In manchen Fällen müssen Sie sich zwischen einer Laserschneidmaschine und einem Lasergravierer entscheiden. Es gibt jedoch einige Maschinen, die als 2-in-1-Geräte bekannt sind. Sie sind Gravierer und Schneidegerät. Was ist der Unterschied und warum sollten Sie beide Funktionen in Betracht ziehen?

Wir werden uns die Unterschiede und Anwendungsunterschiede zwischen Lasergravierer und -schneider ansehen. So fällt es Ihnen leichter zu entscheiden, welches Gerät Sie für Ihr neues Unternehmen benötigen.

Laserschneiden und -gravieren verstehen

Als Erstes muss man verstehen, was ein Laserschneider und ein Lasergravierer sind. Manche Leute wissen nicht, dass es mittlerweile Industriemaschinen zum Schneiden und Gravieren gibt, die klein genug für den Heimgebrauch sind. Wenn Sie an eine Lasermaschine denken, denken Sie normalerweise an große und gefährliche Maschinen. Lassen Sie uns zunächst sicherstellen, dass Sie diese Maschinen verstehen.

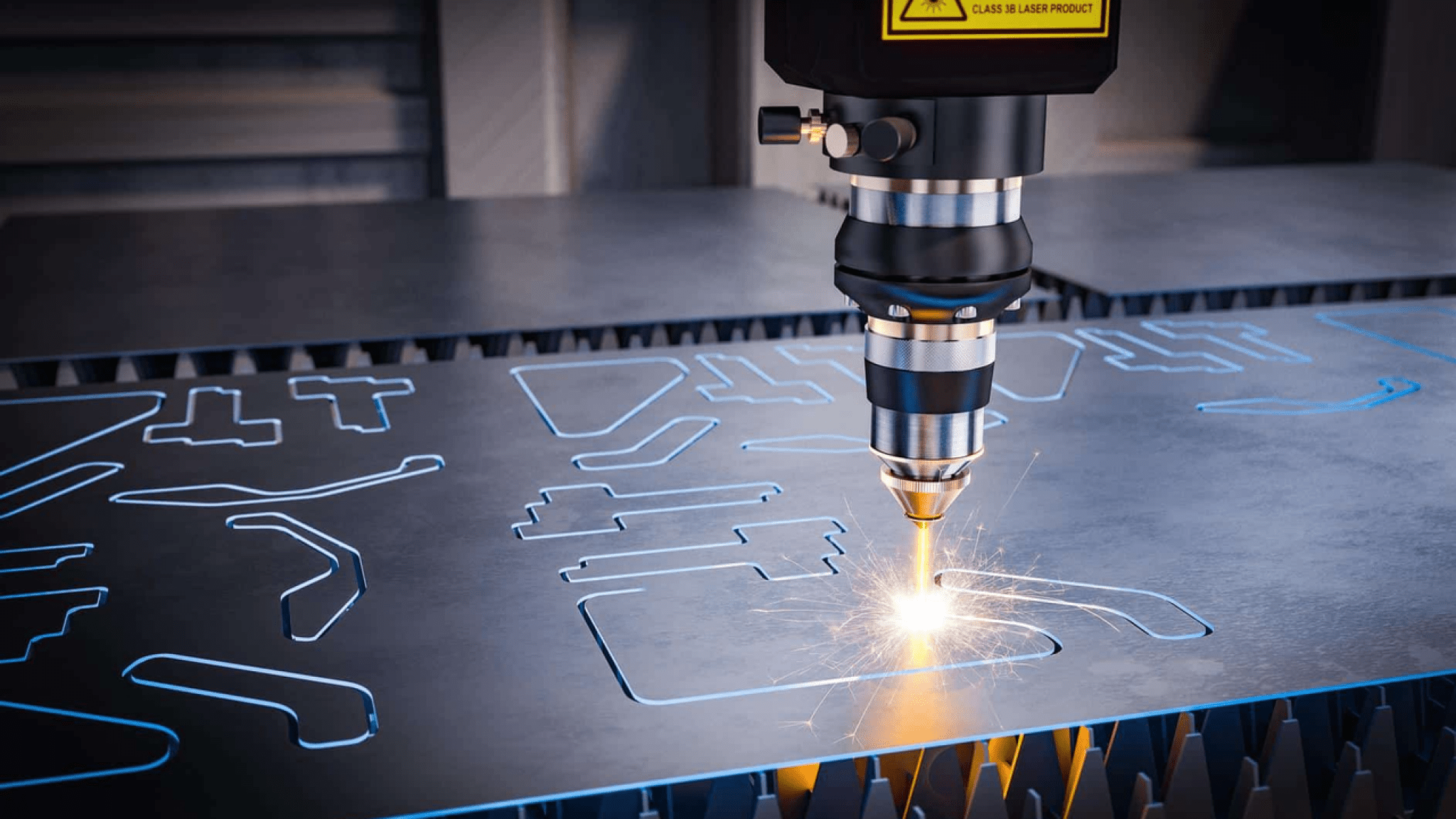

Laserschneiden

Laserschneidgeräte gibt es in verschiedenen Größen und mit unterschiedlichen Funktionen. Es gibt große Industriemaschinen und kleinere Maschinen für Menschen, die das Schneiden zu Hause als Hobby betreiben. Im Allgemeinen sind diese Lasermaschinen Hochleistungsmaschinen, die verschiedene Materialien schneiden können. Sie werden hauptsächlich im Automobilbau, in der Elektronik und im Kunsthandwerk verwendet. Ihre Preise reichen von erschwinglich bis extrem teuer.

