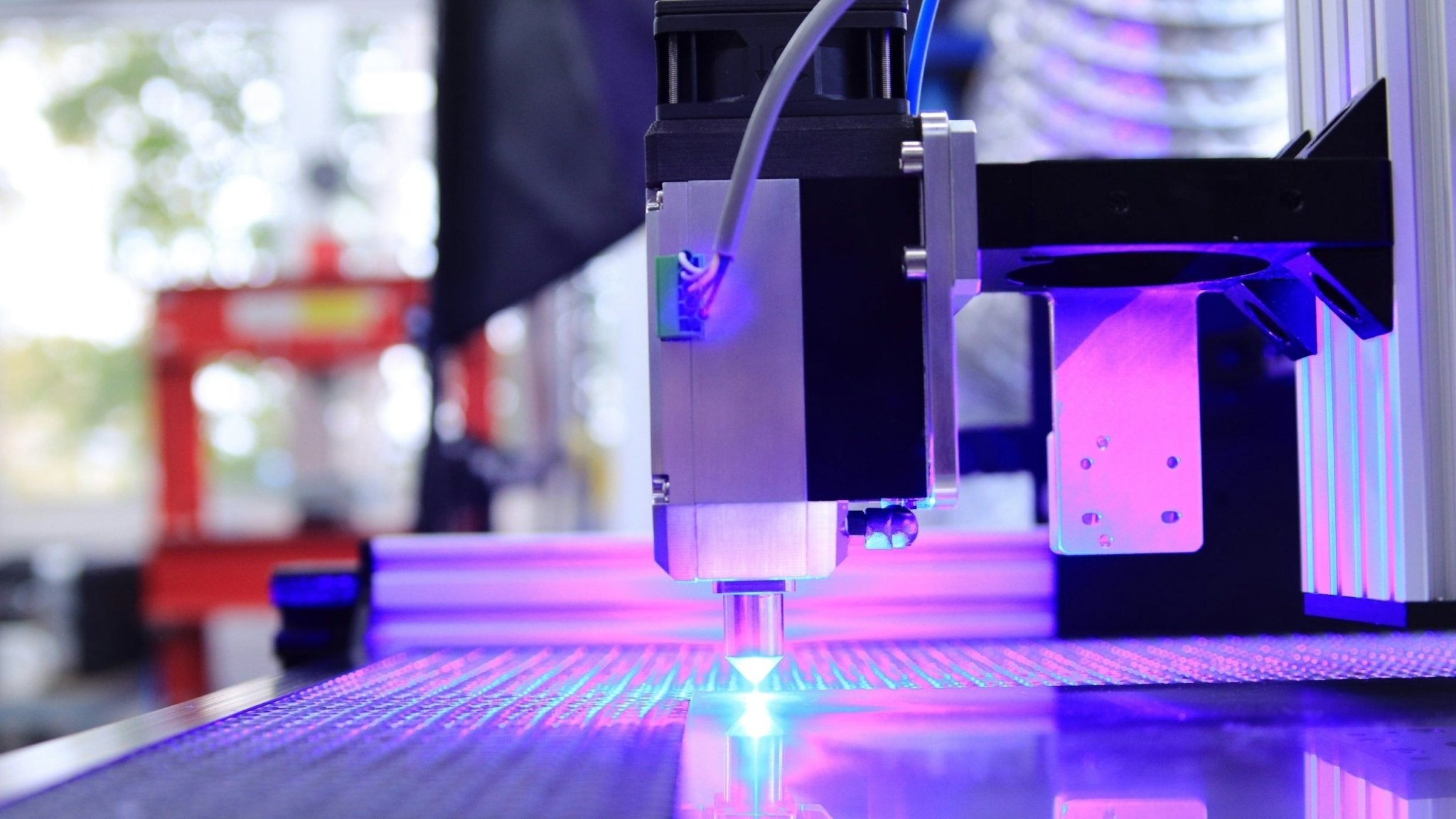

Wartung des Laserstrahls

Ein weiteres Wartungsverfahren, das regelmäßig durchgeführt werden muss, ist die Überprüfung des Laserstrahls. Er muss regelmäßig ausgerichtet werden. Wenn der Laserstrahl nicht ausgerichtet ist, kann die Gravur ungleichmäßig und ungeschickt aussehen.

