Der Besitz eines Lasergravierers ist eine großartige Investition für Ihre Projekte, aber die richtige Wartung ist wichtig, damit er reibungslos läuft. Regelmäßige Pflege trägt dazu bei, dass Ihre Maschine länger hält und besser funktioniert.

Hier sind einige einfache Wartungstipps, um Ihren Lasergravierer in Topform zu halten:

1. Reinigen Sie die Linse und die Spiegel regelmäßig

Die Linse und die Spiegel fokussieren und lenken den Laserstrahl. Wenn sie schmutzig sind, verliert der Laser an Leistung und die Gravurqualität wird beeinträchtigt. Reinigen Sie sie alle 10-20 Betriebsstunden.

So reinigen Sie: Verwenden Sie ein weiches Tuch oder Linsenreinigungstücher mit einer milden Reinigungslösung. Vermeiden Sie scheuernde Materialien, die die Oberfläche zerkratzen können.

2. Alle Schrauben prüfen und festziehen

Mit der Zeit können sich durch Vibrationen die Schrauben an Ihrem Lasergravierer lösen. Lose Teile können zu Fehlausrichtungen führen und die Gravurqualität beeinträchtigen. Überprüfen Sie die Schrauben regelmäßig und ziehen Sie sie fest.

So überprüfen Sie es: Suchen Sie nach Schrauben am Laserkopf, den Schienen und dem Rahmen. Verwenden Sie einen Schraubendreher, um sicherzustellen, dass alles fest sitzt.

3. Bewegliche Teile schmieren

Ihr Lasergravierer hat bewegliche Teile wie Schienen, Motoren und Zahnräder. Diese Teile müssen richtig geschmiert werden, damit sie sich reibungslos bewegen. Mangelnde Schmierung kann zu Verschleiß dieser Komponenten führen.

So schmieren Sie: Verwenden Sie vom Hersteller empfohlenes Maschinenöl oder Fett. Tragen Sie es alle 1-2 Monate auf die Schienen und beweglichen Teile auf.