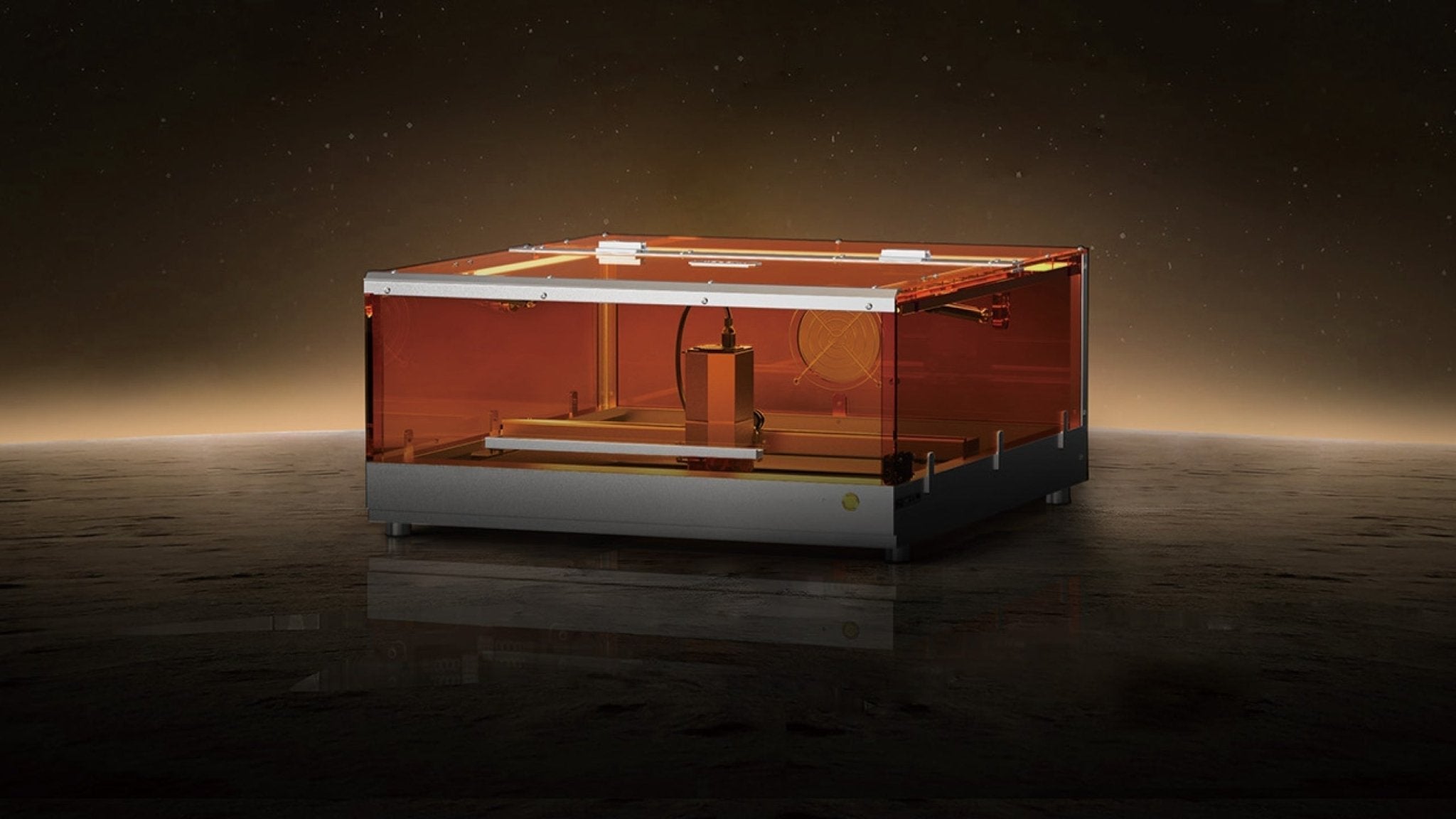

Lasergravur

Anders als die meisten Leute denken, ist Lasergravur etwas völlig anderes als Schneiden. In manchen Fällen können Sie dieselbe Maschine verwenden, aber die Anwendungen sind unterschiedlich. Beim Gravieren ätzt der Laserstrahl Muster in Materialien. Er kann ein Muster auf dem Computer lesen und auf das Material kopieren, das Sie gravieren möchten.