Lesen und befolgen Sie die Ausrichtungsrichtlinien, die in der Bedienungsanleitung des Graveurs enthalten sind. Jeder Graveur hat seine eigene Methode, die angewendet werden muss. Beim Laserstrahl muss auch die Laserleistung kalibriert werden. Dies muss durchgeführt werden, wenn die Leistung und die Qualität der Gravur nachlassen.

Überprüfen Sie die Laserröhre regelmäßig

Ja, Sie müssen eine Laserröhre ersetzen, da sie mit der Zeit verschleißt. Sie können die Lebensdauer der Röhre jedoch durch regelmäßige Wartung verlängern. Dies ist eine Checkliste mit allen Dingen, die Sie bei der Reinigung einer Laserröhre überprüfen müssen:

-

Das Kühlsystem muss funktionsfähig sein.

-

Regelmäßiger Wasseraustausch im wassergekühlten System.

-

Halten Sie die Rohre frei von Feuchtigkeit und überprüfen Sie sie regelmäßig auf Risse oder Beschädigungen.

(Screenshot von „CO2-Lasergravierer-Wasserkühlung und Laserkühler. Anfängerserie, Folge 3, von Make Tech, verfügbar auf YouTube)

Software- und Firmware-Wartung

Dies ist etwas, was viele vergessen. Bei der Wartung geht es nicht nur um die Hardware einer Maschine. Auch die Software muss gewartet werden. Aus diesem Grund müssen Sie auch Software- und Firmware-Wartung durchführen.

Hier können Sie nach Updates der Firmware-Software suchen. Die Updates enthalten Fehlerbehebungen und Leistungsverbesserungen.

Erwägen Sie eine professionelle Wartung

Um die Lebensdauer Ihres Gravierers zu verlängern, sollten Sie am besten professionelle Wartungsdienste für Ihren Lasergravierer und -schneider beauftragen. Diese Wartungsexperten wissen, was zu reinigen ist und wie es richtig zu reinigen ist.

Möglicherweise müssen Sie für die Wartung eine Gebühr bezahlen, aber dann wissen Sie, dass Ihr Graveur auch reibungslos funktioniert. Stellen Sie einfach sicher, dass der von Ihnen beauftragte Service über die Erfahrung und Qualifikation für Ihren Graveurtyp verfügt.

Abschluss

Damit Ihr Lasergravierer lange Zeit einwandfrei funktioniert, müssen Sie ihn warten. Damit die Maschine einwandfrei läuft, müssen Sie einige Dinge reinigen und überprüfen. Wir haben uns die Zeit genommen, über die Reinigung und Wartung der meisten Lasergravierer zu sprechen.

Jeder Graveur hat unterschiedliche Wartungsanforderungen. Daher ist es wichtig, die Bedienungsanleitung zu studieren, um genau zu wissen, wie der Graveur gewartet werden muss. Mit dieser Anleitung können Sie Ihren Graveur nun selbst reinigen. Wenn Sie mit der Wartung nicht vertraut sind, sollten Sie vielleicht jemanden für diese Aufgabe beauftragen.

Und ich freue mich, Ihnen dieses Video zeigen zu können. Es ist wirklich eine gute, einfache Videoanleitung für Anfänger. In dieser Folge führt Sie der Youtuber durch den entscheidenden Prozess der Spiegelausrichtung und Reinigung der Linse, die für die Aufrechterhaltung der Präzision und Sicherstellung gleichbleibender Ergebnisse unerlässlich sind.