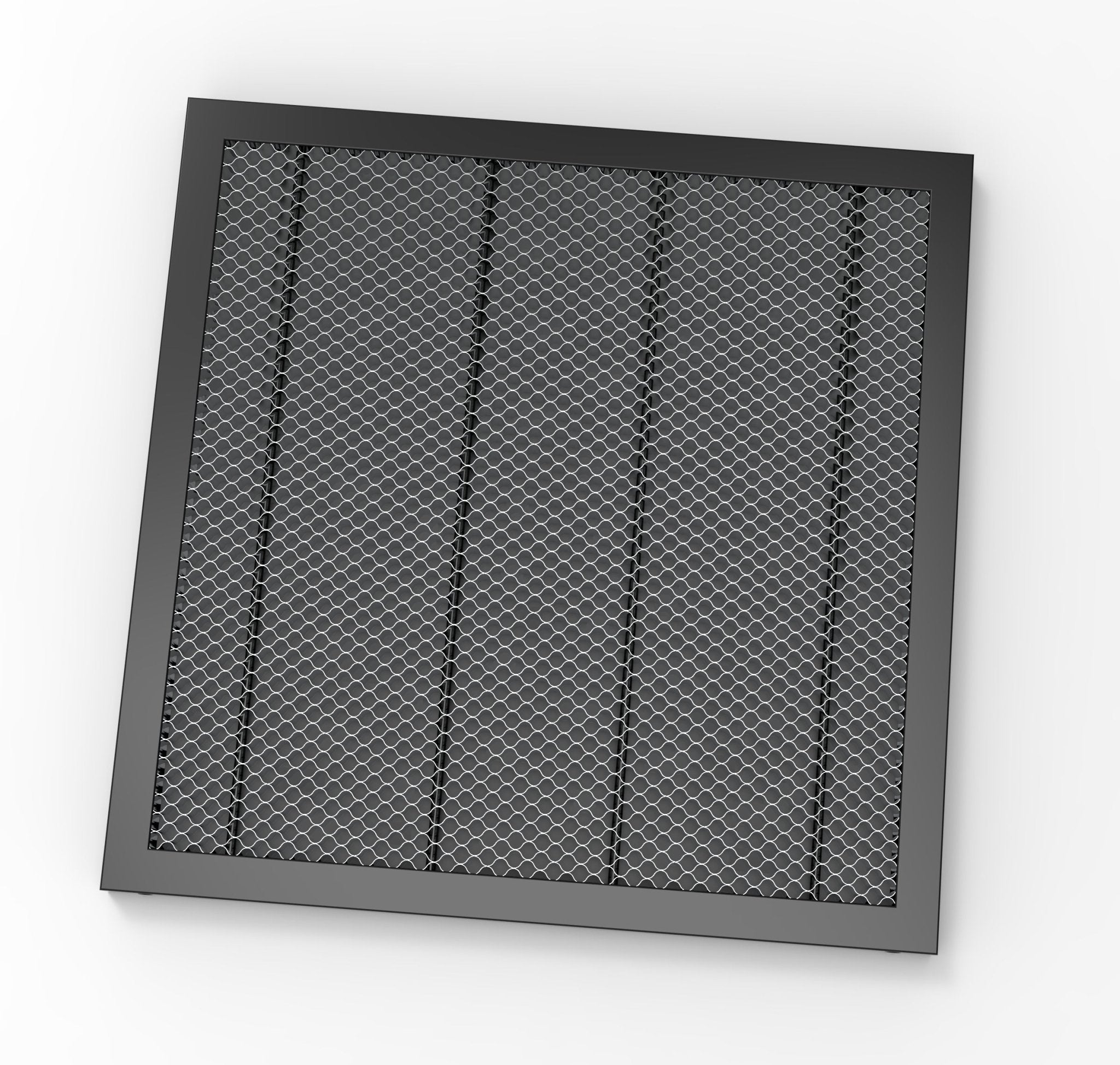

4. Reinigen Sie das Bett und die umliegenden Bereiche

Auf dem Gravurbett und den umliegenden Bereichen können sich Staub, Schmutz und Ablagerungen ansammeln. Diese können sowohl die Gravurqualität als auch den Luftstrom der Maschine beeinträchtigen.

So reinigen Sie: Entfernen Sie Schmutz mit einem Staubsauger oder Druckluft vom Bett und den umliegenden Bereichen. Wischen Sie die Oberflächen mit einem sauberen Tuch ab.

5. Überprüfen Sie die Riemenspannung

Die Riemen Ihres Lasergravierers dienen zur Bewegung des Laserkopfes. Mit der Zeit können sich die Riemen lockern, was dazu führen kann, dass Schritte übersprungen werden oder die Gravurergebnisse schlecht sind.

So prüfen Sie: Drücken Sie leicht auf den Riemen, um zu prüfen, ob er sich zu leicht bewegt. Wenn er sich locker anfühlt, passen Sie die Spannung mit den Spannschrauben an.

6. Überwachen Sie die Laserröhre

Die Laserröhre ist eine der kritischsten Komponenten des Gravierers. Sie wird mit der Zeit durch den Gebrauch verschleißen und eine abgenutzte Röhre kann zu einer schwachen oder inkonsistenten Laserleistung führen.

So überwachen Sie: Behalten Sie die Leistung der Röhre im Auge. Wenn Sie eine Abnahme der Gravurleistung feststellen, ist es möglicherweise an der Zeit, die Röhre auszutauschen.

7. Software und Firmware aktualisieren

Wenn Sie die Software und Firmware Ihres Graveurs auf dem neuesten Stand halten, stellen Sie die Kompatibilität mit Ihren Designs sicher und sorgen dafür, dass Ihr Graveur effizient arbeitet.

So führen Sie ein Update durch: Suchen Sie regelmäßig auf der Website des Herstellers nach Software- oder Firmware-Updates. Folgen Sie den Anweisungen zum Installieren der Updates.

8. Sorgen Sie für ausreichende Belüftung

Beim Lasergravieren entstehen Dämpfe, insbesondere bei der Arbeit mit Materialien wie Holz oder Acryl. Eine ausreichende Belüftung ist wichtig, um die Maschine und den Arbeitsbereich sicher zu halten.

So lüften Sie: Verwenden Sie einen Rauchabzug oder sorgen Sie für eine gute Belüftung Ihres Arbeitsplatzes. Dadurch werden schädliche Dämpfe entfernt und Ihre Gesundheit sowie die Ihres Graveurs geschützt.

9. Halten Sie den Graveur bedeckt

Wenn Sie Ihren Gravierer nicht verwenden, decken Sie ihn ab, um ihn vor Staub, Schmutz und Feuchtigkeit zu schützen. Dieser einfache Schritt hilft, unnötigen Verschleiß zu vermeiden und hält Ihre Maschine sauber.

So decken Sie es ab: Verwenden Sie ein weiches Tuch oder eine Maschinenabdeckung, um Ihren Gravierer vor Schmutz zu schützen.

Abschließende Gedanken zur Wartung von Lasergravierern

Regelmäßige Wartung ist der Schlüssel, um sicherzustellen, dass Ihr Lasergravierer in hervorragendem Zustand bleibt. Wenn Sie diese einfachen Tipps befolgen – Reinigen der Linse, Überprüfen der Riemen, Schmieren beweglicher Teile und Kontrollieren des Kühlsystems – können Sie dafür sorgen, dass Ihre Maschine viele Jahre lang wie neu funktioniert. Konsequente Pflege verbessert die Gravurqualität und verlängert die Lebensdauer Ihres Lasergravierers, sodass Sie das Beste aus Ihrer Investition herausholen können.

Für die Wartung von TOOCAA L2 haben wir eine Reihe von Video-Tutorials für Benutzer, darunter Videos zum Ersetzen, Reinigen und Anpassen. Das Video ist wie folgt:

Und für andere Reinigungs- und Wartungsarbeiten an der Maschine habe ich auch eine Anleitung gefunden, die für Anfänger nützlich ist. Befolgen Sie die einfachen Schritte in diesem Video, um die Spitzenleistung Ihres Lasers sicherzustellen und kostspielige Wartungskosten zu reduzieren oder zu vermeiden.