Anwendungen der Gravier- und Schneidelasermaschinen

Um zu entscheiden, welche Lasermaschine Sie benötigen, müssen Sie die unterschiedlichen Anwendungen von Fräser und Gravierer kennen. Hier sehen Sie, dass Fräser und Gravierer zwei völlig unterschiedliche Aufgaben erfüllen. Dies sind die Hauptanwendungen oder -verwendungen für Gravierer und Laserschneider.

Laserschneider

Die Hauptanwendung eines Laserschneiders besteht darin, verschiedene Arten von Materialien präzise zu schneiden. Dies ist für Herstellungsprozesse oder Kunsthandwerk gedacht. Weitere Anwendungen für diese Maschinen sind:

-

Präzises Schneiden durch zähe und harte Materialien.

-

Erstellen Sie individuelle Schilder, Buchstaben und sogar Logos aus Materialien wie Holz, Metall oder Acryl.

-

Erstellen von Schmuck durch Ausschneiden von Formen unterschiedlicher Größe für den Schmuck.

-

Es kann in Hobbys verwendet werden, um Kunstwerke und Formen aus verschiedenen Materialien zu schneiden.

Lasergravierer

Die Hauptanwendung eines Graveurs besteht darin, ein Produkt zu brandmarken oder ihm eine persönliche Note zu verleihen. Dies können Trophäen und Schilder auf Holz oder Metall sein. Weitere Anwendungen sind:

-

Gravieren Sie detaillierte Designs in verschiedene Materialien, einschließlich Glas, um einzigartige Kunstwerke zu schaffen.

-

Beschriften oder Hinzufügen von Seriennummern auf Produkten zur Markenbildung oder Identifizierung.

-

Hobby-Graveure können auch zum Personalisieren von hergestellten Gegenständen verwendet werden.

Die Unterschiede zwischen Laserschneiden und Lasergravieren

Ja, wie wir bereits gesagt haben, gibt es einen Unterschied zwischen Schneiden und Gravieren. Insbesondere, wenn dies mit einer Lasermaschine erfolgt. Dies sind die häufigsten Unterschiede zwischen diesen beiden Methoden.

Die Schneidmethode auf Material

Der Hauptunterschied liegt in der Schneidmethode der Materialien.

- Laserschneider

Beim Laserschneiden schneidet die Maschine mithilfe eines Lasers vollständig durch das Material. Bei den meisten Lasermaschinen ist der Laser sicher. Er kann Materialien wie Acryl, Holz, Metall und Glas schneiden. Verschiedene Maschinen können unterschiedliche Materialarten schneiden.

- Lasergravierer

Anders als der Fräser schneidet der Graveur nicht vollständig durch das Material. Er hinterlässt Markierungen auf dem Material, die sich auf verschiedenen Materialien in ein Wort oder sogar ein Bild verwandeln. Die Hauptanwendung besteht darin, Designs in Materialien zu erstellen.

Leistung und Geschwindigkeit

Sie verwenden zum Schneiden und Gravieren möglicherweise dieselbe Maschine, aber Geschwindigkeit und Leistung unterscheiden sich.

- Laserschneider

Der Fräser schneidet langsam, um einen präzisen Schnitt zu gewährleisten. Der andere Grund für eine langsame Schnittgeschwindigkeit besteht darin, sicherzustellen, dass das Material dabei nicht beschädigt wird. Die Kraft ist extrem stark, um das Material mit einem Schnitt zu durchschneiden.

- Lasergravierer

Der Graveur arbeitet schneller. Das liegt daran, dass kein großer Schnitt gemacht werden muss. Und aus dem gleichen Grund ist die Kraft der Gravur nicht so hoch wie beim Fräser. Selbst wenn sie die gleichen Materialien verwenden.

Abschluss

Laserschneidmaschinen können teuer sein. Deshalb müssen Sie sicherstellen, dass Sie in den richtigen Maschinentyp investieren. Sie können keinen Gravierer kaufen, wenn Sie tatsächlich Materialien schneiden müssen.

Bevor Sie Ihr erstes Gerät kaufen, sollten Sie sich überlegen, wofür Sie das Gerät verwenden möchten, wie viel Platz zur Verfügung steht und welche Materialien Sie schneiden oder gravieren möchten. In den meisten Fällen ist der Laserstrahl ungefährlich, dennoch ist es sinnvoll, eine Schutzbrille zu tragen.

Sie können eine Lasermaschine zu Hause oder in einem großen Unternehmen verwenden. Sie müssen nur so viel wie möglich über die Unterschiede zwischen Schneiden und Gravieren wissen. So vermeiden Sie, Geld für den Kauf von etwas zu verschwenden, das Sie eigentlich nicht verwenden können.

Nachdem ich nun den Unterschied zwischen diesen beiden Laser-Arbeitsmethoden kenne, freue ich mich, Ihnen dieses Video zeigen zu können! Das Video erklärt den Prozess der Lasergravur auf verständliche Weise. Zunächst wird ein Bild vorbereitet und dann mit dem Druckbefehl an den Lasergravierer gesendet. Der Laser kann das Bild auf eine Vielzahl von Materialien gravieren, darunter Holz, Laminat, Acryl, Textilien, Papier und Glas.